Porous aerogel based on bionic vascular bundle microstructure and preparation method and application thereof

A technology of porous airgel and microstructure, which is applied in the direction of airgel preparation, separation methods, chemical instruments and methods, etc., can solve the problems of uncontrollable adsorption and mechanical extrusion resistance, and achieve low production cost and low raw material Accessible, highly controllable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

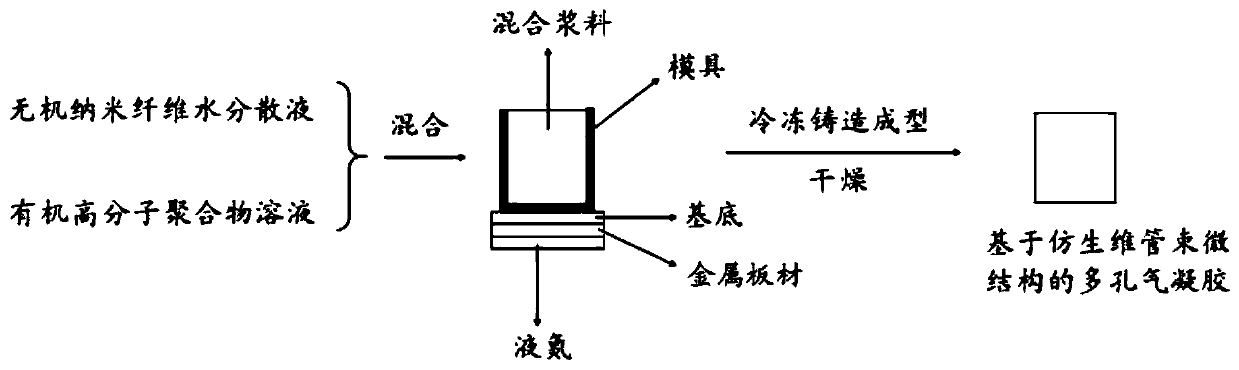

[0028] The invention provides a method for preparing a porous airgel based on a bionic vascular bundle microstructure, comprising the following steps:

[0029] Mixing inorganic nanofibers, organic polymers and solvents to obtain a mixed slurry;

[0030] The mixed slurry is placed in a mold, the mold containing the mixed slurry is placed on the base, and then freeze casting is performed to obtain a porous airgel based on the bionic vascular bundle microstructure.

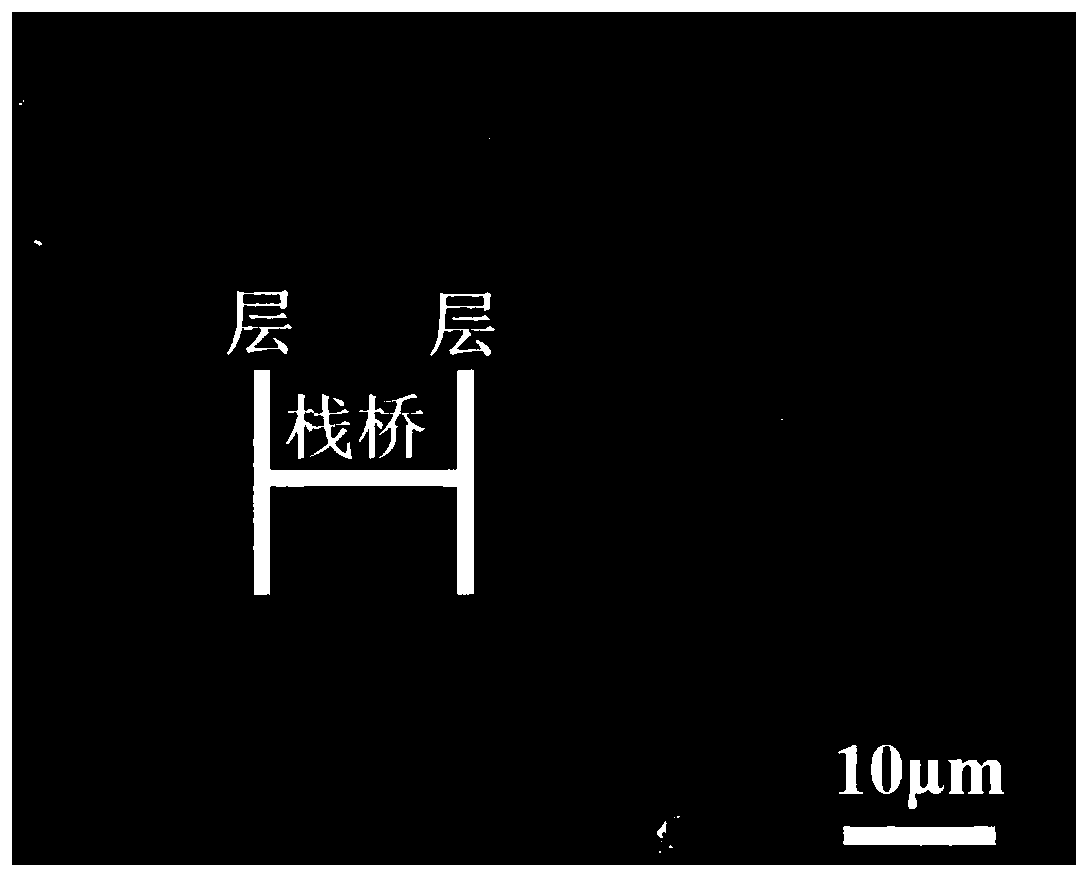

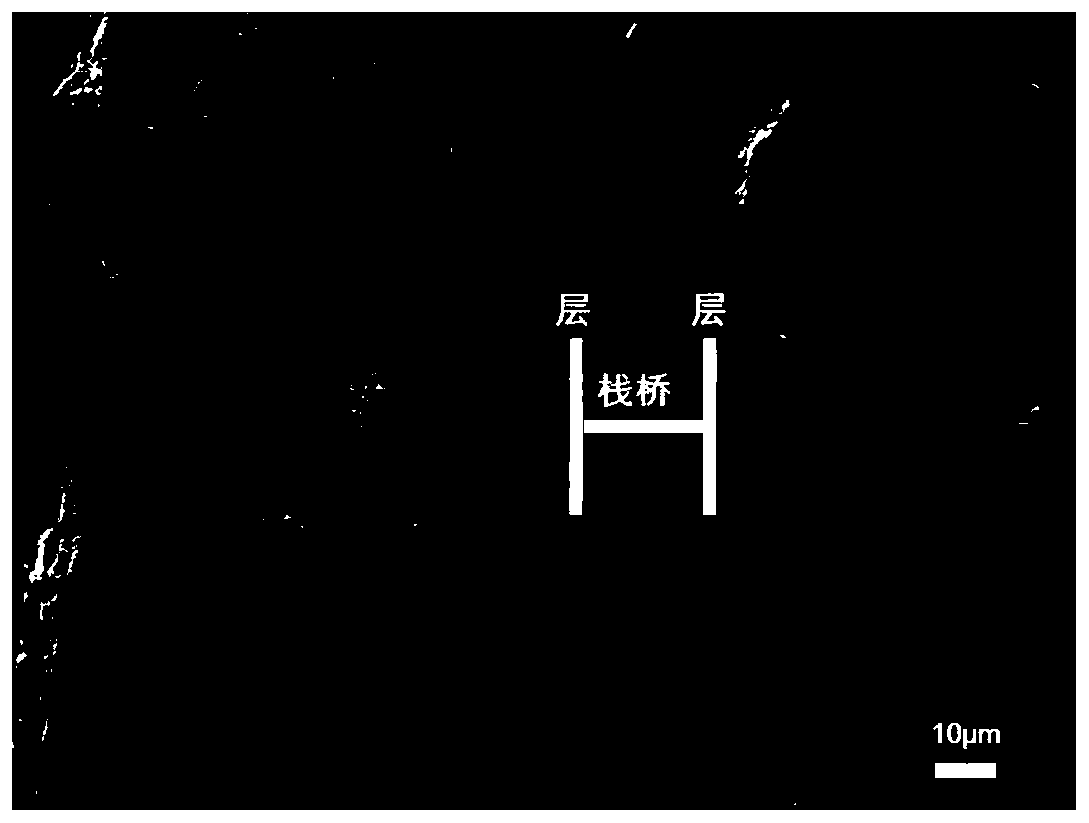

[0031] In the present invention, inorganic nanofibers and organic macromolecular polymers are prepared into porous aerogels by freeze casting molding method, which has a "layer-frame-layer" structure assembled from fiber scaffolds and compatible embedding layers ( Wherein, the fiber scaffold is formed by inorganic nanofibers, and the compatible embedding layer is formed by organic polymers), and the "layer-frame-layer" structure is an ordered three-dimensional porous network structure, including dimensional The bion...

Embodiment 1

[0049] Preparation of copper nanowire-sodium alginate porous airgel based on biomimetic vascular bundle microstructure, such as figure 1 shown, including the following steps:

[0050] Weigh 0.49g of sodium alginate (weight-average molecular weight of 15000, degree of polymerization of 5000) solid particles in a 30mL beaker, add 10mL of N,N-dimethylformamide to it, then add 10mL of deionized water, at 500rpm Under mechanical stirring for 12 hours, a uniform sodium alginate solution was obtained;

[0051] Take 5mL of the copper nanowire aqueous dispersion with a concentration of 45mg / mL (wherein, the diameter of the copper nanowire is 20nm and the length is 100 μm), and another 7.5mL of the above-mentioned sodium alginate solution is slowly added to the copper nanowire aqueous dispersion, Under the condition of 300rpm rotating speed, magnetically stir for 8h to obtain the mixed slurry;

[0052] Place a polydimethylsiloxane base (0.01cm in thickness) on a clean copper plate (0....

Embodiment 2

[0054] The preparation of the silver nanowire-sodium alginate porous airgel based on the bionic vascular bundle microstructure comprises the following steps:

[0055] Weigh 1.4g of sodium alginate (weight-average molecular weight: 25,000, polymerization degree: 10,000) solid particles in a 30mL beaker, add 10mL of N,N-dimethylformamide to it, then add 10mL of deionized water, at 500rpm Under mechanical stirring for 12 hours, a uniform sodium alginate solution was obtained;

[0056] Get 5mL concentration and be the silver nanowire aqueous dispersion of 11mg / mL (wherein, the diameter of silver nanowire is 30nm, length is 100 μ m), get another 5mL above-mentioned sodium alginate solution and slowly add in the silver nanowire aqueous dispersion, in Under the condition of 300rpm rotating speed, magnetically stir for 8h to obtain the mixed slurry;

[0057] Place a polydimethylsiloxane base (0.01cm in thickness) on a clean copper plate (0.5cm in thickness), and then place a mold (ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com