High-space velocity catalyst for hydrogen production from methanol-water and preparation method and application thereof

A methanol water and catalyst technology, which is applied to the high space velocity methanol water hydrogen production catalyst and the field of preparation thereof, can solve the problems of instability, lack, and short service life of the catalyst, and achieve the effect of promoting the decomposition of methanol and steam reforming, and the ratio of The effect of increased surface area, enhanced capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

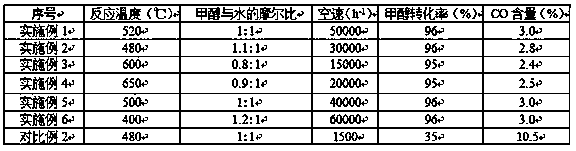

Examples

Embodiment 1

[0029] A high space velocity methanol-water hydrogen production catalyst, which contains a modified cerium-zirconium oxide solid solution support with a mass fraction of 81%, and an active component with a mass fraction of 19%; the active component includes Pt and MnO 2 , the mass of the Pt accounts for 26% of the active component mass, the MnO 2 The mass accounts for 74% of the active component mass; the molecular formula of the modified cerium-zirconium oxide solid solution carrier is: Ce 0.7 Zr 0.3 Zn 0.1 (La 0.05 Y 0.05 ) 0.1 o 2.25 , where O is oxygen, and M is La and Y in rare earth metals.

[0030] The preparation method of the methanol water hydrogen production catalyst of high space velocity described in the present embodiment, it comprises the steps:

[0031] (1) Preparation of modified cerium-zirconium oxide solid solution carrier: The modified cerium-zirconium oxide solid solution carrier was prepared by coprecipitation method or sol-gel method, specifically...

Embodiment 2

[0036] A high space velocity methanol-water hydrogen production catalyst, which contains a modified cerium-zirconium oxide solid solution support with a mass fraction of 90%, and an active component with a mass fraction of 10%; the active component includes Pt and MnO 2 , the mass of the Pt accounts for 40% of the active component mass, the MnO 2 The mass accounts for 60% of the active component mass; the molecular formula of the modified cerium-zirconium oxide solid solution carrier is: Ce 0.6 Zr 0.4 Zn 0.07 La 0.05 o 2.145 , where O is oxygen, and M is La in rare earth metals.

[0037] The preparation method of the methanol water hydrogen production catalyst of high space velocity described in the present embodiment, it comprises the steps:

[0038] (1) Preparation of modified cerium-zirconium oxide solid solution carrier: The modified cerium-zirconium oxide solid solution carrier was prepared by coprecipitation method or sol-gel method, specifically, 260.5g cerium nitr...

Embodiment 3

[0042] A high space velocity methanol-water hydrogen production catalyst, which contains a modified cerium-zirconium oxide solid solution support with a mass fraction of 95%, and an active component with a mass fraction of 5%; the active component includes Pt and MnO 2 , the mass of the Pt accounts for 20% of the active component mass, the MnO 2 The mass accounts for 80% of the active component mass; the molecular formula of the modified cerium-zirconium oxide solid solution carrier is: Ce 0.65 Zr 0.35 Zn 0.09 Y 0.02 o 2.12 , where O is oxygen, and M is Y in rare earth metals.

[0043] The preparation method of the methanol water hydrogen production catalyst of high space velocity described in the present embodiment, it comprises the steps:

[0044] (1) Preparation of modified cerium-zirconium oxide solid solution carrier: The modified cerium-zirconium oxide solid solution carrier was prepared by coprecipitation method or sol-gel method, specifically, 282.2g cerium nitrat...

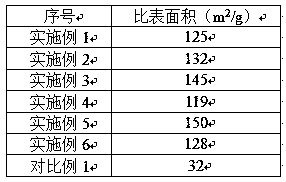

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com