Building ceramic material and preparation method thereof

A technology of architectural ceramics and materials, applied in the field of architectural ceramic materials, can solve the problems of poor apparent porosity and low tensile strength, and achieve the effects of increased density, adjustable porosity, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A building ceramic material, which is prepared from the following raw materials in parts by weight: 40 parts of fly ash, 35 parts of red mud, 5 parts of coal powder, 6 parts of bentonite, and 3 parts of borax;

[0036] Wherein, the building ceramic material is prepared through the following steps:

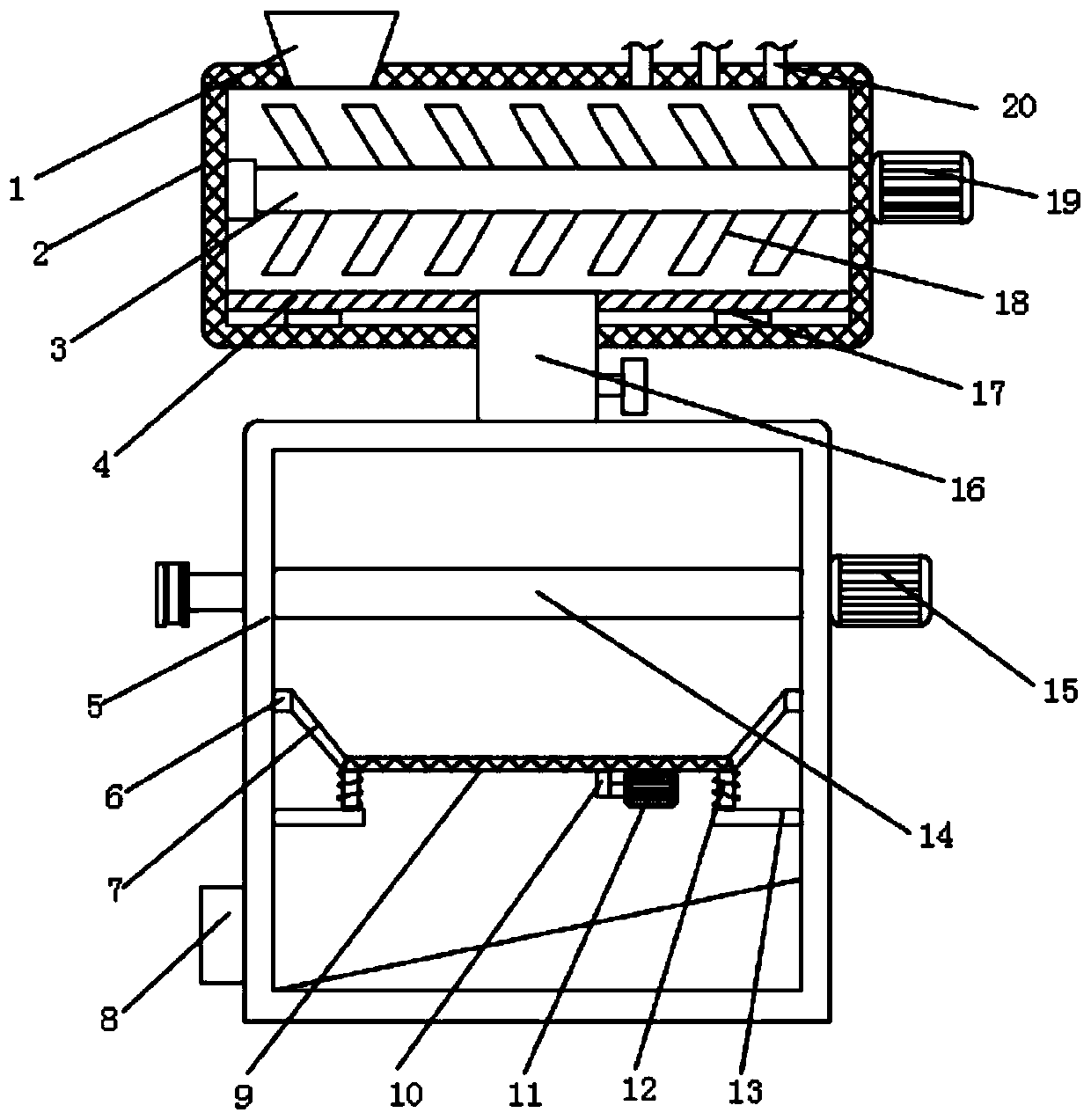

[0037] Step 1. Pour fly ash, red mud, pore-forming agent, binder and sintering aid into the mixing cylinder 2 through the feeding funnel 1 of the screening device, and the heater 17 heats it, and the second rotating motor 19 Drive the stirring shaft 3 and the stirring rod 18 to stir, stir, heat and dry for 20 minutes;

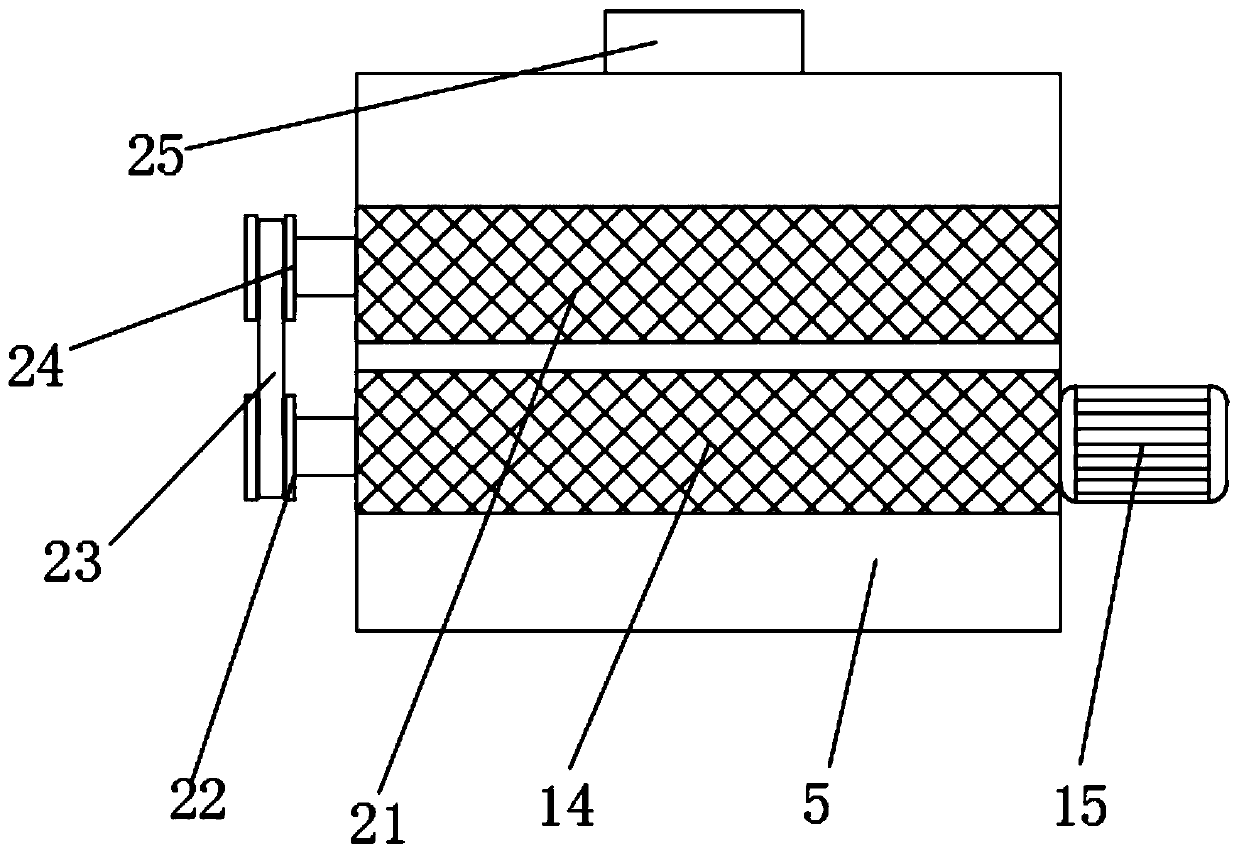

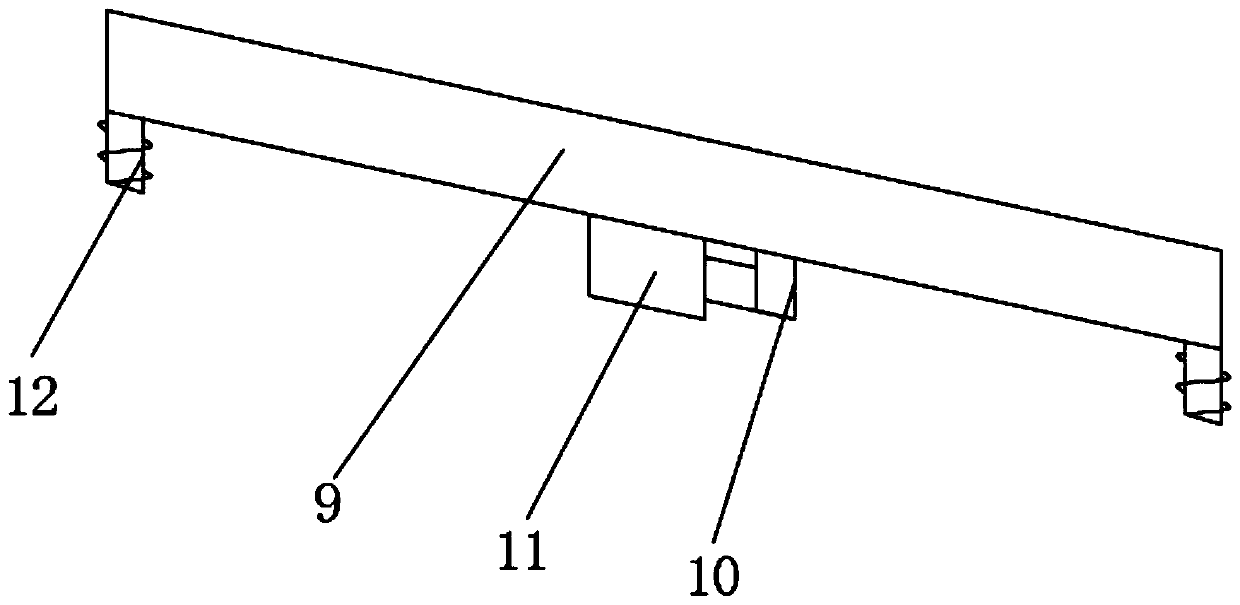

[0038] Step 2, open the electric control valve, transport the dried material in step 1 to the screening cylinder 5, firstly grind it through the first grinding roller 14 and the second grinding roller 21, and the rotation speed of the grinding roller is 200 rpm; After the ground material is filtered through the screen 9, various materials are obtained;

[0...

Embodiment 2

[0042] A building ceramic material, which is prepared from the following raw materials in parts by weight: 30 parts of fly ash, 20 parts of red mud, 1 part of coal powder, 3 parts of bentonite, and 1 part of borax;

[0043] Wherein, the building ceramic material is prepared through the following steps:

[0044] Step 1. Pour fly ash, red mud, pore-forming agent, binder and sintering aid into the mixing cylinder 2 through the feeding funnel 1 of the screening device, and the heater 17 heats it, and the second rotating motor 19 Drive the stirring shaft 3 and the stirring rod 18 to stir, stir, heat and dry for 10 minutes;

[0045] Step 2, open the electric control valve, transport the dried material in step 1 to the screening cylinder 5, firstly grind it through the first grinding roller 14 and the second grinding roller 21, and the rotation speed of the grinding roller is 200 rpm; After the ground material is filtered through the screen 9, various materials are obtained;

[004...

Embodiment 3

[0049] A building ceramic material, which is prepared from the following raw materials in parts by weight: 35 parts of fly ash, 30 parts of red mud, 3 parts of coal powder, 4 parts of bentonite, and 2 parts of borax;

[0050] Wherein, the building ceramic material is prepared through the following steps:

[0051] Step 1. Pour fly ash, red mud, pore-forming agent, binder and sintering aid into the mixing cylinder 2 through the feeding funnel 1 of the screening device, and the heater 17 heats it, and the second rotating motor 19 Drive the stirring shaft 3 and the stirring rod 18 to stir, stir, heat and dry for 30 minutes;

[0052] Step 2, open the electric control valve, transport the dried material in step 1 to the screening cylinder 5, firstly grind it through the first grinding roller 14 and the second grinding roller 21, and the rotation speed of the grinding roller is 200 rpm; After the ground material is filtered through the screen 9, various materials are obtained;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com