Metal-carbon composite negative electrode material as well as preparation method and application thereof

A negative electrode material and metal technology, applied in the field of high-capacity lithium-ion battery negative electrode material and its preparation, can solve the problems of expensive raw materials, unsuitable production and application, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

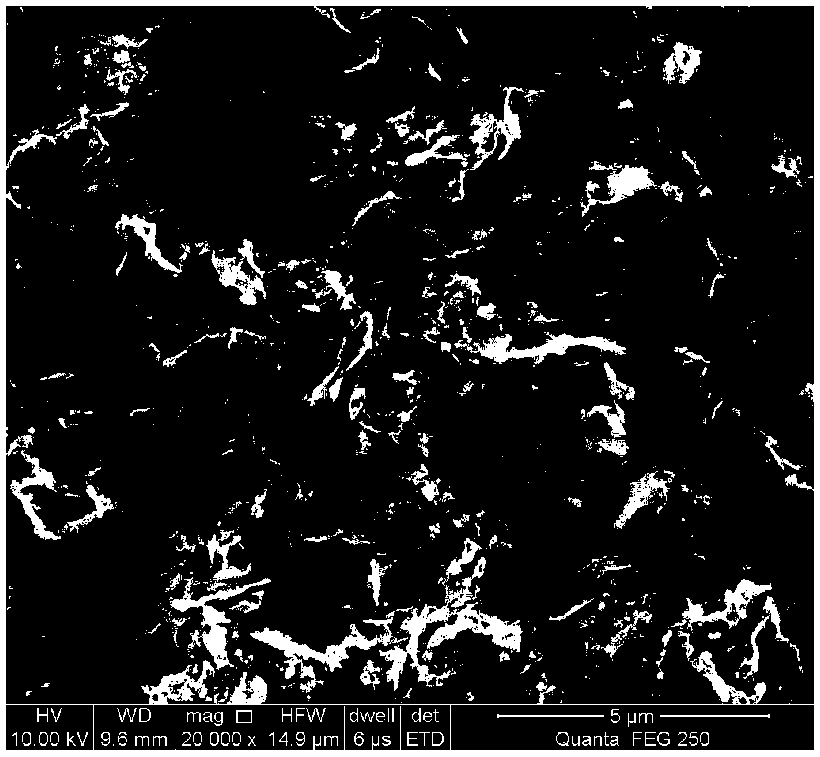

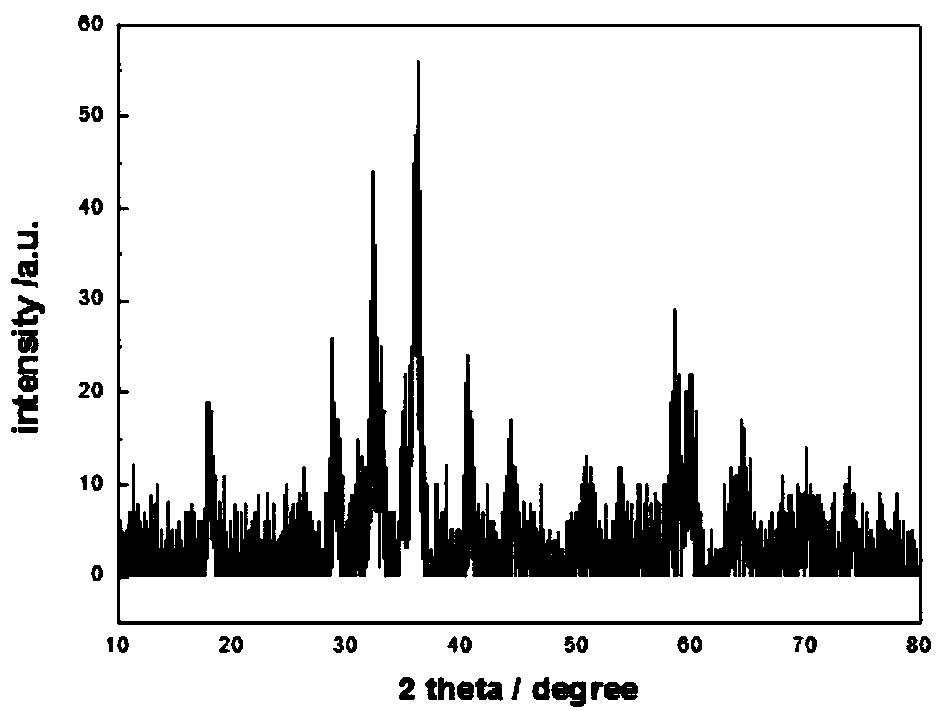

Image

Examples

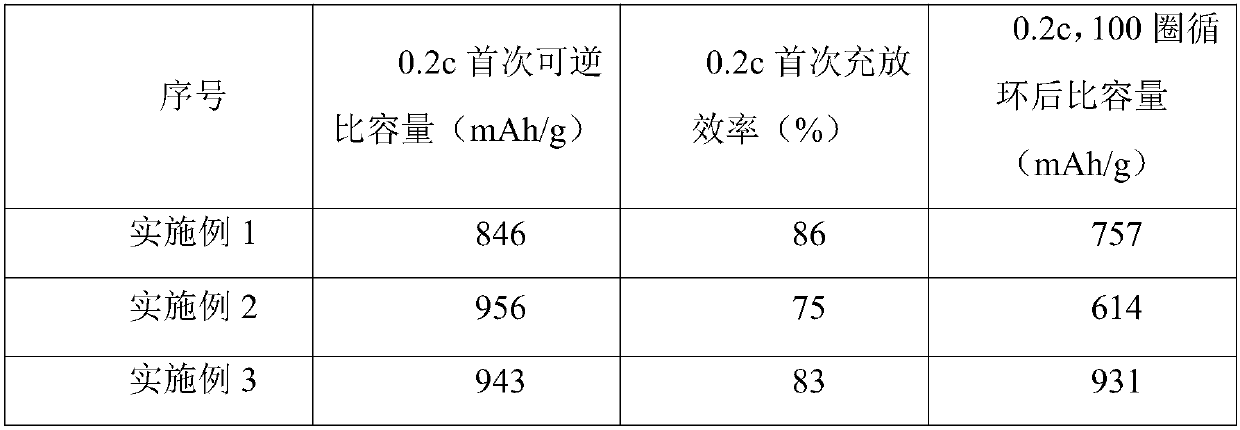

Embodiment 1

[0076] (1) Select coking coal with ash-free base volatile content of 15%, cohesive index of 52%, maximum thickness of colloidal layer of 25%, contained heteroatoms N, S, P and heteroatom content of 4% as raw material 100g of coking coal raw material dried at 120°C for 10h was put into a vibratory pulverizer for crushing for 1min, then ball milled for 6 hours in a planetary ball mill, sieved with a 500-mesh sieve, and the undersize was taken.

[0077] (2) Add 50 g of dried, crushed and sieved coking coal into a mixed acid solution with a mass ratio of hydrofluoric acid and sulfuric acid of 10:1, the liquid-solid ratio is 4, and the total acid concentration is adjusted to a pH value of 3 at room temperature. The mixture was stirred and reacted for 2 hours, filtered and washed until neutral to obtain acid-purified coke, and the ash content of the purified coke was 0.37%.

[0078] (3) Dissolve 10g of manganese acetate in 100ml of aqueous solution, add 20g of purified coke for ultr...

Embodiment 2

[0081] (1) Select coking coal with ash-free base volatile content of 25%, cohesive index of 62%, maximum thickness of colloidal layer of 25%, contained heteroatoms N, S, P and heteroatom content of 10% as raw material 100g of coking coal raw material dried at 120°C for 12h was put into a vibrating pulverizer for 10min, and then ball milled for 10 hours in a planetary ball mill, sieved with a 500-mesh sieve, and the undersize was taken.

[0082] (2) Add 50 g of dried, crushed and sieved coking coal into a mixed acid solution with a mass ratio of hydrofluoric acid and sulfuric acid of 2:1, the liquid-solid ratio is 6, and the total acid concentration is adjusted to a pH value of 4. The mixture was stirred and reacted for 5 hours, filtered and washed until neutral to obtain coke purified by acid method, and the ash content of the purified coke was 0.42%.

[0083] (3) Dissolve 20g of manganese acetate in 100ml of aqueous solution, add 1g of purified coke for ultrasonic dispersion ...

Embodiment 3

[0086] (1) Select coking coal with ash-free base volatile content of 20%, cohesive index of 58%, colloidal layer maximum thickness of 18%, contained heteroatoms N, S, P and heteroatom content of 8% as raw material 100g of bituminous coal raw material dried at 105°C for 10h was put into a vibratory pulverizer for crushing for 5min, then ball milled for 8 hours in a planetary ball mill, sieved with a 500-mesh sieve, and the undersize was taken.

[0087] (2) Add 50 g of dried, crushed and sieved coking coal into a mixed acid solution with a mass ratio of hydrofluoric acid and sulfuric acid of 10:1, the liquid-solid ratio is 5, and the total acid concentration is adjusted to a pH value of 3 at room temperature. The mixture was stirred and reacted for 5 hours, filtered and washed until neutral to obtain coke purified by acid method, and the ash content of the purified coke was 0.23%.

[0088] (3) Dissolve 10g of manganese acetate in 100ml of aqueous solution, add 50g of purified co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com