Novel graphite electrode manufacturing technology, and manufacturing equipment thereof

A graphite electrode and manufacturing process technology, which is applied in the manufacturing process of new graphite electrodes and its manufacturing equipment, can solve the problems of easy oxidation of the graphite electrode surface, achieve the effects of enhancing oxidation resistance, shortening the process cycle, and improving adhesion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

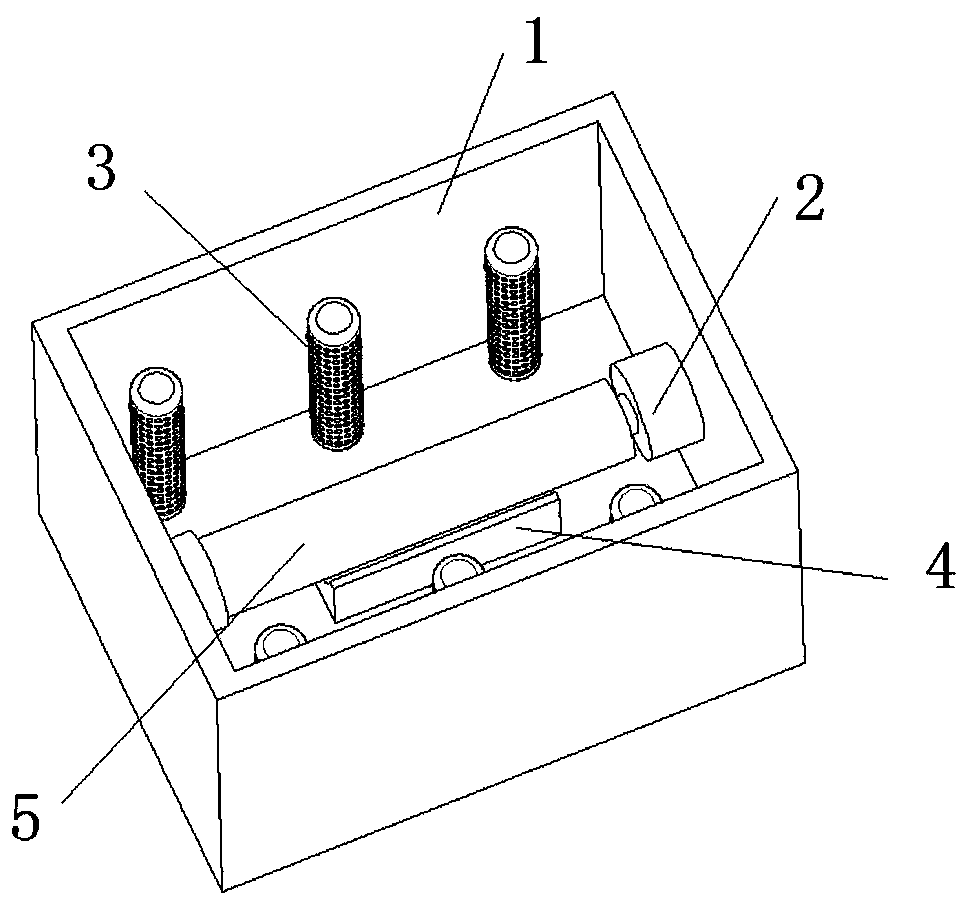

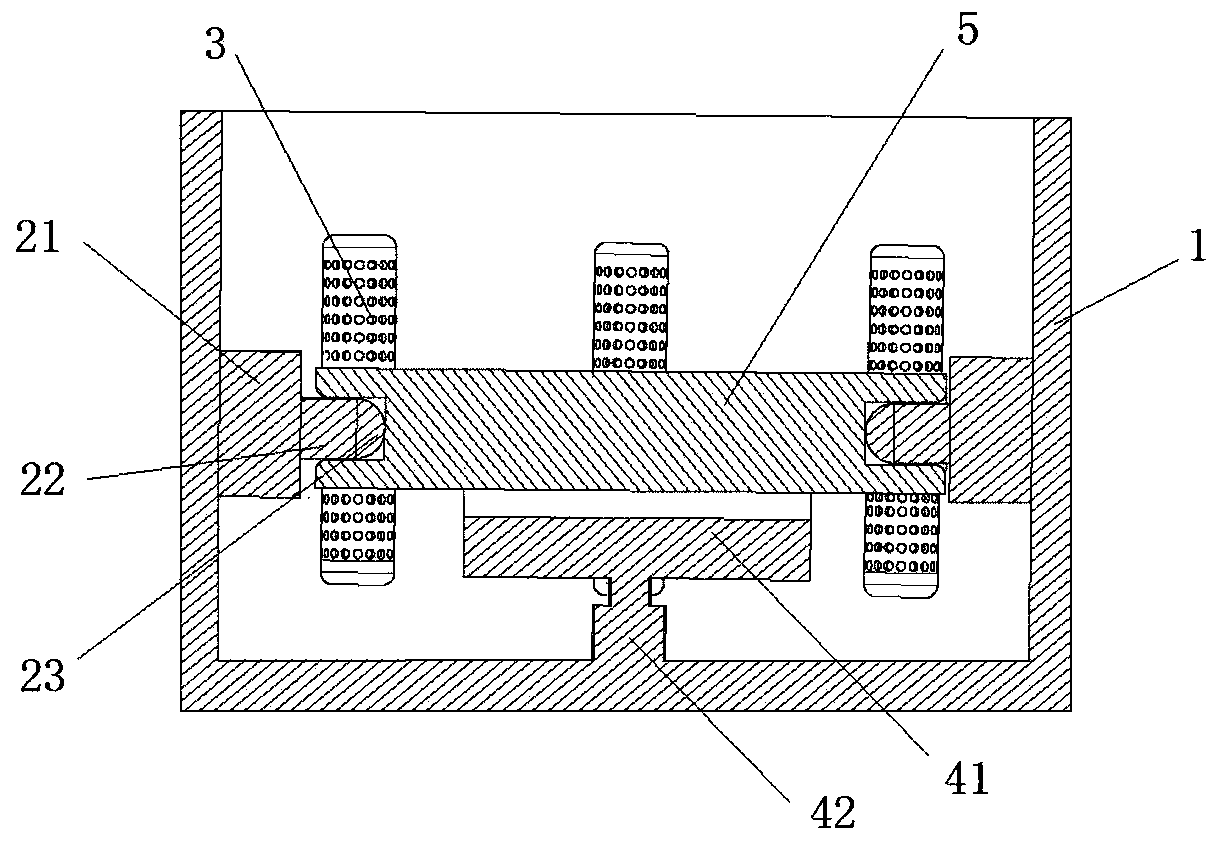

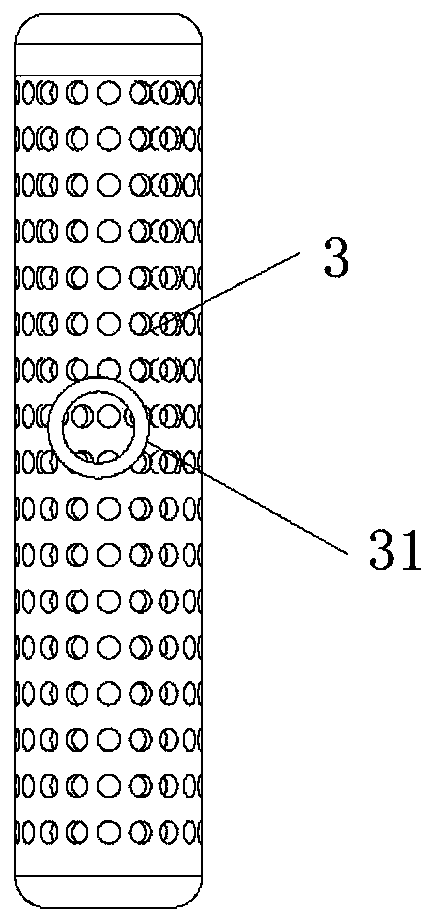

Image

Examples

Embodiment 1

[0045] A kind of manufacturing process of novel graphite electrode, comprises the following steps:

[0046] 1) Raw material preparation: Take 300 kg of petroleum coke, 200 kg of needle coke, and 100 kg of anthracite as raw materials in parts by weight.

[0047] 2) Calcination: Put petroleum coke and pitch coke into a closed calciner for calcination in parts by weight, heat to 1280°C, keep the calcination time at 0.5h, and continuously feed the protective gas helium.

[0048] 3) Grinding: The calcined petroleum coke and pitch coke are mixed and then crushed and finely ground.

[0049] 4) Stirring: continue to add anthracite to the raw materials in step 3), and control the stirring temperature to 300° C., and the stirring time to 3 hours, and mix, and control the relative air humidity at this time to 90%.

[0050] 5) Roll compaction: compact the stirred raw materials under a pressure of 14MPa, pre-compact for 2 hours, and pre-compact at a temperature of 120°C to form a green bo...

Embodiment 2

[0058] A kind of manufacturing process of novel graphite electrode, comprises the following steps:

[0059] 1) Raw material preparation: Take 300 kg of petroleum coke, 200 kg of needle coke, and 100 kg of anthracite as raw materials in parts by weight.

[0060] 2) Calcination: Put petroleum coke and pitch coke into a closed calciner for calcination in parts by weight, heat to 1300°C, keep the calcination time for 1 hour, and continuously feed the protective gas helium.

[0061] 3) Grinding: The calcined petroleum coke and pitch coke are mixed and then crushed and finely ground.

[0062] 4) Stirring: continue to add anthracite to the raw materials in step 3), and control the stirring temperature to 320° C., and the stirring time to 2.8 hours, and mix, and control the relative air humidity at this time to 87%.

[0063] 5) Roll compaction: compact the stirred raw materials under a pressure of 11 MPa, and pre-compact for 1.5 hours at a temperature of 130°C to form a green body. ...

Embodiment 3

[0071] A kind of manufacturing process of novel graphite electrode, comprises the following steps:

[0072] 1) Raw material preparation: Take 300 kg of petroleum coke, 200 kg of needle coke, and 100 kg of anthracite as raw materials in parts by weight.

[0073] 2) Calcination: Put petroleum coke and pitch coke into a closed calciner for calcination in parts by weight, heat to 1320°C, keep the calcination time at 0.5h, and continuously feed the protective gas helium.

[0074] 3) Grinding: The calcined petroleum coke and pitch coke are mixed and then crushed and finely ground.

[0075] 4) Stirring: continue to add anthracite to the raw materials in step 3), and control the stirring temperature to 400° C., and the stirring time to 2.5 hours, and mix, and control the relative air humidity at this time to 80%.

[0076] 5) Roll compaction: compact the stirred raw materials under a pressure of 11 MPa, and pre-compact for 1.5 hours at a temperature of 130°C to form a green body.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com