Improved corrosion-resistant superaustenitic stainless steel and preparation method thereof

A kind of austenitic stainless steel, corrosion-resistant technology, applied in the field of improved corrosion-resistant super austenitic stainless steel and its preparation, can solve the problem that N08367 super austenitic stainless steel can not fully meet the actual needs, and achieve the improvement of intergranular corrosion Performance, reduction of forming tendency, effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

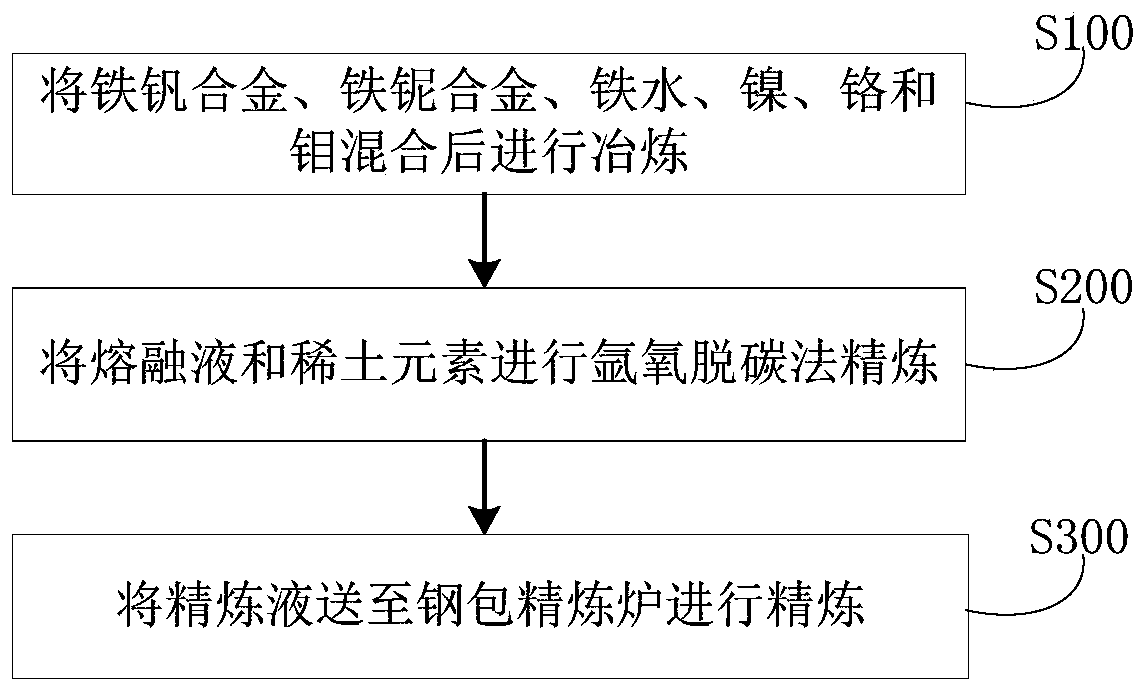

Method used

Image

Examples

Embodiment 1

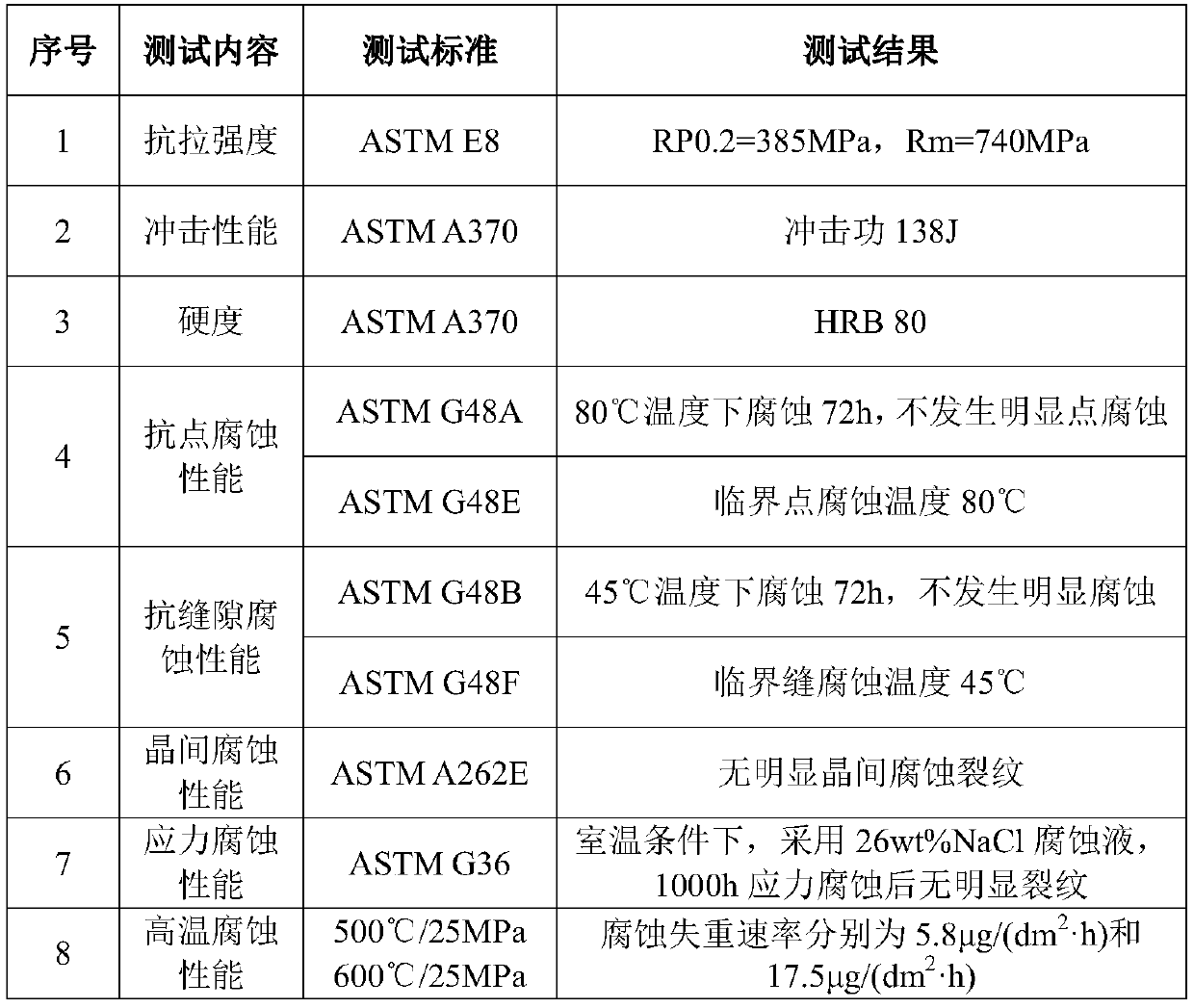

[0073] Mix the iron-vanadium alloy, iron-niobium alloy, molten iron, nickel, chromium, and molybdenum to obtain a molten liquid; refining the molten liquid and rare earth yttrium at 1550 degrees Celsius by argon-oxygen decarburization method to obtain a refined liquid; The refined liquid is sent to the ladle refining furnace for refining at 1500 degrees Celsius, so as to obtain an improved corrosion-resistant super austenitic stainless steel. The composition of the improved corrosion-resistant super austenitic stainless steel is: carbon 0.015wt%, silicon 0.43wt%, manganese 0.1wt%, phosphorus 0.015wt%, sulfur 0.001wt%, chromium 21.5wt%, nickel 24.5wt%, molybdenum 6.2wt%, vanadium 2.8wt%, niobium 2.5wt%, nitrogen 0.24wt%, rare earth yttrium 0.05wt% and the balance iron. The performance tests and results are shown in Table 1:

[0074] Table 1 Various performance tests and results of stainless steel in Example 1

[0075]

Embodiment 2

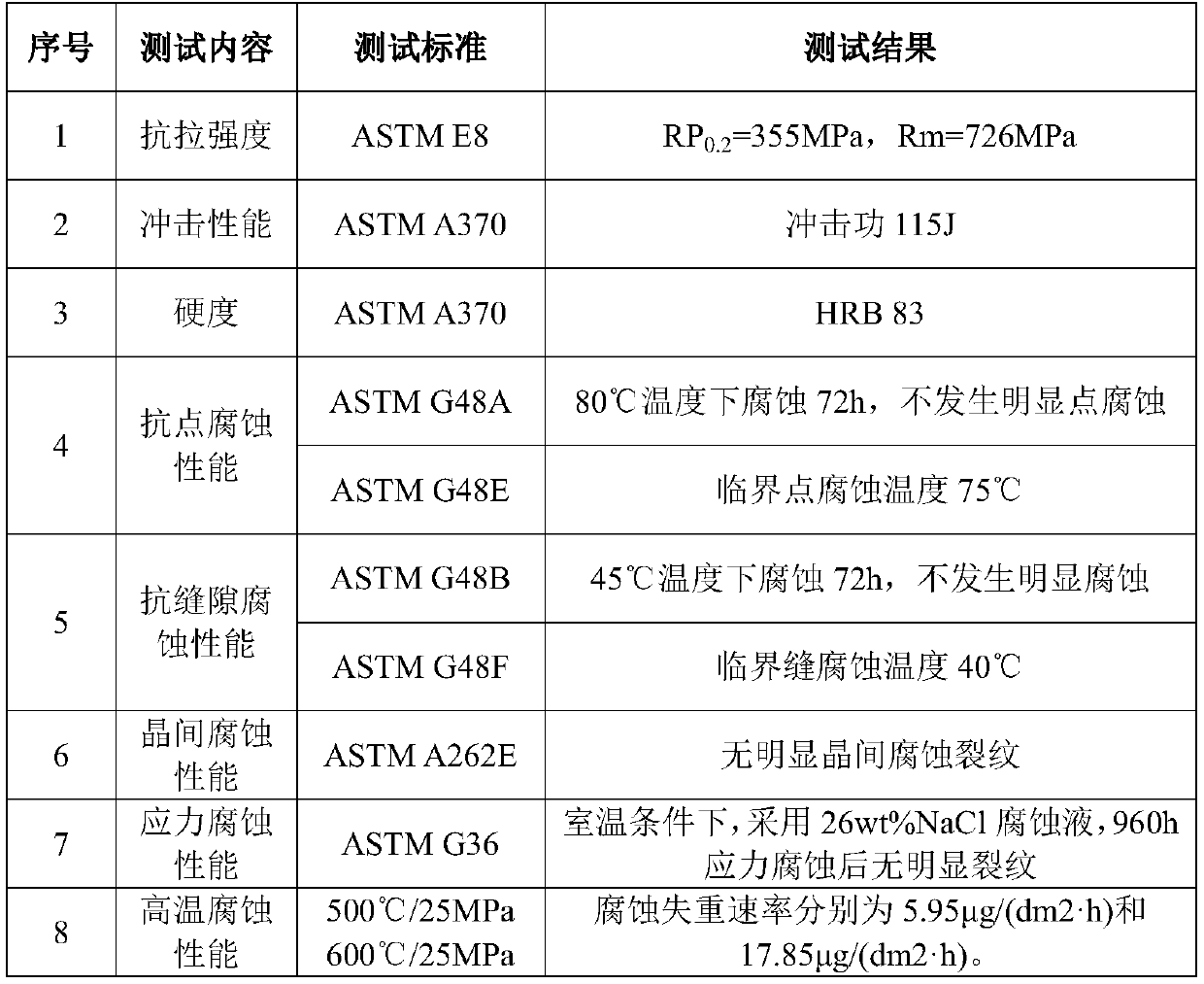

[0077] Mix the iron-vanadium alloy, iron-niobium alloy, molten iron, nickel, chromium, and molybdenum to obtain a molten liquid; refining the molten liquid and rare earth lanthanum by argon-oxygen decarburization at 1620 degrees Celsius to obtain a refined liquid; The refined liquid is sent to the ladle refining furnace for refining at 1520 degrees Celsius, so as to obtain an improved corrosion-resistant super austenitic stainless steel. The improved corrosion-resistant super austenitic stainless steel consists of 0.014wt% carbon, 0.42wt% silicon, 0.15wt% manganese, 0.015wt% phosphorus, 0.001wt% sulfur, 21.2wt% chromium, 24.2wt% nickel, molybdenum 6.0wt%, vanadium 2.5wt%, niobium 2.5wt%, nitrogen 0.22wt%, lanthanum 0.03wt% and the balance iron. The various performance tests and results are shown in Table 2:

[0078] Table 2 Example 2 stainless steel performance test and results

[0079]

Embodiment 3

[0081] Mix the ferro-vanadium alloy, molten iron, nickel, chromium and molybdenum and then smelt to obtain a molten liquid; perform argon-oxygen decarburization refining at 1640 degrees Celsius to obtain a refined liquid; send the refined liquid to a ladle refining furnace Refining at 1540 degrees Celsius to obtain improved corrosion-resistant super austenitic stainless steel. The composition of the improved corrosion-resistant super austenitic stainless steel is: carbon 0.012wt%, silicon 0.46wt%, manganese 0.18wt%, phosphorus 0.011wt%, sulfur 0.001wt%, chromium 22wt%, nickel 25.0wt%, molybdenum 6.3 wt%, vanadium 2.5wt%, nitrogen 0.20wt% and the balance iron. The various performance tests and results are shown in Table 3:

[0082] Table 3 Various performance tests and results of stainless steel in Example 3

[0083]

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com