Anti-impact structure optimized design method

An optimized design, impact-resistant technology, applied in clothing, helmets, helmet covers, etc., can solve problems such as increasing the overall structural mass, center of mass offset, component or human body damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to present the purpose and technical solution of the present invention more clearly, the application of this method will be further described in detail in conjunction with the design of a certain impact-resistant equipment:

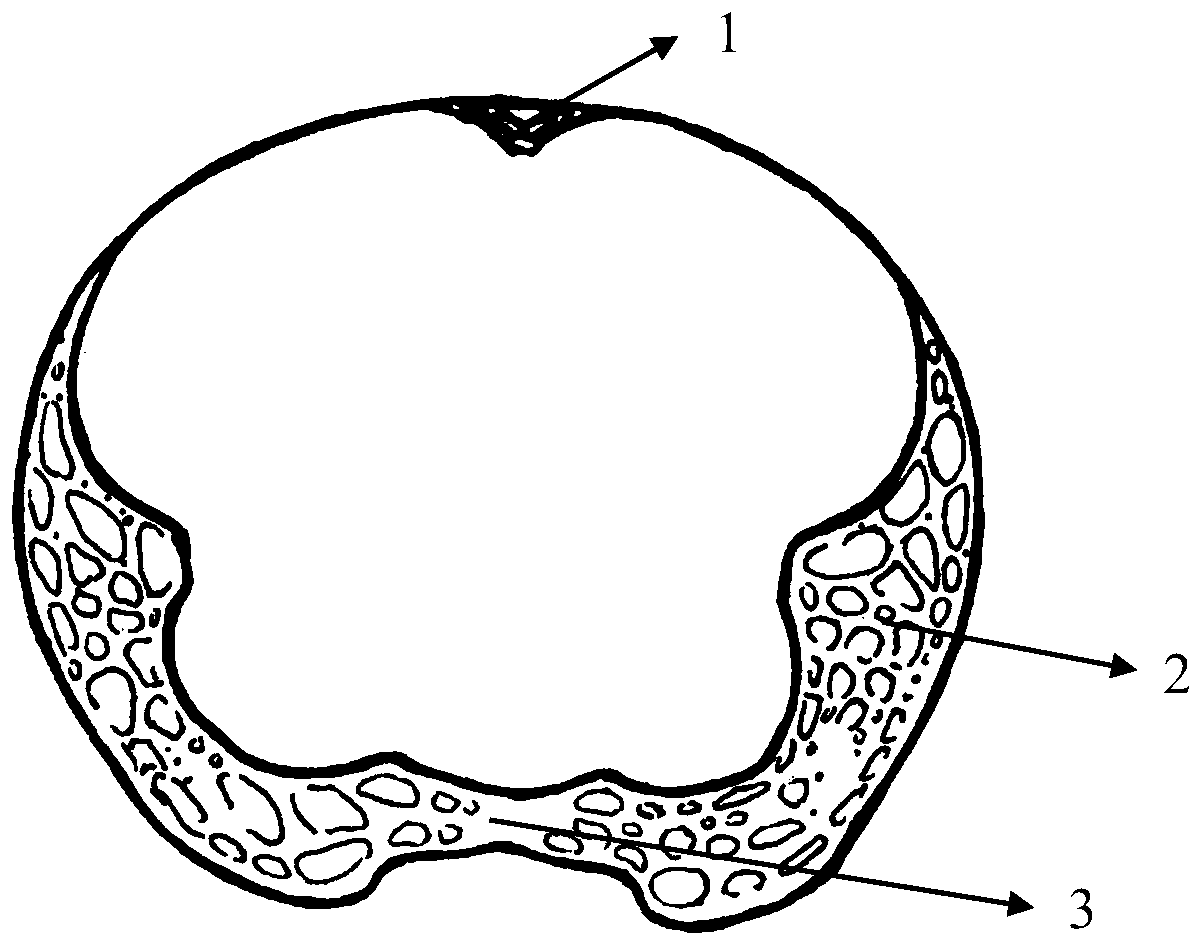

[0019] The impact resistance design of protective equipment is mainly carried out on the microscopic parameter design and distribution optimization of its internal structure; by optimizing the internal microstructural parameters and the distribution position of the structure, the overall impact resistance of the protective equipment is increased, and the The utilization rate of materials reduces the quality of equipment and improves the stability of equipment.

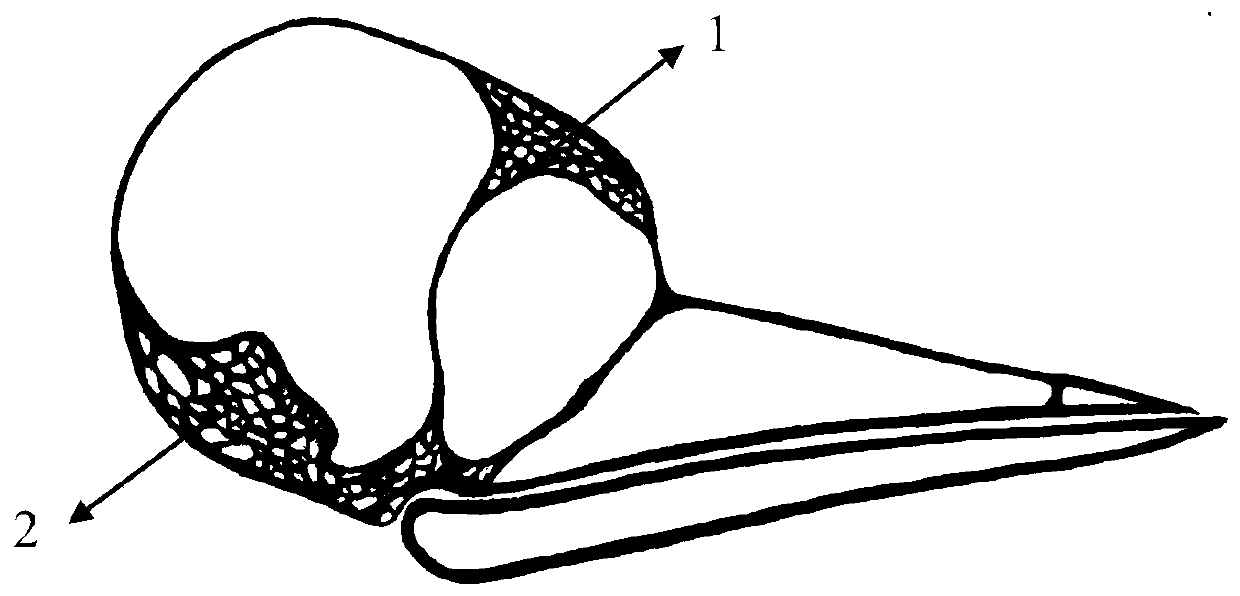

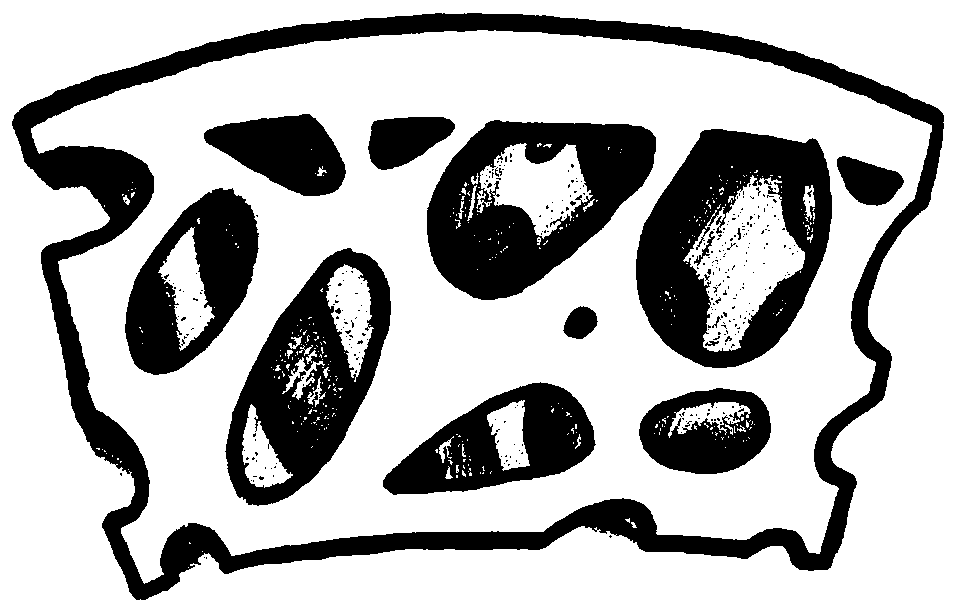

[0020] First of all, aiming at the design of the microscopic parameters of the internal structure of the protective equipment, combined with the porous morphology and microstructural characteristics of the cancellous bone in the woodpecker skull, the structural parameters such as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com