A high-permeability permeable concrete binder

A permeable concrete and high-permeability technology, applied in the field of building materials, can solve problems such as poor bonding effect and inability to meet road strength requirements, and achieve the effect of meeting water permeability requirements, excellent bonding effect, and meeting road strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

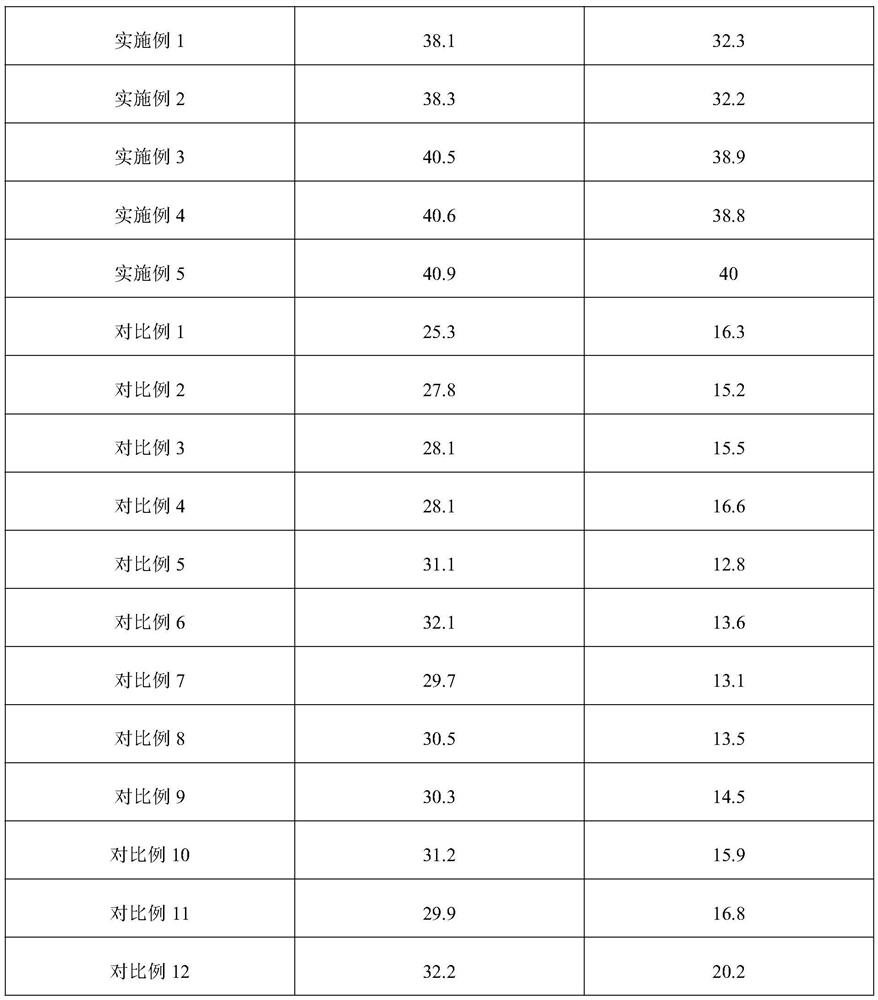

Embodiment 1

[0034] A high permeability permeable concrete cement, with a weight of mass, 15 parts of magnesium phosphate cement, 15 parts of polytegan siloxane, 25 parts of epoxy resin, 12 parts of phenolic resin, hydroxypropyl acrylate, propylene 3 parts of amide, 8 cellulose ethers, 3 parts of the active silica powder, 3 parts of the gelatin, 8 parts of polyvinyl alcohol, 6 pentaisaturate, 4 hydrated sulfide, calcium carbonate, 10 copies, twelve 3 parts of sodium alkylbenzene sulfonate, 1 part of 2,4-pentadiene salts, 3 cases of coupling agents, 4 defoamers, 45 water.

[0035] Among them, the zinc salt of 2,4-pentadiene is obtained by mixing 2,4-pentadienoic acid with a mass concentration of 12% a sodium hydroxide solution, so that pH = 8, add mass concentration. 10% of the zinc nitrate solution, stirred for 30 minutes, filtration, washing, drying, i.e., 2,4-pentadienic acid and zinc nitrate containing the molar ratio of 1: 1. Among them, it was washed twice with deionized water. The condit...

Embodiment 2

[0046] A high permeability permeable concrete cement, with a weight of 100 parts of magnesium phosphate cement, 20 parts of a polyorgan siloxane, 35 parts of epoxy resin, 15 parts of phenolic resin, 18 hydroxypropyl acrylate, propylene 6 parts of amide, 10 cellulose ethers, 8 parts of the active silica powder, 4 parts of the gelatin, 10 polyvinyl alcohol, 9 pentaisaturate, 7 hydrated sulfide, calcium carbonate, 12 copies, 12 2 parts of sodium alkylbenzenesulfonate, 2 parts of 2,4-pentadiene salts, 4 parts of coupling agent, 5 parts of defoam, 55 water.

[0047] Among them, the zinc salt of 2,4-pentadienate is obtained by mixing 2,4-pentadiene, a hydroxide solution having a mass concentration of 12%, so that pH = 10, add mass concentration. 10% of the zinc nitrate solution, stirred for 40 minutes, filtration, washing, drying, i.e., the molar ratio of zinc nitrate containing the zinc nitrate and the zinc nitrate solution of 1: 1.2. Among them, 3 times was washed with deionized water...

Embodiment 3

[0058] A high permeable permeable concrete cement, with a mass of 100 parts of magnesium phosphate, 15 parts of polytegan siloxane, 35 parts of epoxy resin, 12 parts of phenolic resin, hydroxypropyl acrylate, propylene 3 parts of amide, 10 cellulose ethers, 3 parts of the active silica powder, 3 parts of the gelatin, 10 parts of polyvinyl alcohol, 6 of the pentaerythyl alcohol, 7 hydrated sulfide, 20 copies of calcium carbonate, twelve 4 parts of sodium alkylbenzene sulfonate, 1 part of 2,4-pentadiene salts, 4 parts of the coupling agent, 4 parts of antifoam, 55 water.

[0059] Among them, the calcium carbonate crystal must perform organic modification, and the specific method is to immerse calcium carbonate in the polyethylene glycol 400, stand for 3 hours, filtered, then immerse into the polyglycerol ricin, ultrasonic oscillation 30 Minute, filtration, drying, The ratio of calcium carbonate should, polyethylene glycol 400, polyglycerol ricinate is 1: 8: 10.

[0060] The zinc sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com