Preparation method of photocatalytic film with energy storage function

A photocatalytic film and energy storage technology, applied in the field of photocatalysis, can solve the problems of easy peeling, cracking strength and singleness of the film, and achieve the effects of benefiting photocatalytic performance, improving bonding strength and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

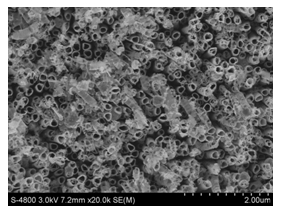

[0024] (1) Preparation of titanium dioxide nanotube array film

[0025] Mix deionized water and ethylene glycol at a mass ratio of 1:4, use the mixed solvent to prepare an ammonium fluoride solution with a concentration of 0.25%, add the ammonium fluoride solution into the reaction vessel as an electrolyte, and titanium sheets (purity 99 %) as the anode, platinum sheet (99.99% purity) as the cathode, the distance between the anode and the cathode is 2cm, anodized for 4 hours at a temperature of 40°C and a voltage of 40V, and a titanium dioxide nanotube array film is formed on the surface of the titanium sheet. After the reaction, the titanium sheet with the titanium dioxide nanotube array thin film on the surface was ultrasonically cleaned in acetone, dried, and annealed at 460° C. for 4 hours under the protection of nitrogen.

[0026] (2) Electrodeposition of cobalt

[0027] The annealed titanium sheet with a titanium dioxide nanotube array film on its surface was used as th...

Embodiment 2

[0033] Prepare titanium dioxide nanotube array thin film by the step of embodiment 1 (1), the sample after annealing is made cathode, and platinum plate is made anode, and the distance between cathode and anode is 2cm, in the 5mmol / L cobalt nitrate containing 0.04% isopropanolamine In an aqueous solution, direct current deposition at room temperature for 30 seconds at a current of 5 mA, wash the sample with deionized water and ethanol in sequence, and dry to obtain the product.

Embodiment 3

[0035] Prepare titanium dioxide nanotube array thin film by the step of embodiment 1 (1), the sample after annealing is made cathode, and platinum plate is made anode, and the distance between cathode and anode is 2cm, in the 5mmol / L chlorination that contains 0.1% isopropanolamine Cobalt aqueous solution, direct current deposition at room temperature for 30 seconds under 5mA current, washing the sample with deionized water and ethanol in sequence, and drying to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com