Synchronous sludge treatment system of membrane bioreactor and sludge treatment method thereof

A membrane bioreactor, sludge treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Expensive and other problems, to achieve good economic and environmental benefits, save equipment and manpower, and not easy to secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

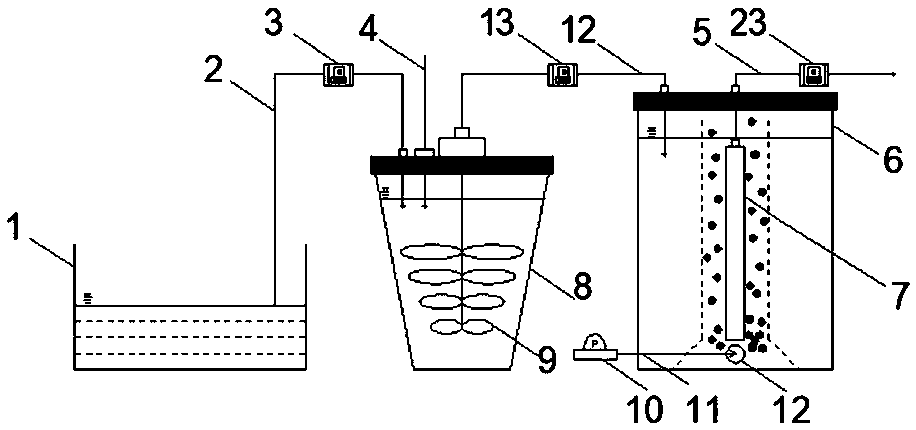

[0034] 10 L of the same sludge as the comparative example was used as the sample injection matrix (the total solid content was 21-22 g / L, and the volatile solid content was 14-15 g / L) into the pretreatment reaction tank 8 continuously, and at the same time gram of dry mud plus 0.015 gram of Fe 2+ Add ferrous sulfate heptahydrate and add 0.043 grams of S per gram of dry mud 2 o 8 2- Potassium persulfate is added, the stirring time (residence time) is set to 2 minutes, and the stirring speed is set to 300 rpm. Subsequently, the treated sludge is continuously injected into the membrane bioreactor 6 through the reactor peristaltic pump 13, and then continuously discharged from the system through the outlet peristaltic pump 23 from the outlet of the flat membrane 7 inside the reactor. Adjust the pump speed of the water outlet peristaltic pump 23 to control the water outlet flow rate at 22 mL / s / m 2 . The aeration rate was set at 5 L / min, and the aeration was continued during th...

Embodiment 2

[0036] 10 L of the same sludge as the comparative example was used as the sample injection matrix (the total solid content was 21-22 g / L, and the volatile solid content was 14-15 g / L) into the pretreatment reaction tank 8 continuously, and at the same time gram of dry mud plus 0.031 gram of Fe 2+ Add ferrous sulfate heptahydrate and add 0.086 grams of S per gram of dry mud 2 o 8 2- Potassium persulfate is added, the stirring time (residence time) is set to 2 minutes, and the stirring speed is set to 300 rpm. Subsequently, the treated sludge is continuously injected into the membrane bioreactor 6 through the reactor peristaltic pump 13, and then the water is continuously discharged from the outlet of the flat membrane 7 inside the reactor through the outlet peristaltic pump 23. Adjust the pump speed of the water outlet peristaltic pump 23 to control the water outlet flow rate at 22 mL / s / m 2 . The aeration rate was set at 5 L / min, and the aeration was continued during the r...

Embodiment 3

[0038] 10 L of the same sludge as the comparative example was used as the sample injection matrix (the total solid content was 21-22 g / L, and the volatile solid content was 14-15 g / L) into the pretreatment reaction tank 8 continuously, and at the same time gram of dry mud plus 0.046 gram of Fe 2+ Add ferrous sulfate heptahydrate and add 0.129 grams of S per gram of dry mud 2 o 8 2- Potassium persulfate is added, the stirring time (residence time) is set to 2 minutes, and the stirring speed is set to 300 rpm. Subsequently, the treated sludge is continuously injected into the membrane bioreactor 6 through the reactor peristaltic pump 13, and then the water is continuously discharged from the outlet of the flat membrane 7 inside the reactor through the outlet peristaltic pump 23. Adjust the pump speed of the water outlet peristaltic pump 23 to control the water outlet flow rate at 22 mL / s / m 2 . The aeration rate was set at 5 L / min, and the aeration was continued during the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com