Toothpaste core material and crispy soft-core solid toothpaste prepared from toothpaste core material

A technology of solid toothpaste and core material, applied in the directions of dentistry, cosmetic preparations, dressing preparations, etc., can solve the problems of stickiness, not easy to absorb moisture and deteriorate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A solid toothpaste is formed by wrapping a toothpaste core material with a sugar coating;

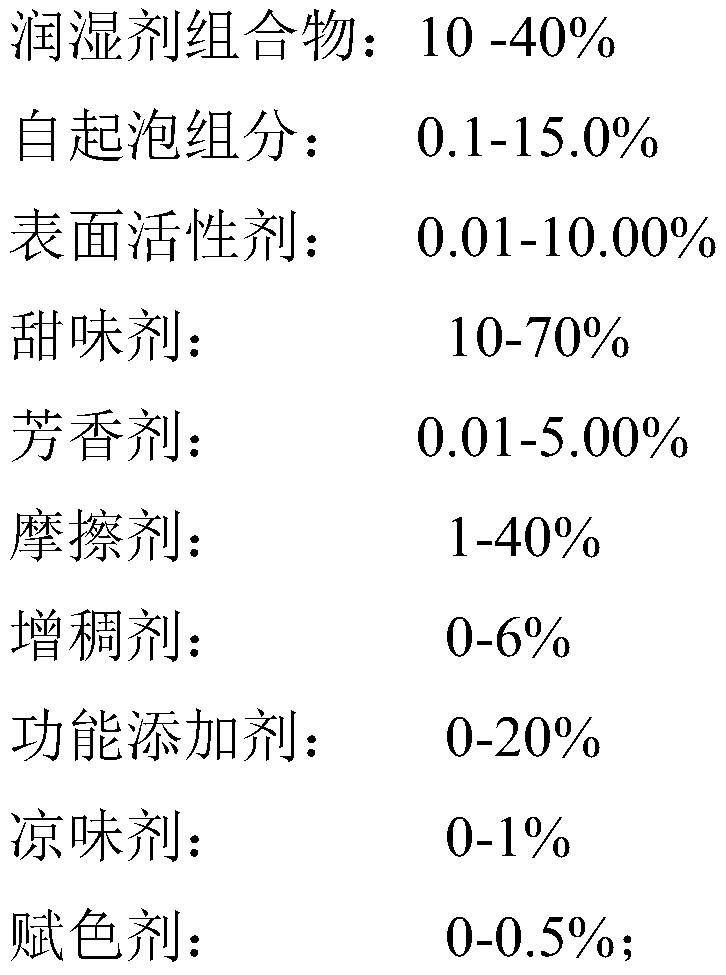

[0063] Described toothpaste core material is made up of the composition of following mass percentage:

[0064]

[0065]

[0066] Wetting agent part

[0067]

[0068] The sum of the wetting agent fractions is 21%. The mass ratio of liquid and solid (at room temperature 20°C) wetting agent is 1:20 (ie 0.05:1).

[0069] The preparation method of the core material comprises the following steps: dispersing carrageenan in propylene glycol, dissolving essence, menthyl lactate and sucralose in propylene glycol and glycerin, melting polyethylene glycol and adding it to the propylene glycol dispersion in the previous step for stirring. Then add xylitol and isomalt, stir for about 10 minutes, then add sodium bicarbonate, calcium hydrogen phosphate, calcium carbonate, cellulose gel, surfactants and continue to stir for 20 minutes, stand still for about 2 hours, then use The core ...

Embodiment 2

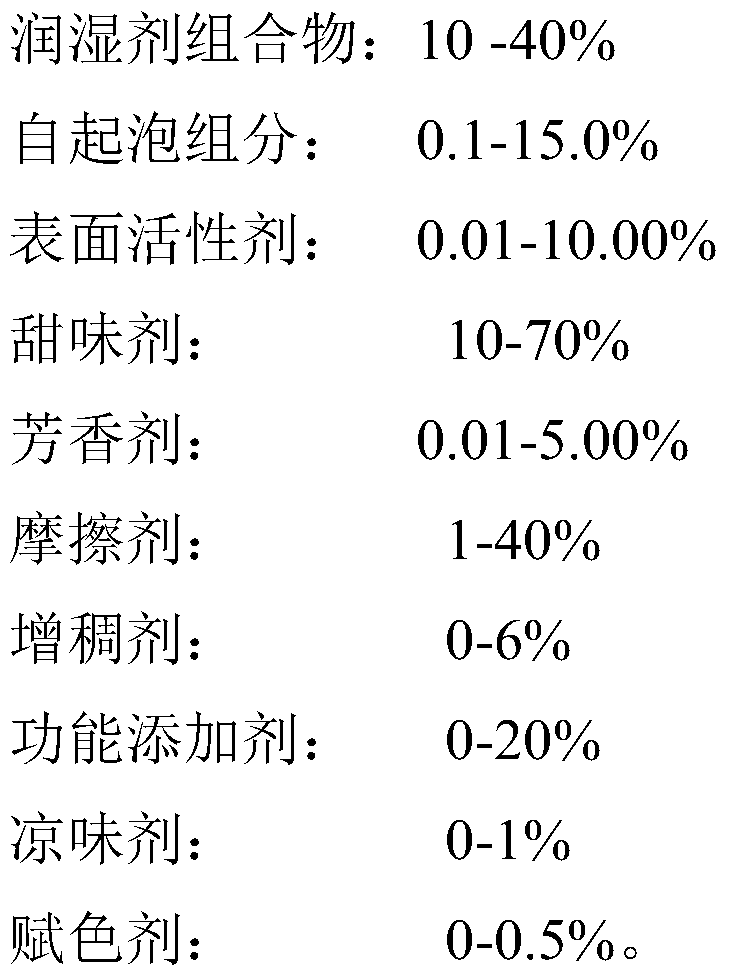

[0087] A solid toothpaste is formed by wrapping a toothpaste core material with a sugar coating;

[0088] Described toothpaste core material is made up of the composition of following mass percentage:

[0089]

[0090]

[0091] Wetting agent part:

[0092]

[0093] For the wetting agent part, the ratio of liquid to solid is 10:1 at a room temperature of 20 degrees Celsius.

[0094] The production steps of the core material are the same as in Example 1: the essence, sucralose, and carrageenan are dissolved and dispersed in a mixture of propylene glycol and polyethylene glycol to form a liquid phase, and then xylitol and isomalt are stirred in the liquid phase for about After 10 minutes, sequentially add sodium bicarbonate, calcium hydrogen phosphate, surfactant, calcium carbonate, cellulose gel and dextranase and continue to stir for 15-20 minutes, then stand still for about 1-4 hours, and then use a plodder And the pill making machine extrudes the core material to m...

Embodiment 3

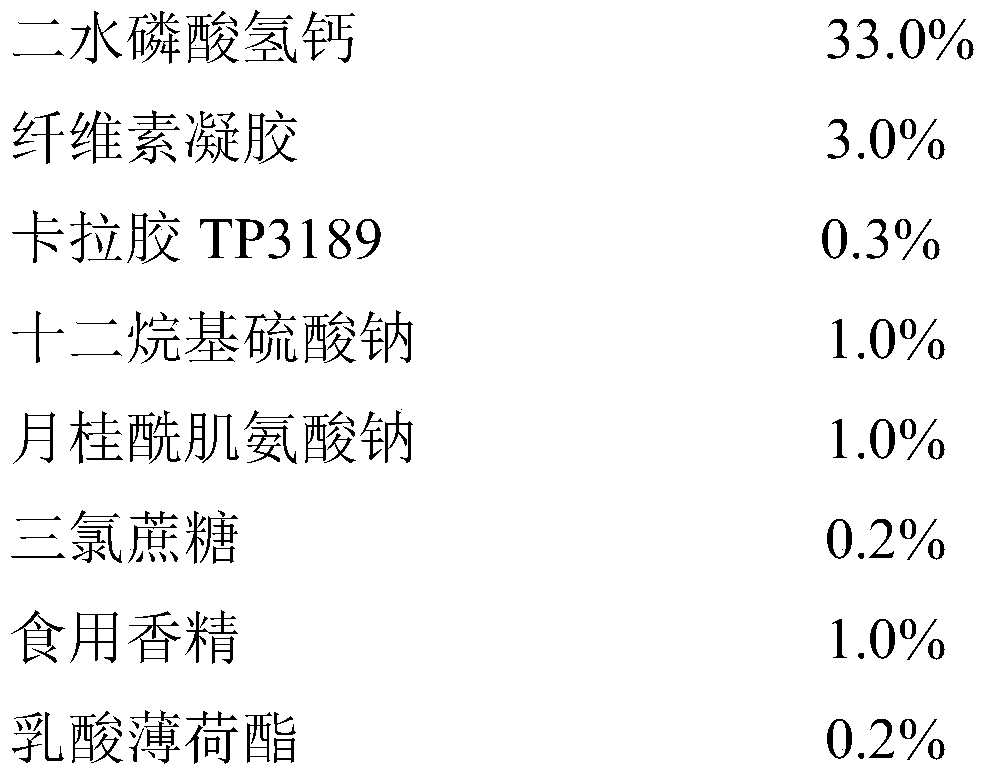

[0101] A solid toothpaste is formed by wrapping a toothpaste core material with a sugar coating;

[0102] Described toothpaste core material is made up of the composition of following mass percentage:

[0103]

[0104]

[0105] Wetting agent part:

[0106]

[0107] The mass ratio of liquid and solid (at room temperature 20°C) wetting agent is 0.7:1.0.

[0108] The production steps of the core material are the same as in Example 1: the essence (menthyl lactate is dissolved in the essence in advance), sucralose, and carrageenan are dissolved and dispersed in a mixture of propylene glycol / PEG-400 and molten polyethylene glycol to form a liquid phase, then xylitol and isomalt were stirred in the liquid phase for about 10 minutes, then sodium bicarbonate, silicon dioxide, cellulose gel, surfactant, calcium carbonate, sodium fluoride, cellulose gel were added in sequence After continuing to stir for 15-20 minutes, stand still for about 1-4 hours, and then extrude the core m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com