A method for preparing dephenolized oil and phenolic resin from medium and low temperature coal tar

A technology for low-temperature coal tar and phenolic resin, which is applied in the field of preparing dephenolic oil and phenolic resin from medium-low temperature coal tar, can solve the problems of increasing investment cost, aggravating thermal condensation reaction, numerous equipment, etc., achieving low production and operation cost, avoiding oil The effect of poor product quality and reduction of hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

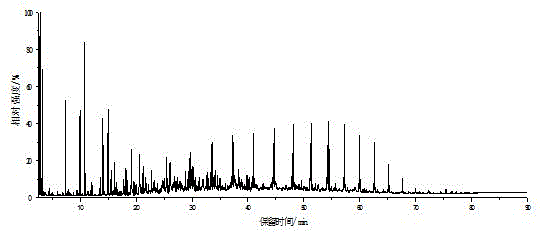

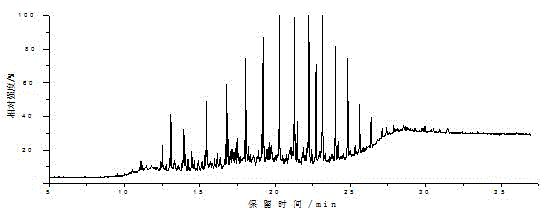

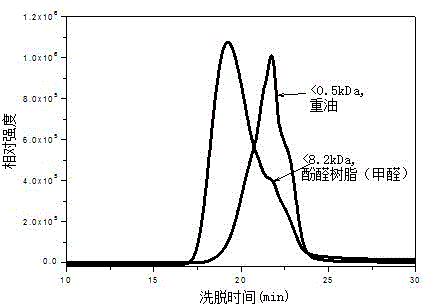

[0033] Weigh 30g of medium and low temperature coal tar into the reaction kettle and add an appropriate amount of zeolite, add 1mL of concentrated sulfuric acid, mix the coal tar and concentrated sulfuric acid evenly, then raise the temperature to 80~90°C, add 27mL of 37-40% formaldehyde solution, react for 2-3 hours, and let it cool for 30 minutes. The reaction mixture was repeatedly washed with toluene as a solvent, the soluble part was distilled at 90°C and 0.01 MPa to obtain dephenolized oil, and the insoluble part was distilled under reduced pressure at 80-90°C to obtain a phenolic resin; gas chromatography-mass spectrometry was used to The composition of the dephenolized oil was analyzed, and the molecular weight of the phenolic resin was determined by gel chromatography.

[0034]

[0035]

[0036]

[0037] combine figure 1 , 2 And the results in Table 2 found that the medium and low temperature coal tar in northern Shaanxi is rich in phenolic compounds. After...

Embodiment 2

[0039] Put 500g of medium and low temperature coal tar in a distillation bottle and add an appropriate amount of zeolite, slowly raise the temperature, and collect distillation ranges at > Distillations within each distillation range at 300°C.

[0040] Weigh 10g > 300°C fraction and 7.5mL NaOH (40wt%) were placed in a flask, 27mL formaldehyde solution (37wt%) was added, and the temperature was raised to 80-90°C for 1.5h to obtain an oil layer above the water phase in the reactor (dephenolized oil ) and the reaction mixture (phenolic resin and partially dephenolized oil) under water. The reaction mixture was repeatedly washed with toluene as a solvent, the soluble part was incorporated into dephenolized oil, and the insoluble part was distilled off under reduced pressure at 80-90°C to obtain phenolic resin; the composition of the dephenolized oil was analyzed by gas chromatography-mass spectrometry , using infrared spectroscopy to analyze the phenolic resin.

[0041]

[00...

Embodiment 3

[0045] Take by weighing the 10g that embodiment 2 distillation obtains > 300 ° C distillate and 5g benzaldehyde were placed in a flask, under N 2 Under protection, stir and raise the temperature to 140°C, slowly add 1g p-toluenesulfonic acid, react for 4h; then raise the temperature to 180°C for 2h, cool to obtain the reacted mixture (phenolic resin and dephenolized oil). The reaction mixture was repeatedly washed with toluene as a solvent, the soluble part was incorporated into dephenolized oil, and the insoluble part was distilled off under reduced pressure at 80-90°C to obtain phenolic resin; the composition of the dephenolized oil was analyzed by gas chromatography-mass spectrometry , using infrared spectroscopy to analyze the phenolic resin.

[0046]

[0047] combine Figure 7 , Table 3 and Table 4, it was found that no phenolic compounds were found in the dephenolized oil after the fraction of middle and low temperature coal tar heavy oil >300°C reacted with benzald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com