Chinese fir carbon sheet electrode material based on carbon nanotubes and manganese dioxide and preparation method thereof, and super capacitor

A technology of carbon nanotubes and manganese dioxide, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor conductivity and unsatisfactory long-term performance, and achieve the effect of improving stability and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

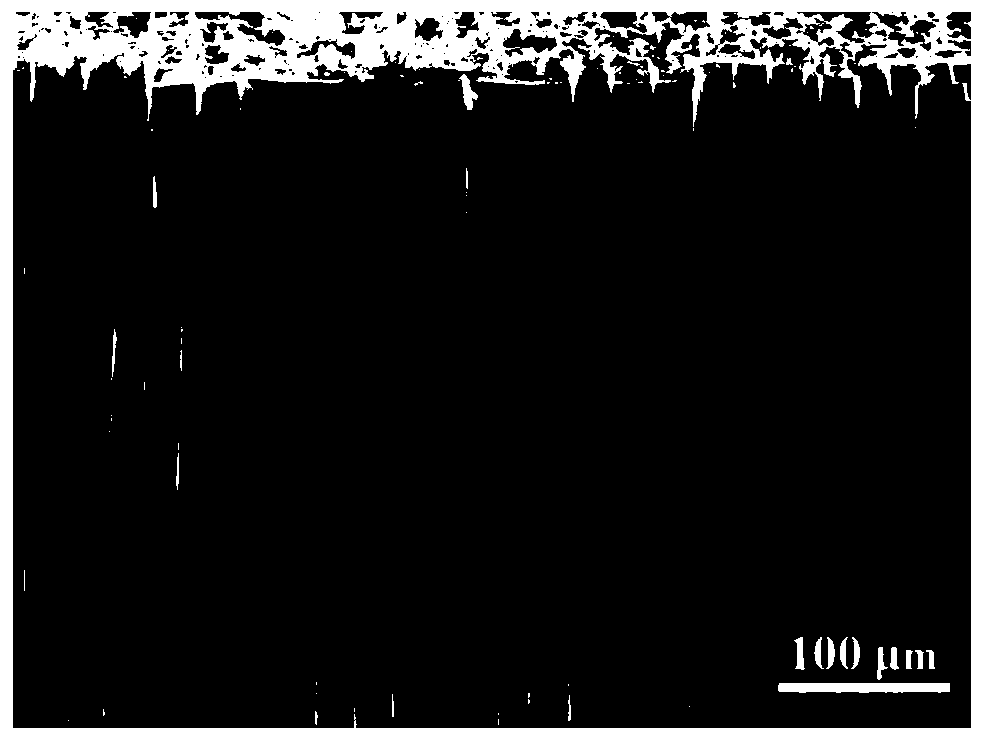

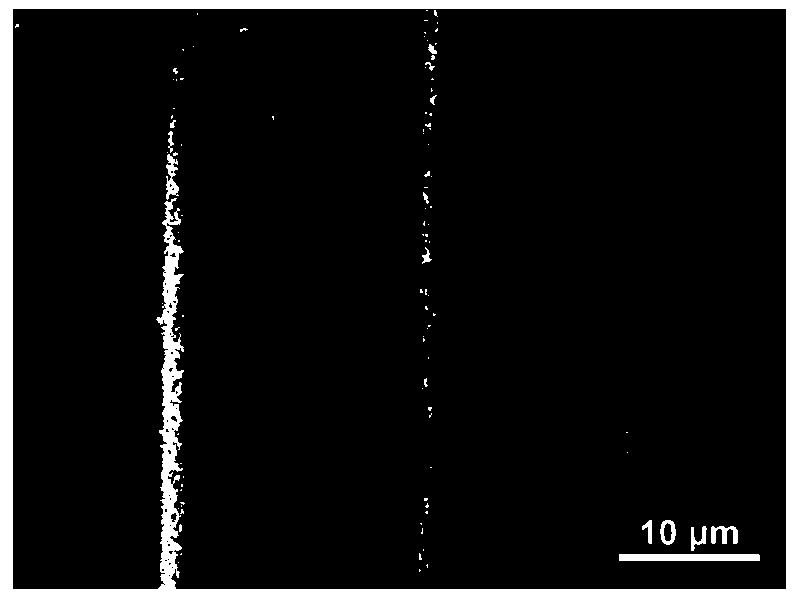

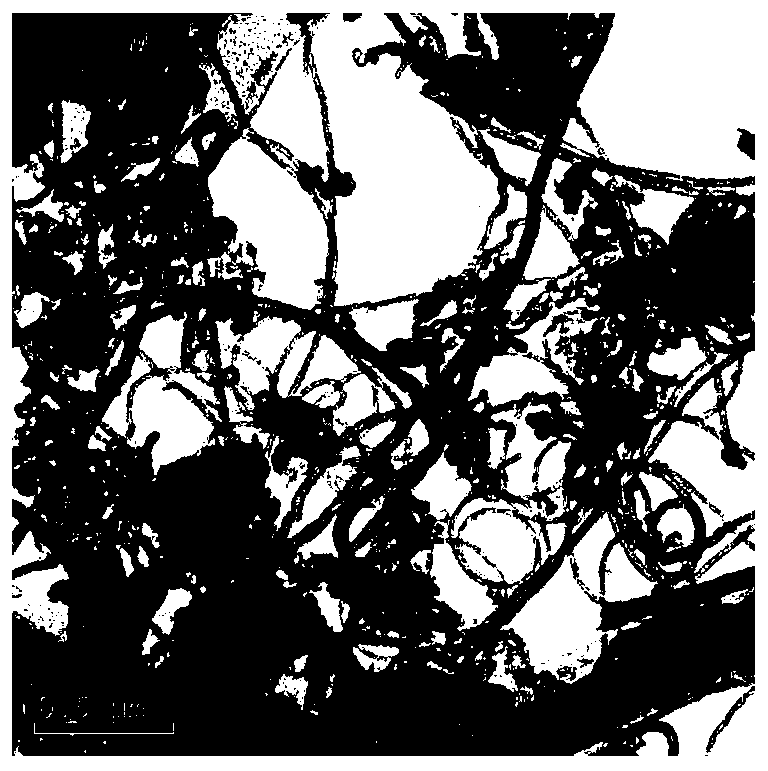

[0045] The Chinese fir carbon sheet electrode material based on carbon nanotubes and manganese dioxide is obtained by activation treatment, chemical vapor deposition and electrochemical deposition of the carbonized fir sheet; after the activation treatment, the carbonized fir sheet is A neat and straight tracheid structure from top to bottom is formed; the chemical vapor deposition includes CO 2 Chemical vapor deposition of carbon nanotubes on the sheet-like fir sheet after activation, so that carbon nanotubes grow on the inner wall of the tracheid structure; Manganese dioxide is deposited.

[0046] The preparation method of the fir carbon sheet electrode material based on carbon nanotubes and manganese dioxide of the present embodiment is,

[0047] 1) After natural air-drying, the Chinese fir wood processing residue block is cut into a thickness of 1mm.

[0048] 2) carbonization, place the Chinese fir block in step 1) in a hot air drying oven at 250°C for pre-carbonization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com