High-strength and low-extension plant cultivation carpet and preparation method thereof

A high-strength, low-stretch, planting blanket technology, applied in chemical instruments and methods, applications, non-woven fabrics, etc., can solve problems such as fixed plants, easy aging, and plant root rot, reducing waste of resources, simple production processes, and reducing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

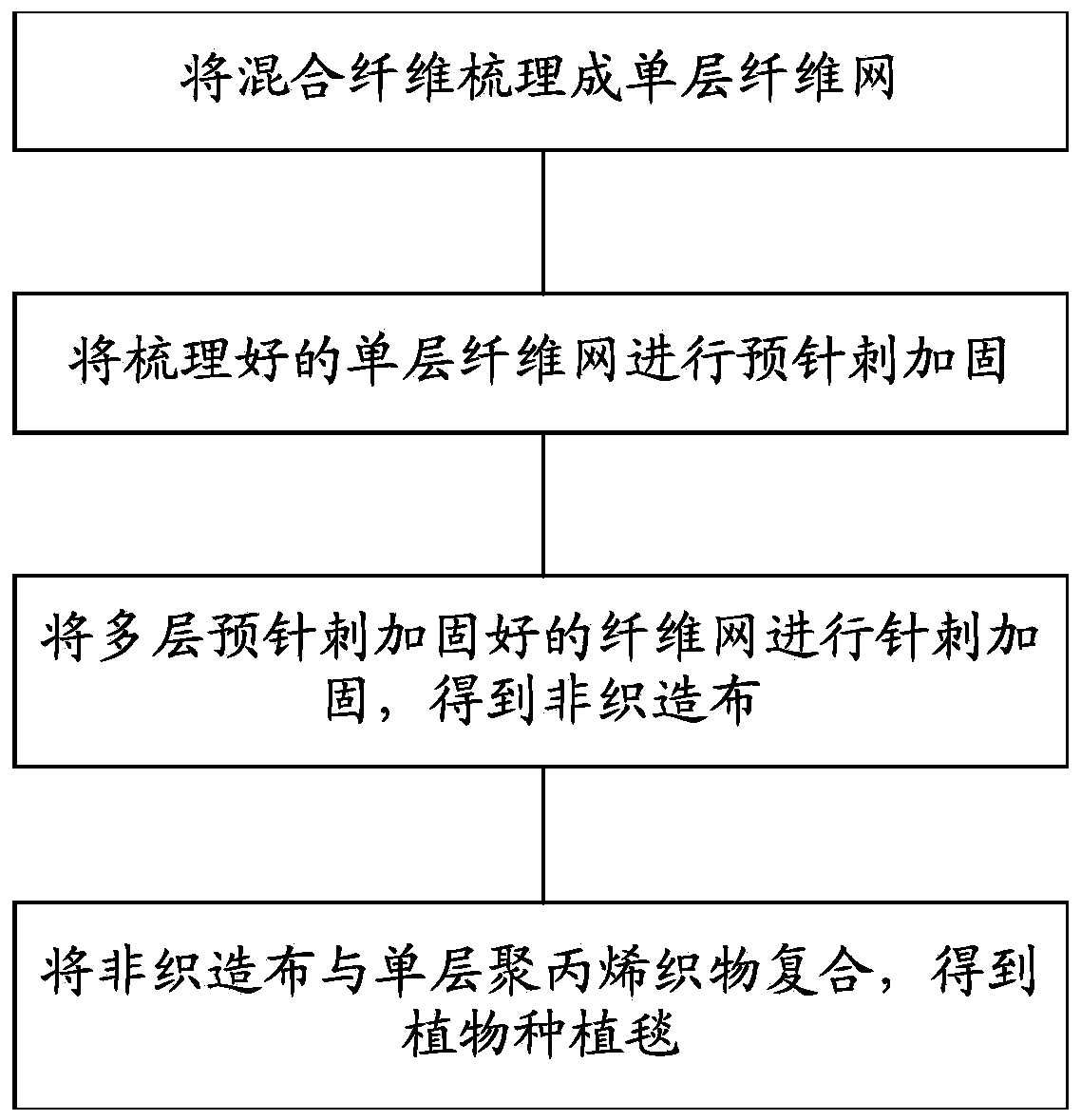

[0033] ginseng figure 1 As shown, the invention discloses a preparation method of a high-strength low-stretch plant planting blanket, comprising:

[0034] S1, carding the mixed fibers into a single-layer fiber web, and the carding is carried out in a carding machine;

[0035] S2, performing pre-acupuncture reinforcement on the combed single-layer fiber web, and the pre-acupuncture reinforcement is carried out on a pre-acupuncture machine;

[0036] S3, performing acupuncture reinforcement on the multi-layer pre-acupuncture reinforced fiber web to obtain a nonwoven fabric, and the acupuncture reinforcement is performed on the main acupuncture machine;

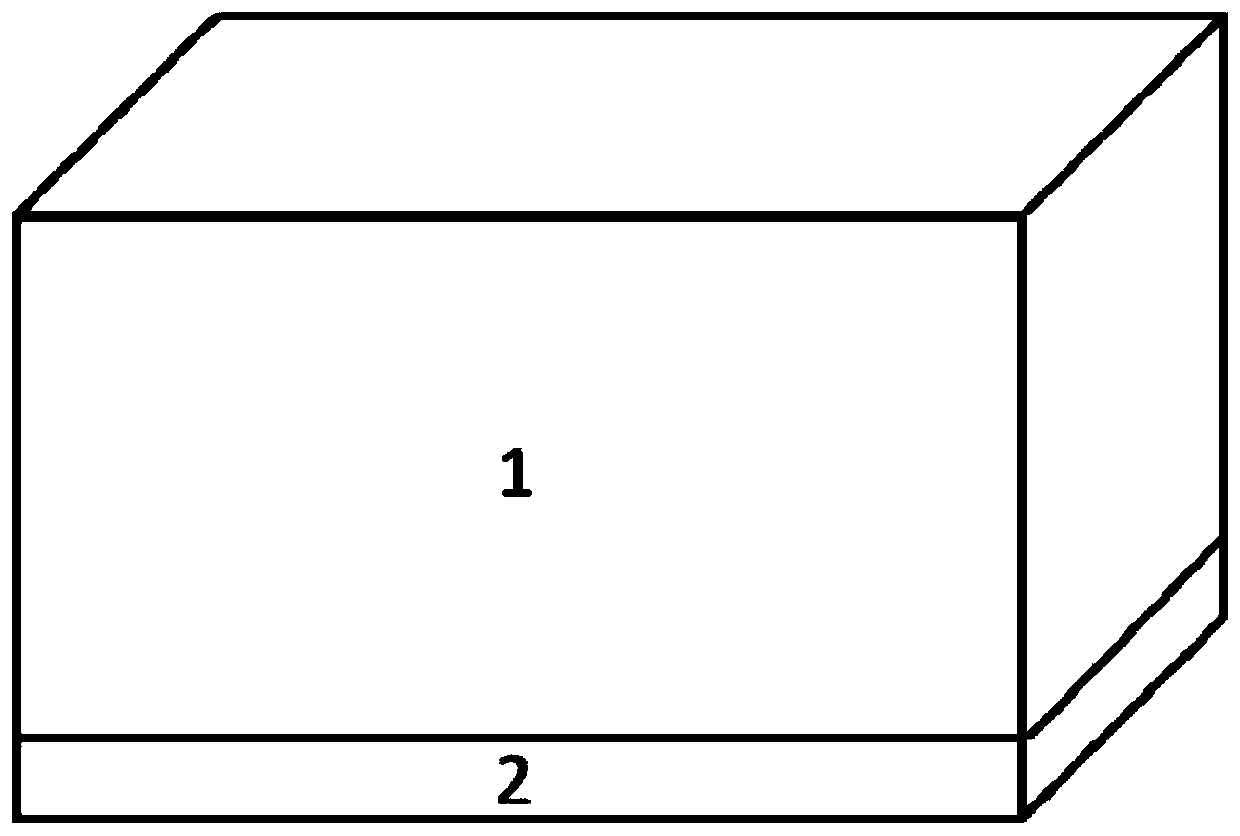

[0037] S4, composite the non-woven fabric with the single-layer polypropylene fabric to obtain figure 2 The plant planting blanket shown is composed of a nonwoven fabric (mixed fiber mesh layer) 1 and a polypropylene fabric layer 2 .

[0038] The upper layer of the planting blanket is processed by needle-punching of fiber mat...

Embodiment 1

[0047] In this embodiment, the mixed fibers are firstly carded into a web in a carding machine.

[0048] In the mixed fibers, the first fiber is polyester fiber, the second fiber is cotton fiber, the third fiber is polyacrylonitrile fiber, and the mass ratio of the first fiber, the second fiber and the third fiber is about 5:4:1.

[0049] Lay the mixed fiber web that has been carded in multiple layers, and then enter the pre-needling machine with a punching density of 50 punches / cm 2 ; Acupuncture depth is 4mm; Acupuncture frequency is 300 times / min.

[0050] Lay 2 to 6 layers of the pre-needled fiber web and then enter the main needling machine at a needling depth of 8mm; the needling density is 160 punches / cm 2 ;Acupuncture frequency of 400 times / min is reinforced into a planting blanket.

Embodiment 2

[0052] In this embodiment, the mixed fibers are firstly carded into a web in a carding machine.

[0053] In the mixed fibers, the first fiber is polyester fiber, the second fiber is cotton fiber, the third fiber is polyacrylonitrile fiber, and the mass ratio of the first fiber, the second fiber and the third fiber is about 5:4:1.

[0054] Lay the mixed fiber web that has been carded in multiple layers, and then enter the pre-needling machine with a punching density of 50 punches / cm 2 ; Acupuncture depth is 4mm; Acupuncture frequency is 300 times / min.

[0055] Lay 2 to 6 layers of the pre-needled fiber web and then enter the main needling machine at a needling depth of 8mm; the needling density is 160 punches / cm 2 ; Acupuncture frequency 400 times / min reinforcement.

[0056] Then the needle-punched fabric and the polypropylene fabric with a thickness of 2mm are needled at a depth of 8mm; the needle density is 160 punches / cm 2 ; Acupuncture frequency 400 times / min reinforceme...

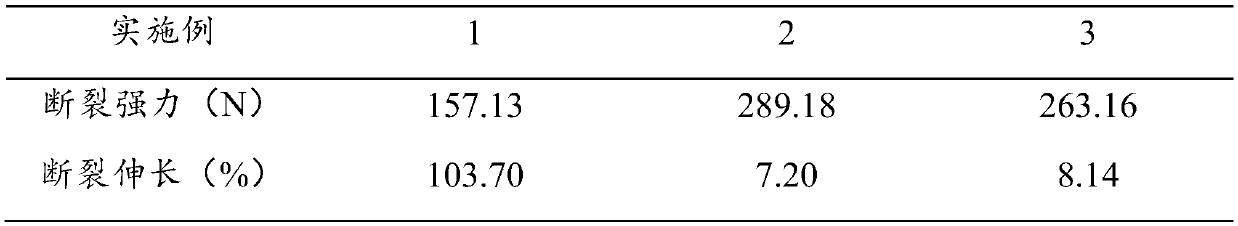

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com