A preparation method and application of a modified metal lithium negative electrode current collector

A current collector and metal lithium technology, which is applied in the field of improving the lithium affinity of the current collector surface, can solve the problems of high cost and complicated operation, and achieve the effect of low energy consumption, simple operation, and improved affinity with lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

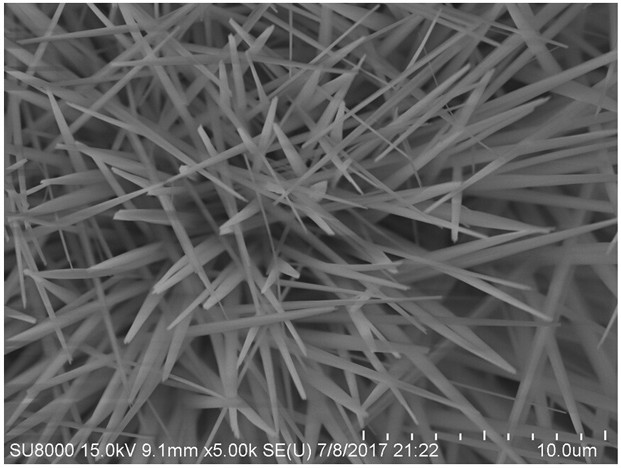

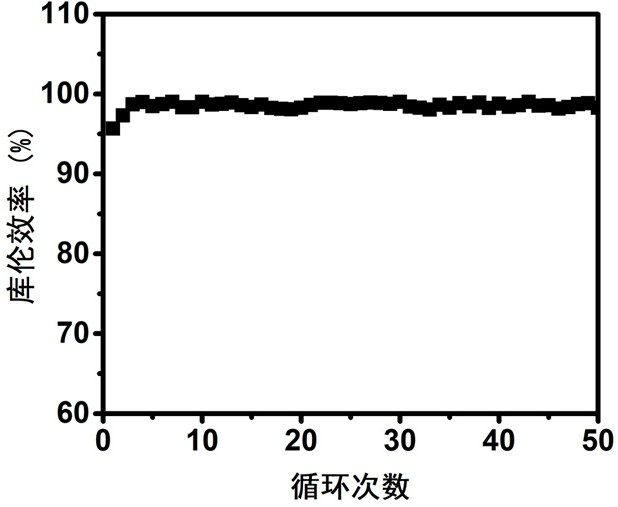

Embodiment 1

[0025] Prepare a 20% mass fraction of potassium fluoride solution. The copper foam grown with copper hydroxide nanoarrays was placed in the solution, soaked at 25 °C for 120 min, washed and dried in vacuum. The 1,3 dioxolane / ethylene glycol dimethyl ether mixed solution containing bis(trifluoromethanesulfonyl)imide lithium and lithium nitrate was used as the electrolyte, and the lithium foil was used as the counter electrode, 0.1 mA cm -2 , 0.1 mAhcm -2 Under the test conditions, the Coulombic efficiency reaches 95%.

Embodiment 2

[0027] Prepare saturated sodium fluoride solution. The copper foam grown with copper hydroxide nanoarrays was placed in the above solution, soaked at 50 °C for 30 min, washed and dried in vacuum. The 1,3 dioxolane / ethylene glycol dimethyl ether mixed solution containing bis(trifluoromethanesulfonyl)imide lithium and lithium nitrate was used as the electrolyte, and the lithium foil was used as the counter electrode, 0.1 mA cm -2 , 0.1 mAh cm -2 Under the test conditions, the Coulombic efficiency is 94%.

Embodiment 3

[0029] The copper foam grown with copper hydroxide nanoarrays was placed in 1 M potassium chloride aqueous solution, soaked at 50 °C for 30 min, washed and dried in vacuum. The 1,3 dioxolane / ethylene glycol dimethyl ether mixed solution containing bis(trifluoromethanesulfonyl)imide lithium and lithium nitrate was used as the electrolyte, and the lithium foil was used as the counter electrode, 0.1 mA cm -2 , 0.1 mAh cm -2 Under the test conditions, the Coulombic efficiency is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com