Flexible composite solid-state electrolyte, full-solid-state lithium-ion battery and preparation method thereof

A solid-state electrolyte, lithium-ion battery technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problem of unfavorable dispersion uniformity of sulfide electrolyte and polymer electrolyte, inability to form flexible solid electrolyte, restricting flexibility It can improve the conductivity and electrochemical stability of lithium ions, improve the cycle life and energy density, and achieve the effect of good electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the flexible composite solid electrolyte comprises the following steps:

[0052] Grinding the mixture of sulfide solid electrolyte and its modification, thermoplastic polymer and its modification and lithium salt.

[0053] In some preferred embodiments of the present invention, the grinding is wet grinding, including ball milling, sand milling or wet milling.

[0054] In some preferred embodiments of the present invention, the grinding solvent used in the wet grinding includes acetonitrile, N-methylpyrrolidone, dimethoxyethane, tetrahydrofuran, ethyl acetate, dimethyl carbonate, dimethyl ethyl One or a combination of amides, ethyl propionate, N-methylformamide, dimethylformamide, acetone, ethanol and toluene.

[0055] In some preferred embodiments of the present invention, the mass of the grinding solvent is 2 to 8 times the mass sum of the sulfide solid electrolyte and its modified product, the thermoplastic polymer and its modified product, ...

Embodiment 1

[0071] As a specific solution of the present invention, the flexible composite solid electrolyte of this embodiment includes crystalline Li 10 GeP 2 S 12 , thermoplastic polymer PEO (molecular weight 600,000) and lithium salt LiTFSI. The sulfide solid electrolyte is selected from crystalline 5Li 2 S-P 2 S 5 -GeS 2 , namely Li 10 GeP2 S 12 ; The thermoplastic polymer is selected from PEO; the lithium salt is selected from LiTFSI; the organic solvent is selected from ACN.

[0072] The preparation process of the flexible composite solid electrolyte in this example is as follows:

[0073] Crystalline Li 10 GeP 2 S 12 , PEO (molecular weight: 600,000), and LiTFSI are mixed, added to ACN solvent and mixed by high-energy ball milling. Among them, Li 10 GeP 2 S 12 The proportion of solid electrolyte is 80wt%, the proportion of PEO polymer and LiTFSI lithium salt is 20wt%; the molar ratio of polymer monomer and lithium ion in lithium salt is 18:1; the mass of ACN organic...

experiment example 1

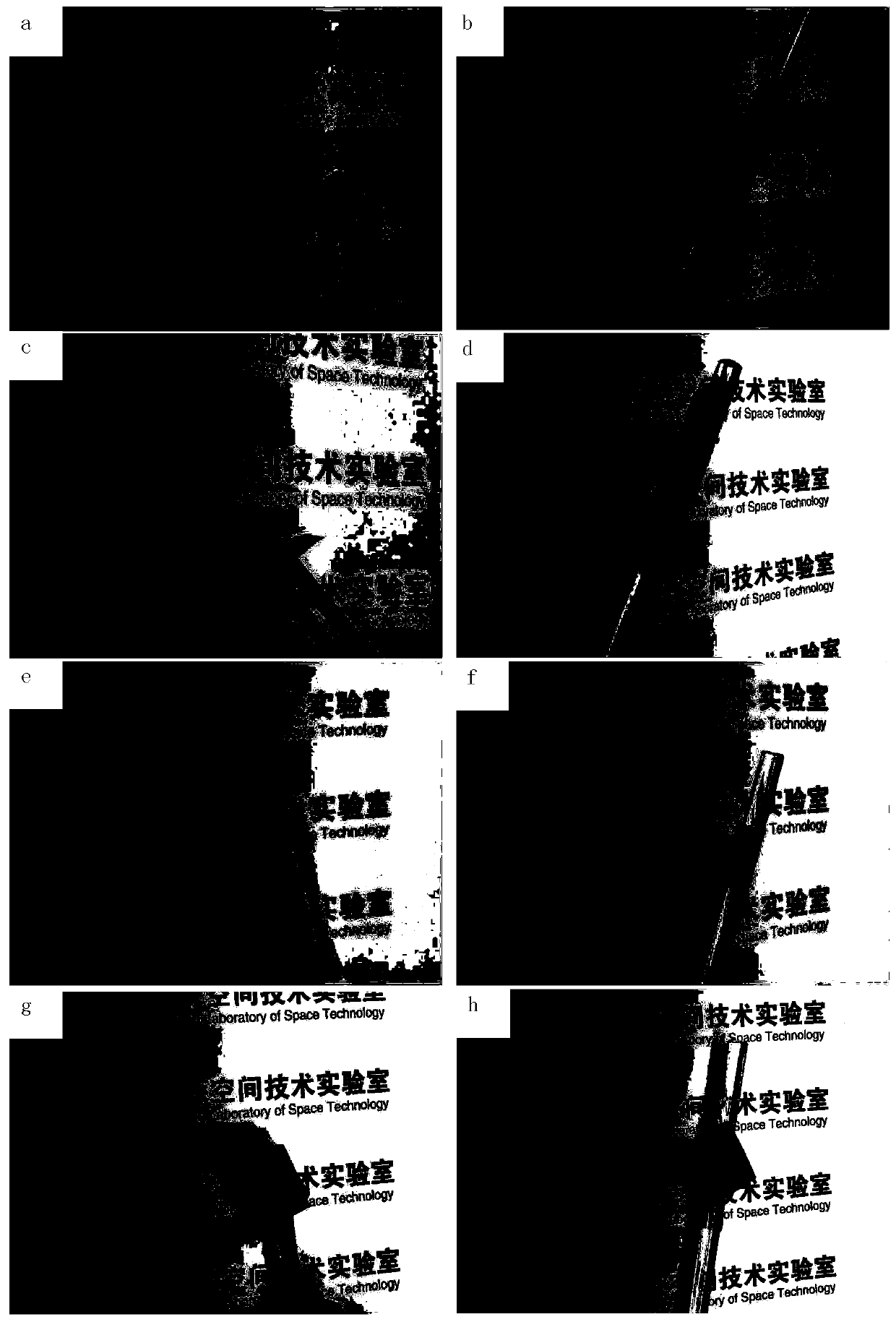

[0079] Experimental example 1 Flexible display and ionic conductivity test of flexible composite solid electrolyte

[0080] Coat the flexible composite solid electrolyte slurry on a glass plate, and after drying naturally, place the glass plate in a muffle furnace for drying at 50°C, and then remove the prepared flexible composite solid electrolyte from the glass plate, Obtain flexible composite solid electrolyte PEO-LiTFSI-80wt%LGPS (LGPS is the abbreviation of flexible composite solid electrolyte) (see figure 1 middle e and f). Comparative polymer solid electrolyte PEO-LiTFSI (see figure 1 In a and b), the flexible composite solid electrolyte can also be bent and folded.

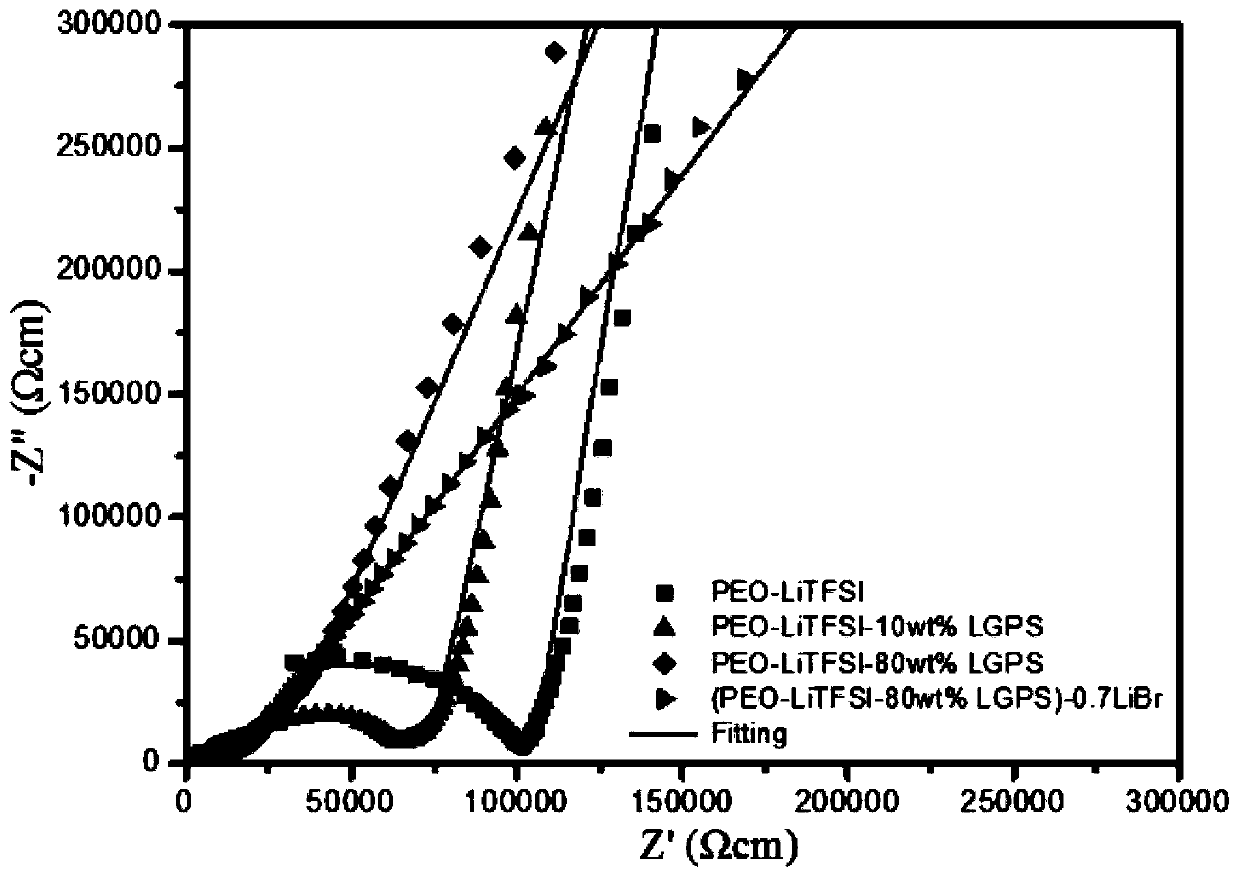

[0081] Use a slicer to obtain a disc-shaped flexible composite solid electrolyte PEO-LiTFSI-80wt% LGPS with a diameter of 12 mm and a thickness of 164 μm. Add a stainless steel sheet to each side of the disc-shaped flexible composite solid electrolyte and place it in the self-assembled test In the abras...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com