An online control method of liquid nitrogen injection amount for ultra-low temperature cooling processing

A control method and technology of injection quantity, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of inaccurate regulation, temperature regulation devices and methods that do not consider processing conditions, etc., and achieve strong operability. , The effect of fast control speed and small initial value error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

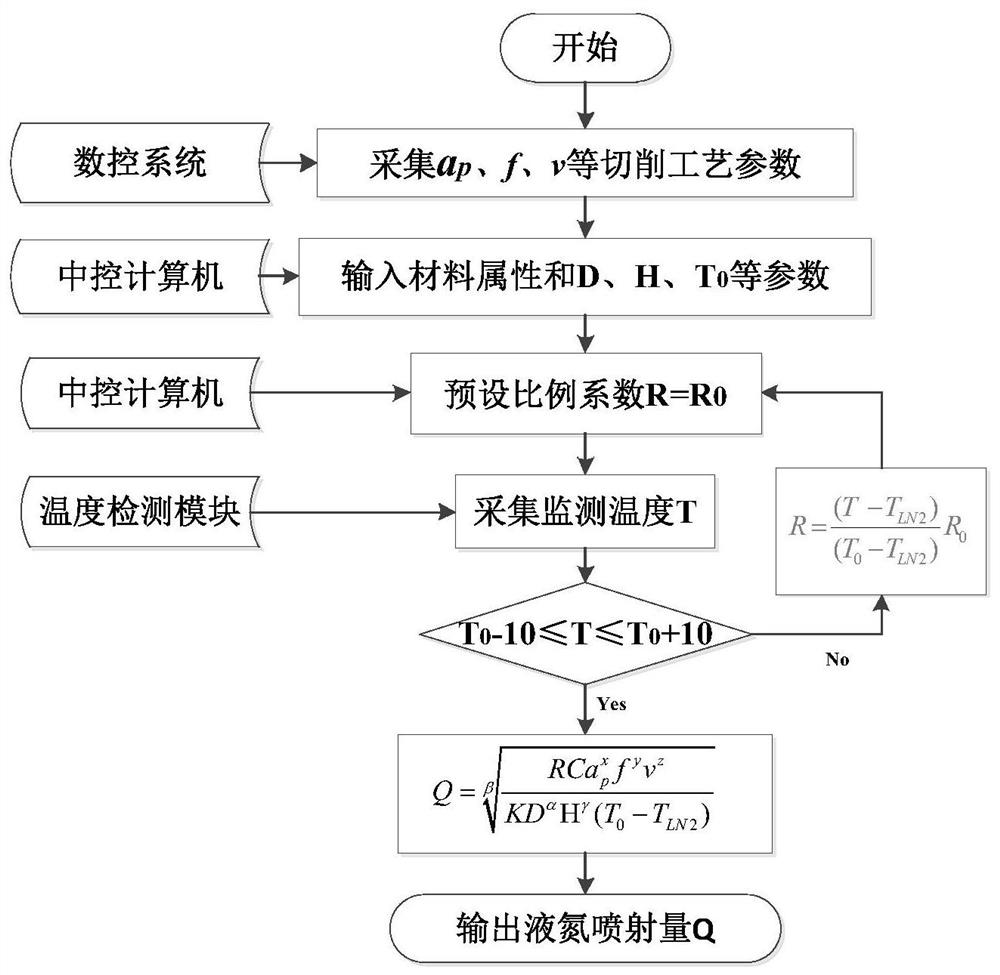

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

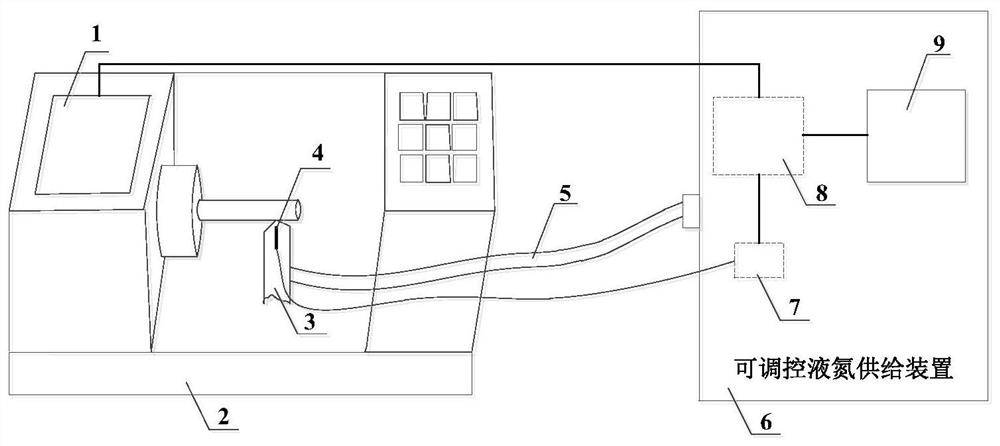

[0031] Taking the outer circle turning of titanium alloy (Ti-6Al-4V) as an example, the CNC lathe is used for processing, and the cutting process parameter is the cutting depth a p , feed rate f, cutting speed v, etc.; the material of the internal spray turning tool is hard alloy, the diameter of the nozzle on the tool is D = 3.0mm, and the distance between the nozzle and the tip of the tool is H = 15mm. The best cutting temperature for titanium alloy is T 0 = 180°C.

[0032] The first step is to establish a relationship model between cutting process parameters and liquid nitrogen injection volume

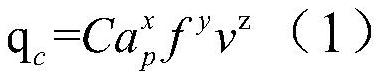

[0033] When the cemented carbide tool turns titanium alloy, the heat q generated per unit time c for:

[0034]

[0035] When the liquid nitrogen enters the internal injection tool (3) through the gas deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com