Polyether sulfur ether-based polymer electrolyte and preparation method thereof

A sulfide-based, polymer technology, applied in the field of lithium-ion battery electrolyte materials, can solve the problems of low room temperature ion conductivity, poor mechanical properties, poor mechanical properties, etc., to achieve improved ion conductivity, good mechanical properties, and electrical The effect of chemical window stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

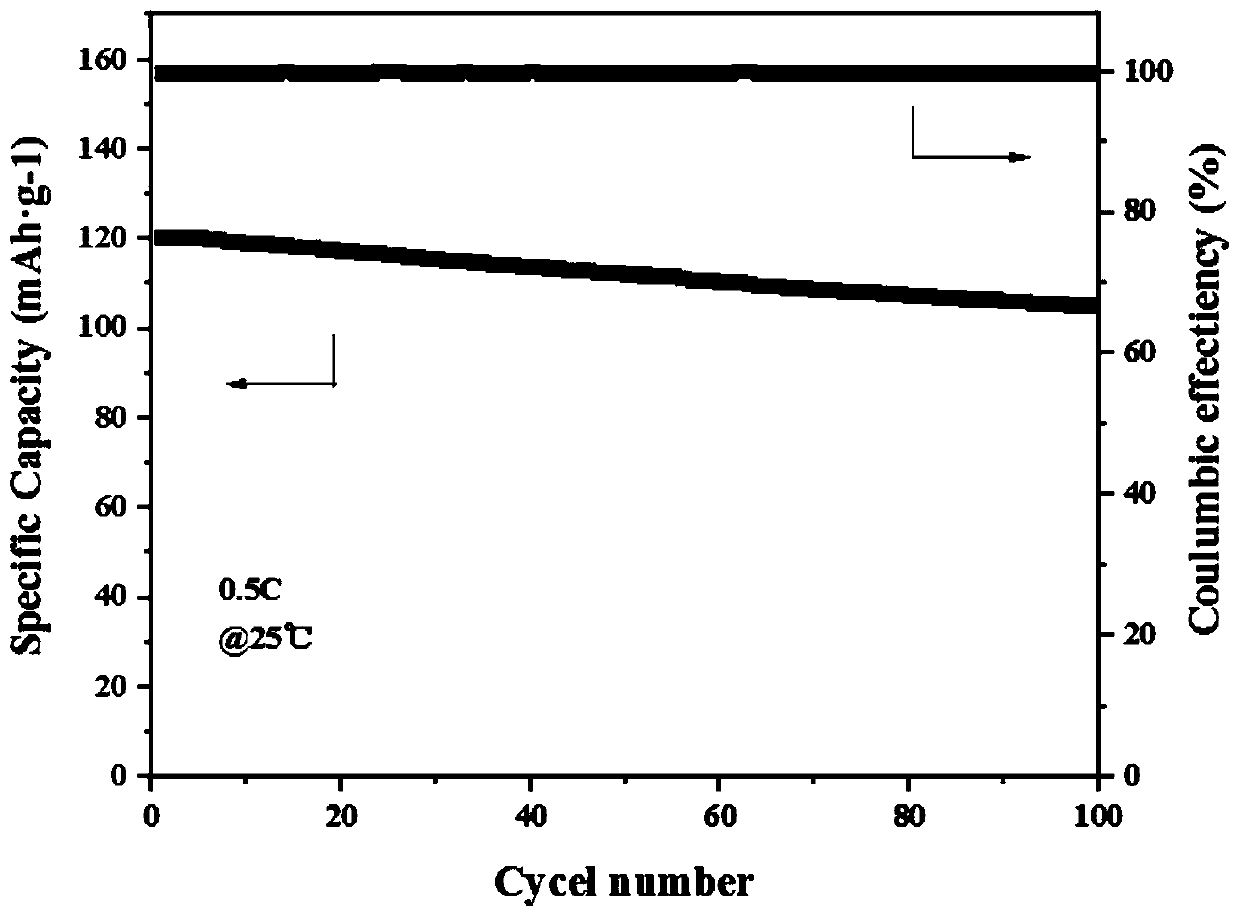

Examples

Embodiment 1

[0026] In the glove box, weigh 1,2-ethanedithiol (0.404g, mercapto group content 8.55mmol), diethylene glycol divinyl ether (0.719g, double bond content 9mmol), tetrakis(3-mercaptopropionic acid ) Pentaerythritol (0.058g, mercapto group content 0.45mmol) and other three reaction raw materials in a 10mL small glass bottle, mix well, add 0.659g lithium bis(trifluoromethyl)sulfonimide, stir after mixing, so that the lithium salt is completely Dissolve evenly, then add 0.024g benzoin dimethyl ether, stir well to obtain polyether sulfide-based polymer electrolyte prepolymer mixed solution

[0027] Pour the prepolymer mixed solution into a smooth and flat polytetrafluoro round mold, shake the mold gently so that the prepolymer mixed solution slowly covers the bottom of the mold, let it stand for 1 minute, and then irradiate with ultraviolet light for 3 minutes. Under the action of a photoinitiator, the mercapto-ene click reaction is carried out, and the film is solidified to obtain ...

Embodiment 2

[0029] In the glove box, weigh 1,2-ethanedithiol (0.383g, mercapto group content 8.1mmol), diethylene glycol divinyl ether (0.719g, double bond content 9mmol), tetrakis (3-mercaptopropionic acid ) Pentaerythritol (0.116g, mercapto group content 0.9mmol) and other three reaction raw materials in a 10mL small glass bottle, mix well, add 0.672g lithium bis(trifluoromethyl)sulfonimide, stir after mixing, so that the lithium salt is completely Dissolve evenly, then add 0.024g benzoin dimethyl ether, stir well to obtain polyether sulfide-based polymer electrolyte prepolymer mixed solution

[0030] Pour the prepolymer mixed solution into a smooth and flat polytetrafluoro round mold, shake the mold gently so that the prepolymer mixed solution slowly covers the bottom of the mold, let it stand for 1 minute, and then irradiate with ultraviolet light for 3 minutes. Under the action of a photoinitiator, the mercapto-ene click reaction is carried out, and the film is solidified to obtain a...

Embodiment 3

[0032] In the glove box, weigh 1,2-ethanedithiol (0.340g, mercapto group content 7.2mmol), diethylene glycol divinyl ether (0.719g, double bond content 9mmol), tetrakis (3-mercaptopropionic acid ) pentaerythritol (0.232g, mercapto group content 1.8mmol) and other three reaction raw materials in a 10mL small glass bottle, mix well, add 0.698g lithium bis(trifluoromethyl)sulfonimide, stir after mixing, so that the lithium salt is completely Dissolve evenly, then add 0.026g benzoin dimethyl ether, stir well to obtain polyether sulfide-based polymer electrolyte prepolymer mixed solution

[0033] Pour the prepolymer mixed solution into a smooth and flat polytetrafluoro round mold, shake the mold gently so that the prepolymer mixed solution slowly covers the bottom of the mold, let it stand for 1 minute, and then irradiate with ultraviolet light for 3 minutes. Under the action of a photoinitiator, the mercapto-ene click reaction is carried out, and the film is solidified to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com