Food-grade urushiol-based tung oil composite coating and preparation method thereof

A composite coating, food-grade technology, used in anti-corrosion coatings, natural resin coatings, anti-fouling/underwater coatings, etc., can solve the problems that the antibacterial properties are difficult to meet the requirements of use, the solvent resistance of urushiol coatings is poor, and achieve excellent Physical and mechanical properties, the effect of improving physical and mechanical properties, and improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

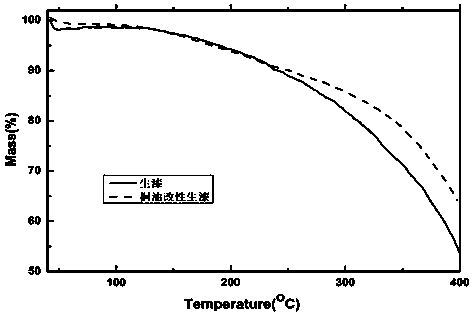

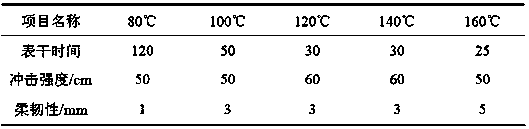

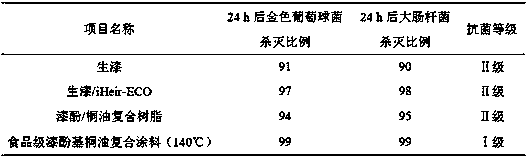

[0019] Urushiol and tung oil are mixed in a mass ratio of 7:3, and 1% of the antibacterial agent iHeir-ECO (nano titanium dioxide silver exchange body) and 1% of the antifungal agent S-1206 (2-methyl-4 -isothiazolin-3-one) and 3% drier ferrocene, mechanically stirred and mixed at room temperature for 1 hour to obtain food-grade urushiol-based tung oil composite resin.

[0020] The performance test is as follows: the film-forming performance of the coating is determined according to the GB / T1728-1979 paint film and putty film drying time test method; the impact resistance of the coating is measured according to the GB / T1732-1993 paint film impact resistance test method; Determination of GB / T1731-1993 paint film flexibility test method; coating antibacterial performance according to GBT 21866-2008 antibacterial paint (paint film) antibacterial test method and antibacterial effect test; coating antifungal performance according to GB-T 1741-2007 paint Determination of film mold re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com