Highly-tolerant organic solvent separation membrane and preparation method thereof

An organic solvent and separation membrane technology, applied in the field of high tolerance organic solvent separation membrane and its preparation, can solve the problems of high temperature, PEEK crystal structure damage, difficult application, etc., and achieve strong high temperature resistance, acid and alkali resistance, Effect of good solubility and processability, excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a highly resistant organic solvent separation membrane, comprising the following steps:

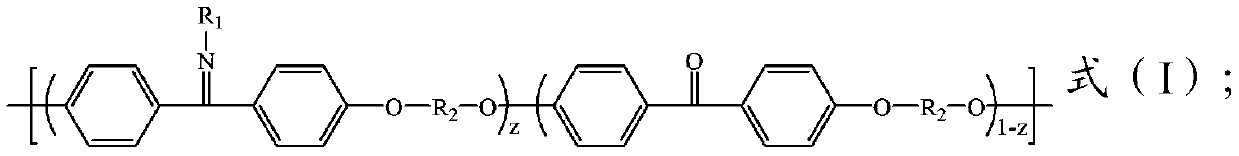

[0030] a) using a phase inversion method to make the casting liquid into a film to obtain an asymmetric film; the casting liquid includes a solvent and a polymer containing a Schiff base structure;

[0031] b) placing the asymmetric membrane in an acid solution for acidification to obtain a separation membrane with high tolerance to organic solvents.

[0032] In the preparation method provided by the present invention, firstly, a casting solution is provided, and the casting solution includes a solvent and a polymer containing a Schiff base structure. Wherein, the solvent includes but is not limited to one of N,N-dimethylformamide, N,N-dimethylacetamide, N-methylpyrrolidone, 1,4-dioxane and tetrahydrofuran or Various. In an embodiment provided by the present invention, the solvent includes N-methylpyrrolidone and tetrahydrofuran, and ...

Embodiment 1

[0069] The dihalogen monomer (wherein R of 1mol formula (II) structure 1 Be phenyl, X is-F), the diphenol monomer (R of 1mol formula (IV) structure 2 is phenyl) and 2.01mol anhydrous K 2 CO 3 Add it to a 2L three-necked flask with mechanical stirring, water separator and condenser, and add 1L N-methylpyrrolidone, then add 300mL toluene, and 2 Heated to 140°C with water for 2 hours under the atmosphere, then evaporated the water-carrying agent and polymerized at 170°C for 6 hours, then settled the polymer into water, washed with deionized water several times, and dried in vacuum at 100°C for 24 hours to obtain The polymer of formula (i) structure:

[0070]

[0071] In formula (i), R 1 , R 2 All are phenyl, z=1, n=200.

Embodiment 2

[0073] With the dihalogen monomer (wherein R of 0.8mol formula (II) structure 1 is phenyl, X is -F), 0.2 mol of the dihalogen monomer of the formula (III) structure (wherein X is -F), 1 mol of the diphenol monomer of the formula (IV) structure (R 2 is phenyl) and 2.01mol anhydrous K 2 CO 3Add it to a 2L three-necked flask with mechanical stirring, water separator and condenser, and add 1L N-methylpyrrolidone, then add 300mL toluene, and 2 Heated to 140°C with water for 2 hours under the atmosphere, then evaporated the water-carrying agent and polymerized at 170°C for 6 hours, then settled the polymer into water, washed with deionized water several times, and dried in vacuum at 100°C for 24 hours to obtain The polymer of formula (i) structure (wherein, R 1 , R 2 Both are phenyl, z=0.8, n=200).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com