Preparation method of multifunctional membrane containing modified boehmite

A boehmite and multifunctional technology, which is applied in the field of preparation of modified boehmite-containing multifunctional films, can solve the problems of strong water solubility and loss, and achieve the effect of convenient graft modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a multifunctional membrane containing modified boehmite, the method comprising the following steps:

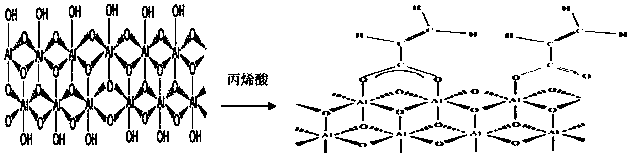

[0031] (1) 50 grams of boehmite (0.83mol) was added to 800 milliliters of distilled water to disperse, and ultrasonically treated, 3 grams of hydroquinone was added after 5 minutes; then slowly added methacrylic acid (154g, 1.8mol ), the reaction was carried out for 20 hours under stirring at 70° C., the solid product was washed with deionized water, and finally dried in vacuum at 50° C. for 20 hours to obtain esterified boehmite.

[0032] (2) Mix 20g of polyethersulfone, 1g of esterified boehmite, 1g of polyvinylpyrrolidone and 78g of dimethylacetamide, stir at 60°C for 24 hours to form a solution, use water as the gel medium to form a film, and the evaporation time for 30 seconds, and the membrane was soaked in water for 24 hours.

[0033] (3) Prepare 3wt% acrylic acid, 0.015wt% potassium persulfate, and 0.5wt% ethylene glycol aqueous solution ...

Embodiment 2

[0035] A method for preparing a multifunctional membrane containing modified boehmite, the method comprising the following steps:

[0036] (1) Disperse 10.0g of boehmite in 250mL of xylene, add 48g of acrylic acid, reflux the mixture in xylene at 138-145°C for 72 hours, distill off the xylene under reduced pressure, wash the solid with ether to remove impurities, and dry it to obtain White esterified boehmite powder.

[0037] (2) Mix 24g polyvinyl chloride, 5g esterified boehmite, 8g polyethylene glycol and 73g N-methylpyrrolidone, stir at 60°C for 24 hours to form a solution, use water as the gel medium to form a film, and the evaporation time For 10 seconds, the film was soaked in water for 26 hours.

[0038](3) Prepare 800 milliliters of ethylene glycol aqueous solution containing 3wt% sodium p-styrenesulfonate, 0.015wt% ammonium persulfate, and 0.5wt%, pour it into a film-filled container, ventilate nitrogen, and heat to 65- 70°C, reacted for 4 hours, then washed with wa...

Embodiment 3

[0040] A method for preparing a multifunctional membrane containing modified boehmite, the method comprising the following steps:

[0041] (1) 50 grams of boehmite (0.83mol) was added to 800 milliliters of distilled water to disperse, and ultrasonically treated, 3 grams of hydroquinone was added after 5 minutes; then slowly added methacrylic acid (154g, 1.8mol ), the reaction was carried out for 20 hours under stirring at 70° C., the solid product was washed with deionized water, and finally dried in vacuum at 50° C. for 20 hours to obtain esterified boehmite.

[0042] (2) Mix 16g of polyacrylonitrile, 0.5g of esterified boehmite, 1g of polyvinylpyrrolidone and 82.5g of dimethyl sulfoxide, stir at 60°C for 24 hours to make a solution, use water as the gel medium to form a film, evaporate The time is 30 seconds, and the membrane is soaked in water for 24 hours.

[0043] (3) Use 500 milliliters of aqueous solution to prepare methacrylic acid containing 3wt%, 0.015wt% sodium per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com