Method for extracting microalgae grease by using supercritical carbon dioxide entraining ethanol

A technology of carbon dioxide and microalgae oil, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of weakening the influence of solvent solubility and mass transfer performance, high puffing temperature, high oil recovery rate, etc., and achieve green extraction process Environmental protection, simple operation, and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

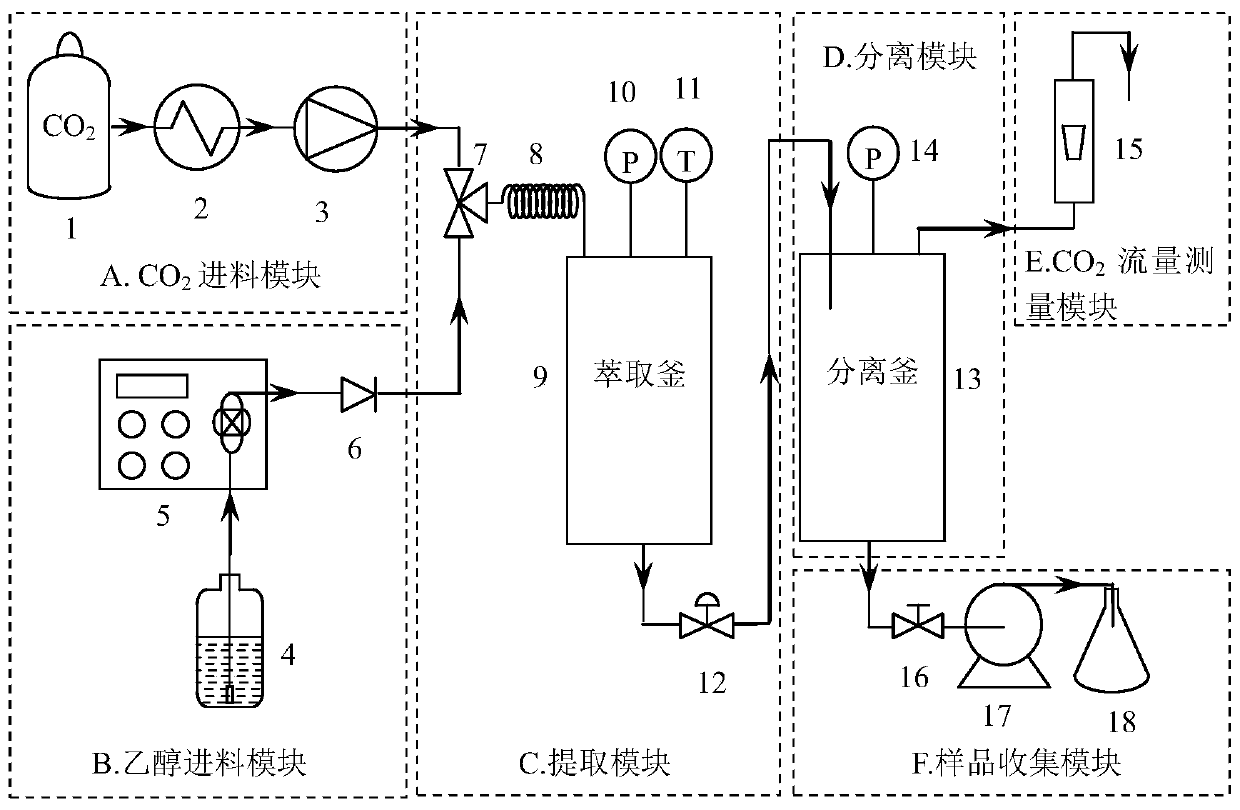

[0057] Device example 1, a kind of supercritical carbon dioxide entrained ethanol extraction device, such as image 3 As stated, by CO 2 Feed module A, ethanol feed module B, extraction module C, separation module D, CO 2 Composed of a flow measurement module E and a sample collection module F;

[0058] CO 2 Feed module A includes CO 2 Steel cylinder 1, low-temperature water tank 2, plunger pump 3, ethanol feeding module B includes reagent bottle 4, high-efficiency liquid phase pump 5, check valve 6, extraction module C includes mixer 7, preheating coil 8, extraction kettle 9, Pressure gauge 10, thermometer 11, expansion valve 12, separation module D includes separation kettle 13, pressure gauge 14, CO 2 The flow measurement module E includes a rotameter 15 (the rotameter 15 has a valve), and the sample collection module F includes a valve 16 , a peristaltic pump 17 , and a sample collection bottle 18 .

[0059] CO 2 Steel cylinder 1, low-temperature water tank 2, and pl...

Embodiment 1

[0064] Embodiment 1, a kind of technology that supercritical carbon dioxide entrains ethanol to extract microalgae oil, carries out following steps successively:

[0065] 1) Pretreatment of raw materials:

[0066] Centrifuge the microalgae fermentation broth at 4°C and 8000r / min for 20 minutes to collect the microalgae cells, then freeze-dry them at -53°C and 0.1mbar to constant weight, grind them, and pass through an 80-mesh sieve. The freeze-dried powder of microalgae is prepared.

[0067] 2), extraction:

[0068] Weigh 20.0g microalgae freeze-dried powder, mix with equal mass (20g) glass microspheres (the particle diameter of glass microspheres is about 2-3mm), place in the extraction kettle 9 of the supercritical extraction system, set the extraction kettle The temperature in 9 is 50-52°C, the pressure is 37-39MPa, and the plunger pump 3 is used to supply CO 2 Pressurize, control the flow rate to 5L / min (CO 2 At 25°C, the flow rate under 0.1MPa), the expansion valve 12...

Embodiment 2

[0075] Embodiment 2, a kind of technique of supercritical carbon dioxide extraction microalgae oil,

[0076] With respect to step 2) of embodiment 1, make the following changes: control the flow rate of entrainer ethanol (about 0.62mL / min) by high-efficiency liquid phase pump 5, so that the molar fraction of ethanol in the fluid is 0.05mol / mol, and all the other are equivalent In Example 1. The extraction time remains unchanged at 3 hours.

[0077] A total of 4.24g of microalgae oil was obtained; the recovery rate was 85.1%.

[0078] After the above-mentioned microalgae oil was methylated with 10% (w / w) acetyl chloride methanol solution, gas chromatography analysis was carried out, and its composition and content were as follows: myristic acid 6.1%, palmitic acid 40.3%, stearic acid 1.3% %, hexadecenoic acid 2.5%, oleic acid 2.7%, docosapentaenoic acid (DPA) 7.4%, docosahexaenoic acid (DHA) 38.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com