A Calculation Method of Trimming Points Based on Binocular Vision

A technology of binocular vision and calculation method, which is applied in the directions of calculation, image analysis, image enhancement, etc., and can solve the problems of low precision, the detection accuracy of precision instruments, and the inability to fully describe the geometric characteristics of spatial boundaries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and examples.

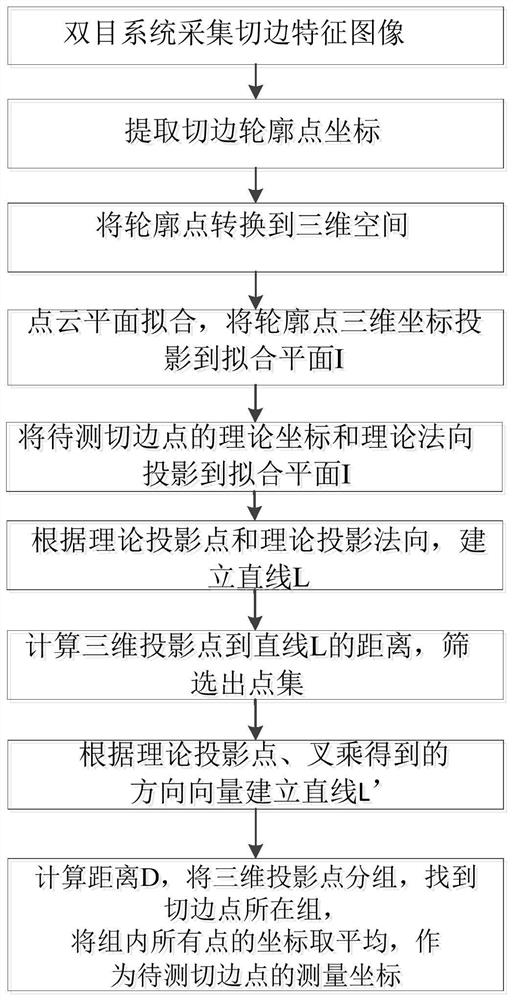

[0030] A cutting point calculation method based on binocular visual, including the following steps:

[0031] 1) Use the binocular visual measurement system to collect the left and right grayscale images of the cutting edge characteristics;

[0032] 2) For the left, right images, the graphic filter, two-value image, edge detection and other image pretreatment, extract the two-dimensional point coordinate N of the cutofline edge of the left and right images N t , T = 1, 2, ... s; s is the number of two-dimensional points of the contour edge edge;

[0033] 3) Use the polar match method to convert the cut-edge profile points in the left and right images to the three-dimensional point coordinate data of the cut-edge profile;

[0034] 4) Using the three-dimensional scanner to obtain the three-dimensional dot cloud of the plane of the measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com