Strontium titanate dielectric layer based meta-material wave absorbing device and manufacturing method thereof

A medium layer, metamaterial technology, applied in electrical components, magnetic/electric field shielding, antennas, etc., can solve problems such as the inability to meet active tuning, and achieve the effect of promoting development and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

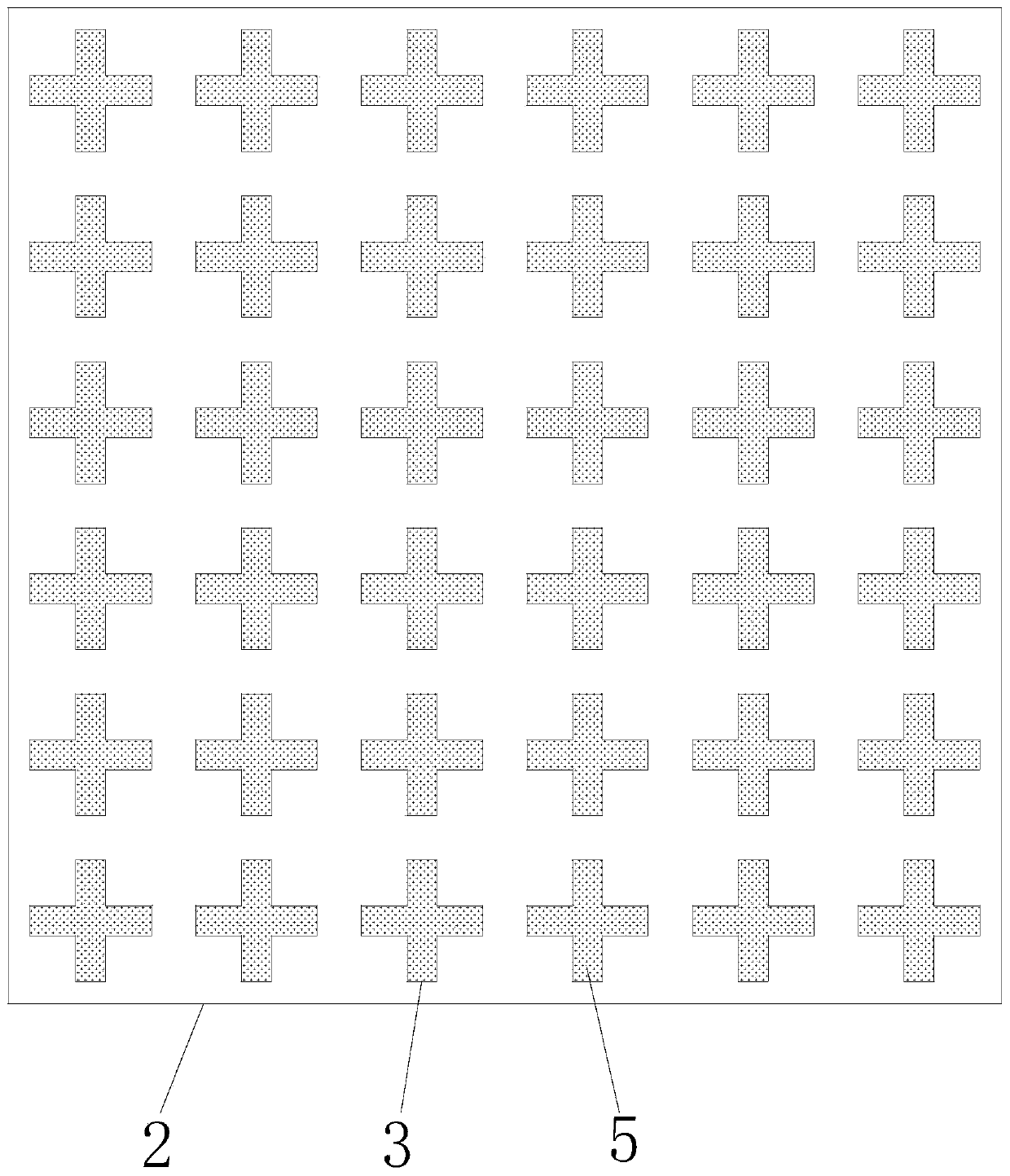

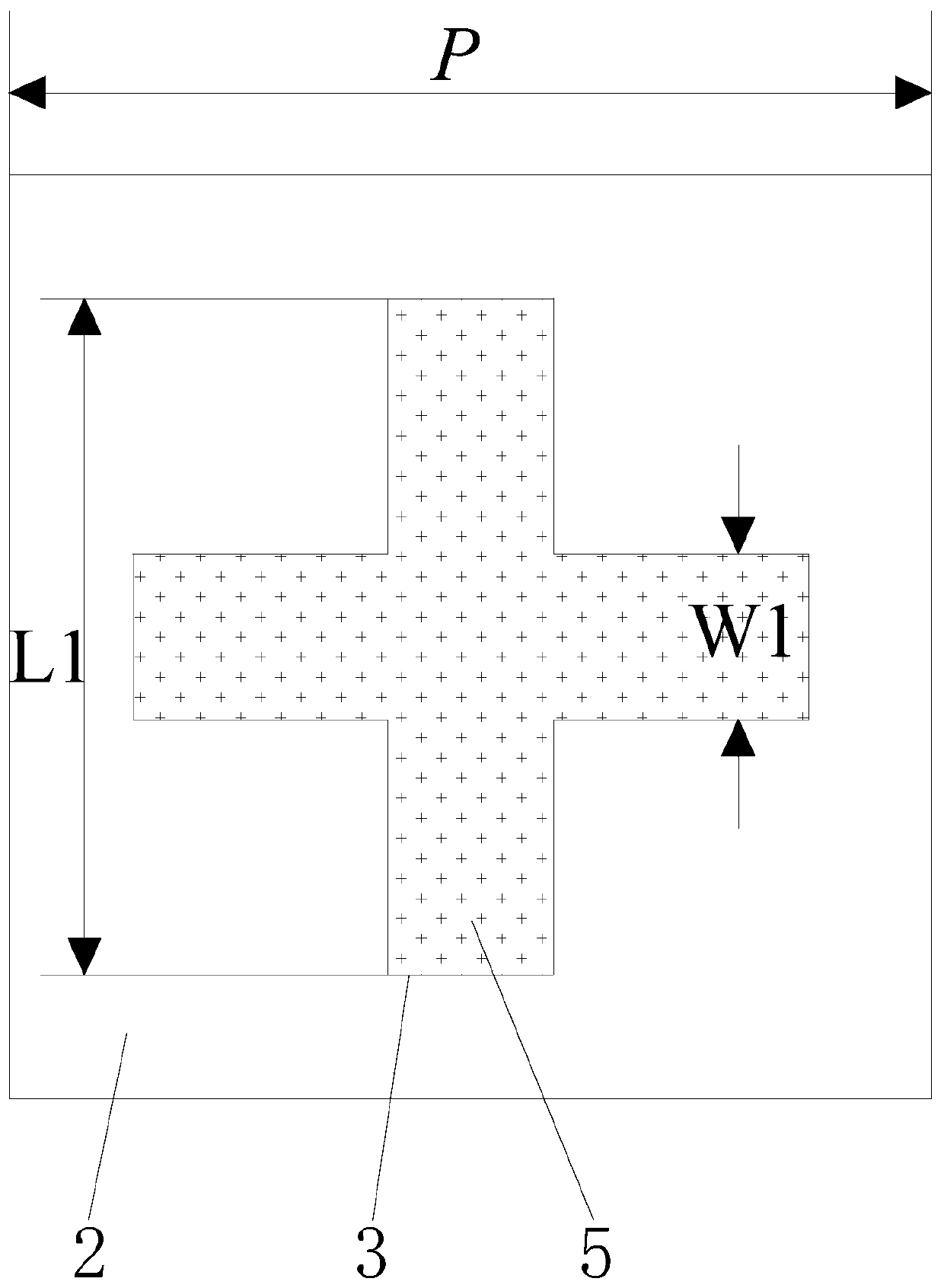

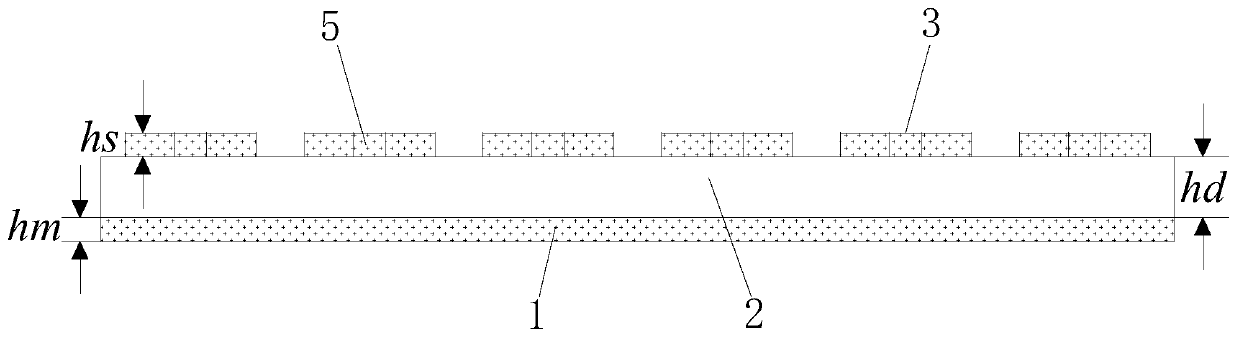

[0041] see figure 1 , figure 2 as well as image 3 , this embodiment provides a metamaterial wave absorber based on a strontium titanate dielectric layer, which includes a bottom structure 1 , a middle dielectric layer 2 and a top resonant structure 3 . The wave absorber of this embodiment is applied to one or more devices of stealth devices, terahertz imaging devices, terahertz detection devices, electromagnetic wave detection and control devices, and solar cells, and can also be applied to other various devices that need to be tuned or device.

[0042] The underlying structure 1 includes at least one layer of metal film, and the metal film is a continuous film. The metal film has a conductivity of 5.8×10 7 S / m copper is made, and its thickness can be greater than the skin depth of electromagnetic waves in the metal. In this embodiment, the thickness hm of the underlying structure 1 is 0.3 um and is rectangular. The underlying structure 1 can be formed by stacking mult...

Embodiment 2

[0054] This embodiment provides a metamaterial wave absorber based on a strontium titanate dielectric layer, which adds a temperature control unit on the basis of Embodiment 1. The temperature control unit is used to adjust the temperature of the intermediate medium layer 2 , specifically to raise and lower the temperature of the intermediate medium layer 2 . In this way, when it is necessary to adjust the absorbing frequency band or absorbing intensity of the absorber in practical applications, the temperature of the intermediate dielectric layer 2 can be adjusted through the temperature control unit, so that the SrTiO 3 The ambient temperature of the material changes, thereby changing the absorbing frequency band or absorbing intensity of the absorber. Therefore, when other devices or devices are equipped with the absorber of this embodiment, the device or device only needs to control the temperature control unit to realize the automatic adjustment of the absorber's absorbin...

Embodiment 3

[0056] This embodiment provides a method for manufacturing a metamaterial wave absorber based on a strontium titanate dielectric layer, which is used to manufacture the metamaterial wave absorber based on a strontium titanate dielectric layer in Embodiment 1 or Embodiment 2. The method includes the following steps:

[0057] 1. According to the shape of the underlying structure 1, excavate a positioning groove on the base material whose depth is not less than the sum of the thicknesses of the underlying structure 1, the intermediate dielectric layer 2 and the top resonant structure 3;

[0058] 2. Starting from the bottom of the positioning groove, coat at least one layer of metal film, and after the metal film is shaped, pour liquid SrTiO into the positioning groove 3 material to form a solid intermediary layer 2;

[0059] 3. Delineate multiple positioning areas arranged in an array on the intermediate dielectric layer 2, and the multiple positioning areas correspond to multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com