Additive manufacturing method of prosthesis

A technology of additive manufacturing and prosthesis, applied in the direction of bone implants, etc., can solve the problem of unequal prosthesis strength and surface finish, and achieve the effects of saving preparation time, reducing surface roughness, and improving finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

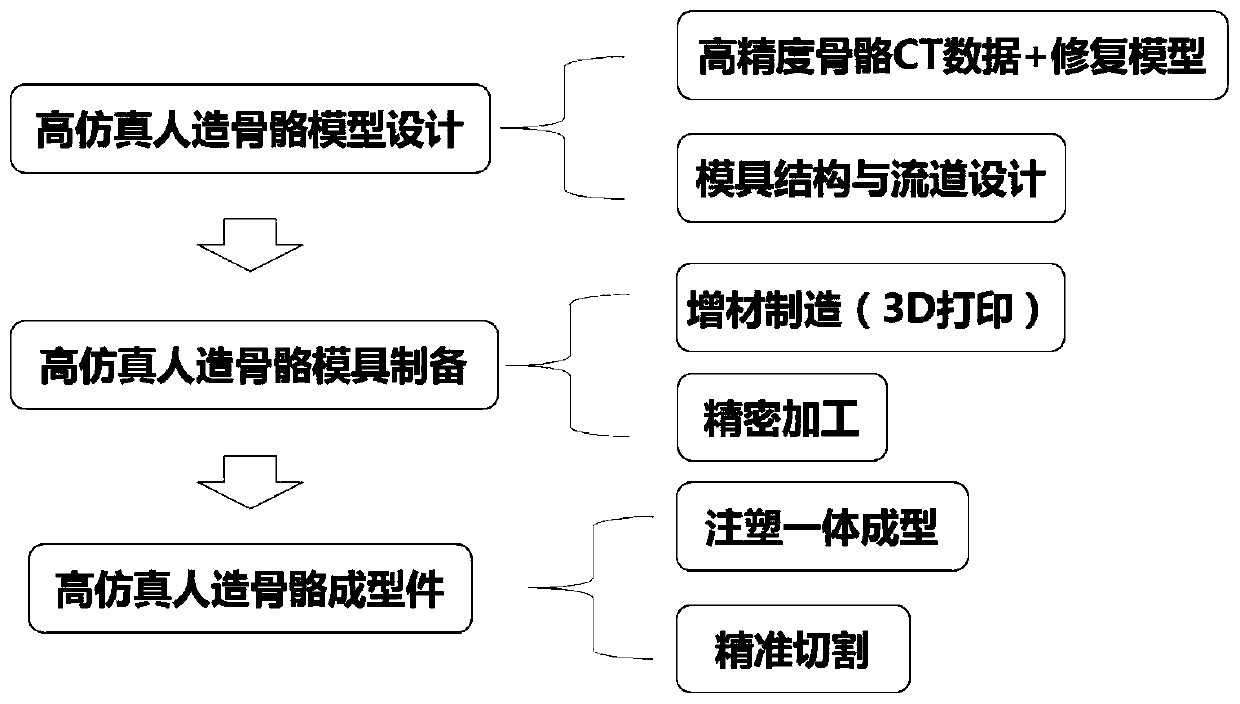

[0098] Preferably, the high-precision CT scanning technology realizes the high-precision modeling of the bone affected area combined with the position design of the injection runner to obtain a high-precision digital model suitable for additive manufacturing.

[0099] Preferably, the powder sintering technology (SLS) of additive manufacturing uses spherical powder of stainless steel 316L to prepare the metal injection mold.

[0100] Preferably, the injection mold obtained by additive manufacturing is polished, and the surface roughness Ra is 0.005; the surface roughness is further reduced through the electroplating process.

[0101] Preferably, the PEEK material of VICTREX is used for injection molding to simulate artificial bones with high precision.

[0102] Preferably, the positioning function of the surgical navigation template is used to determine the cutting point and the cutting surface to obtain a high-precision and high-simulation PEEK artificial bone that can be used for tran...

Embodiment 2

[0113] Preferably, the high-precision CT scanning technology realizes the high-precision modeling of the bone affected area combined with the position design of the injection runner to obtain a high-precision digital model suitable for additive manufacturing.

[0114] Preferably, the powder sintering technology (SLS) of additive manufacturing uses spherical powder of stainless steel 316L to prepare the metal injection mold.

[0115] Preferably, the injection mold obtained by additive manufacturing is polished, and the surface roughness Ra is 0.01; through the electroplating process, the surface roughness is further reduced.

[0116] Preferably, the PEEK material of VICTREX is used for injection molding to simulate artificial bones with high precision.

[0117] Preferably, the positioning function of the surgical navigation template is used to determine the cutting point and the cutting surface to obtain a high-precision and high-simulation PEEK artificial bone that can be used for tran...

Embodiment 3

[0128] Preferably, the high-precision CT scanning technology realizes the high-precision modeling of the bone-affected part; combined with the position design of the injection runner, a high-precision digital model suitable for additive manufacturing is obtained.

[0129] Preferably, the powder sintering technology (SLS) of additive manufacturing uses spherical powder of stainless steel 316L to prepare the metal injection mold.

[0130] Preferably, the injection mold obtained by additive manufacturing is polished, and the surface roughness Ra is 0.015; the surface roughness is further reduced through the electroplating process.

[0131] Preferably, the PEEK material of VICTREX is used for injection molding to simulate artificial bones with high precision.

[0132] Preferably, the positioning function of the surgical navigation template is used to determine the cutting point and the cutting surface to obtain a high-precision and high-simulation PEEK artificial bone that can be used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com