Method of Mechanochemical Coupling Ultrasonic Chemical Enhancement of Metal Leaching in Secondary Zinc Oxide Powder

A secondary zinc oxide and sonochemical technology, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical/physicochemical processes that apply energy, etc., can solve the problem of reducing the operating life of equipment and increasing the energy of production Consumption, uneven mixing of slurry and other problems, to achieve the effect of reducing the concentration of use, significant technical benefits, and low reaction energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

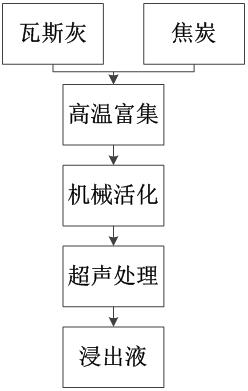

Method used

Image

Examples

Embodiment 1

[0033] Using 1.0 g secondary zinc oxide powder as the reaction raw material, the primary zinc oxide powder was firstly subjected to mechanochemical activation reaction in the ball mill tank of the ball mill. The ball milling speed was 400 rpm, the ball milling time was 1.0 h, and the ball-to-material ratio was 40:1. The secondary zinc oxide powder after the mechanochemical activation reaction is taken out from the ball mill tank, and the secondary zinc oxide powder is leached in an acidic leaching solution, and the pH value of the acidic leaching solution is set to 4.5. During the leaching process, the reaction power of the ultrasonic instrument was 25 kHz, the leaching time was 5.0 min, and the reaction temperature was 25 degrees at room temperature. The content of elements in the obtained leaching solution was measured by full-spectrum direct-reading plasma emission spectrometry, and the leaching efficiencies of zinc, iron, cobalt and nickel can reach 95.4%, 92.7%, 93.1% and ...

Embodiment 2

[0035] Using 1.0 g secondary zinc oxide powder as the reaction raw material, the primary zinc oxide powder was first subjected to mechanochemical activation reaction in the ball mill tank, the ball milling speed was 500 rpm, the ball milling time was 2.0 h, and the ball-to-material ratio was 50:1. The secondary zinc oxide powder after the mechanochemical activation reaction is taken out from the ball mill tank, and the secondary zinc oxide powder is leached in an acidic leaching solution, and the pH value of the acidic leaching solution is set to 5.0. During the leaching process, the acidic leaching solution was placed in ultrasonic instruments of different powers to investigate the improvement efficiency of mechanochemical activation reaction coupling ultrasonic chemistry on metal leaching from secondary zinc oxide powder. The reaction power of the ultrasonic equipment is 35 kHz, the leaching time is 3.0 min, and the reaction temperature is 25 degrees at room temperature. The...

Embodiment 3

[0037]Using 1.0 g of secondary zinc oxide powder as the reaction raw material, the secondary zinc oxide powder was firstly subjected to mechanochemical activation reaction in the ball mill tank of the ball mill. The ball milling speed was 600 rpm, the ball milling time was 3.0 h, and the ball-to-material ratio was 60:1. The secondary zinc oxide powder after the mechanochemical activation reaction is taken out from the ball mill tank, and the secondary zinc oxide powder is leached in an acidic leaching solution, and the pH value of the acidic leaching solution is set to 5.5. During the leaching process, the acidic leaching solution was placed in ultrasonic instruments of different powers to investigate the improvement efficiency of mechanochemical activation reaction coupling ultrasonic chemistry on metal leaching from secondary zinc oxide powder. The reaction power of the ultrasonic equipment is 40 kHz, the leaching time is 1.0 min, and the reaction temperature is 18 degrees. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com