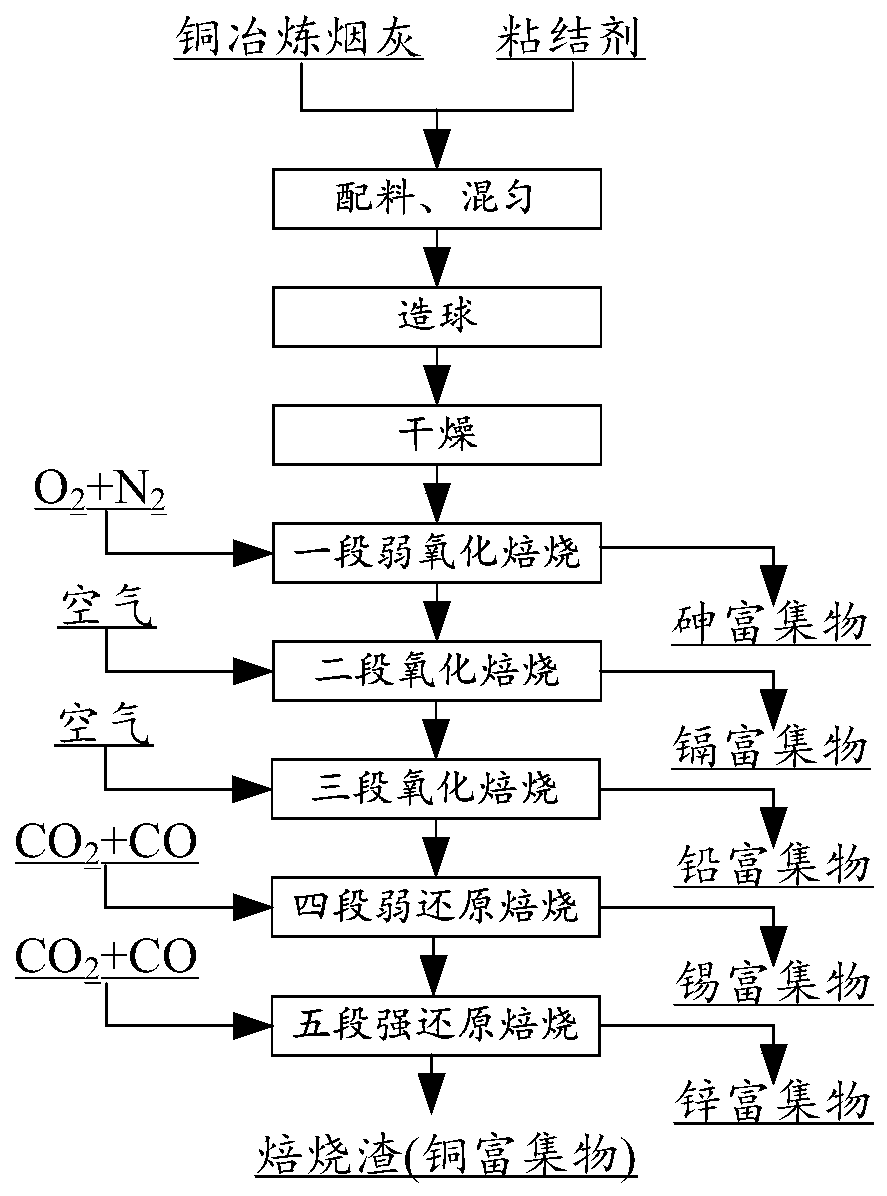

A method for separating and recovering valuable metals in copper smelting soot by multi-stage controlled atmosphere roasting

A technology for copper smelting soot and valuable metals, which is applied to the treatment of copper smelting soot, copper smelting soot full-fire recovery of valuable metals, multi-stage controlled atmosphere roasting to separate and recover valuable metals in copper smelting soot, which can solve energy consumption High pollution, high pollution, low comprehensive recovery rate of metal elements, etc., to achieve the effect of low energy consumption, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using soot from a copper smelter (metal content is Cu7.6%, As13.5%, Cd2.3%, Pb23.2%, Sn1.8%, Zn18.3%) as raw material, the weight ratio of copper ash is 3% % of bentonite and 8.0% of water, mixed evenly to make pellets, and multi-stage roasting after the raw pellets are dried. The first-stage calcination temperature is 400°C, and the calcination atmosphere is O 2 / (O 2 +N 2 ) = 5.0%, the roasting time is 180min, and arsenic-rich dust (66.3% of arsenic content) is recovered from the dust removal system; the second-stage roasting temperature is 900°C, the roasting atmosphere is air, and the roasting time is 120min, and the cadmium-rich dust is recovered from the dust removal system Soot (cadmium content 79.8%); the three-stage roasting temperature is 950°C, the roasting atmosphere is air, the roasting time is 120min, and the lead-rich smoke (lead content 86.3%) is recovered from the dust removal system; the fourth-stage roasting temperature is 950°C, the roasting atmosp...

Embodiment 2

[0027] Using soot from a copper smelter (metal content is Cu7.6%, As13.5%, Cd2.3%, Pb23.2%, Sn1.8%, Zn18.3%) as raw material, the mass ratio of copper ash is 1 % of sodium humate binder and 10.0% of water, after mixing evenly, pelletizing is carried out, and after the green pellets are dried, multi-stage roasting is carried out. The first-stage calcination temperature is 600°C, and the calcination atmosphere is O 2 / (O 2 +N 2) = 0.5%, the roasting time is 120min, and the arsenic-rich dust (arsenic content 68.3%) is recovered from the dust removal system; the second-stage roasting temperature is 600°C, the roasting atmosphere is air, and the roasting time is 180min, and the cadmium-rich dust is recovered from the dust removal system Soot (cadmium content 75.4%); the three-stage roasting temperature is 1050 ° C, the roasting atmosphere is air, the roasting time is 180 minutes, and the lead-rich smoke dust (lead content 84.9%) is recovered from the dust removal system; the four...

Embodiment 3

[0029] Using soot from a copper smelter (metal content is Cu10.2%, As16.2%, Cd1.9%, Pb20.7%, Sn2.1%, Zn15.4%) as raw material, the mass ratio of copper ash is 2 % of CMC and 9.0% of water, mixed evenly to make pellets, and multi-stage roasting after the green pellets are dried. The first-stage calcination temperature is 500°C, and the calcination atmosphere is O 2 / (O 2 +N 2 )=1.5%, the roasting time is 120min, and the arsenic-rich dust (69.4% of arsenic content) is recovered from the dust removal system; the second-stage roasting temperature is 800°C, the roasting atmosphere is air, the roasting time is 120min, and the cadmium-rich dust is recovered from the dust removal system Soot (cadmium content 79.4%); the three-stage roasting temperature is 1000 ° C, the roasting atmosphere is air, the roasting time is 180 minutes, and the lead-rich smoke dust (lead content 80.8%) is recovered from the dust removal system; the fourth-stage roasting temperature is 1050 ° C, the roastin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com