A process and device for preparing phenolic resin from coal tar

A technology for phenolic resin and coal tar, applied in the processing of tar, refining tar by chemical method, petroleum industry and other directions, can solve the problems of increasing the difficulty of separation of phenolic resin, uneven phenolic resin, low utilization rate of coal tar, etc. More uniform and complete reaction, lower viscosity and lower hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

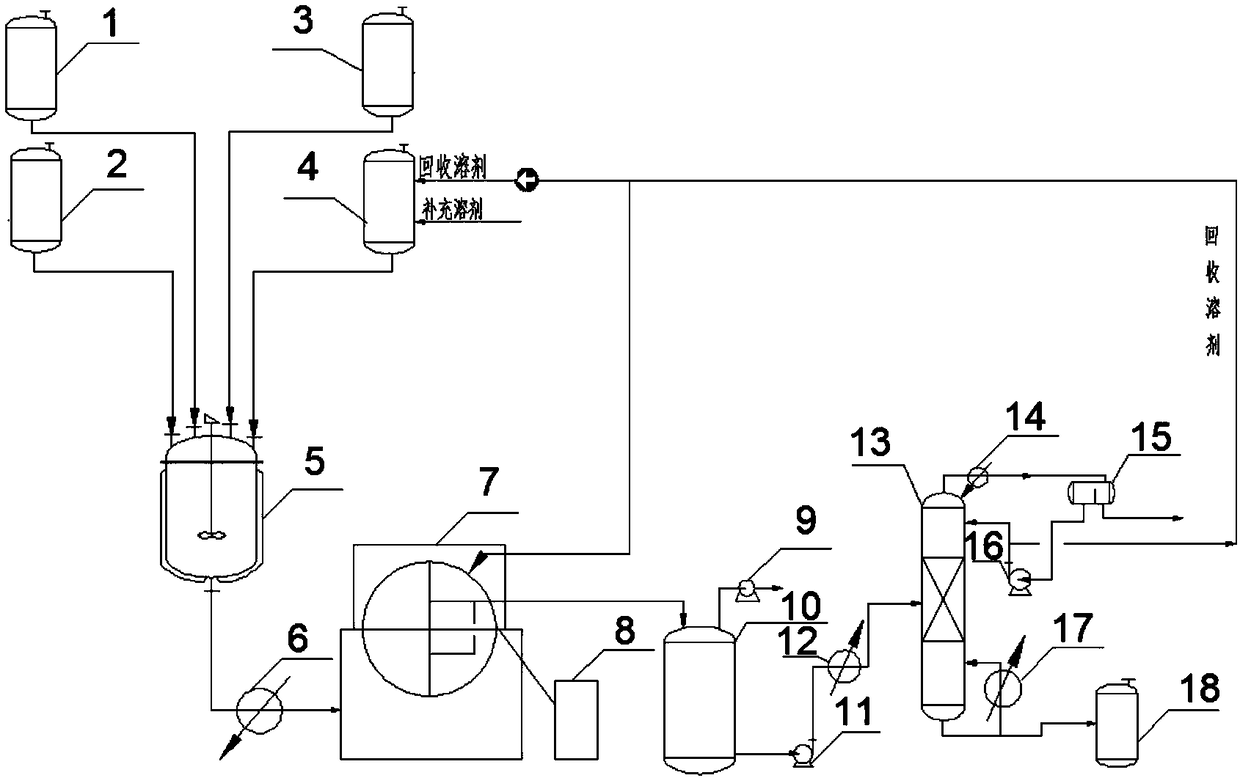

Method used

Image

Examples

Embodiment 1

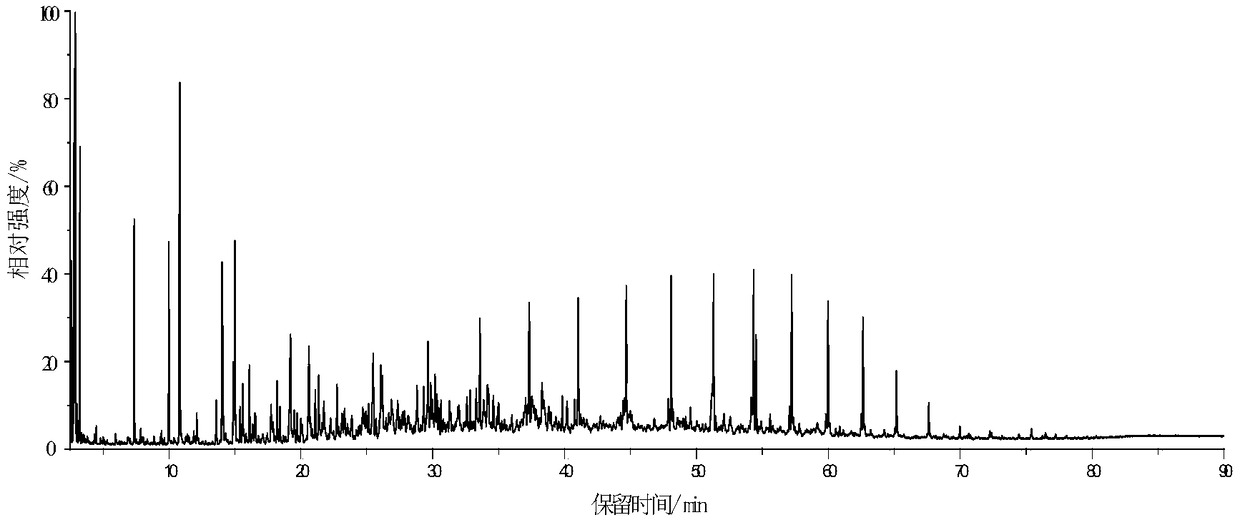

[0050] The method of heterogeneous polymerization is used for phenolic polymerization, using benzene or toluene as solvent, medium and low temperature coal tar as the raw material for phenol and aldehydes to react with aldehydes under the action of a catalyst to obtain dephenolized oil and phenolic resin, so as to achieve medium and low temperature Coal tar is used as raw material for the purpose of preparing phenolic resin. In order to illustrate the actual effect of the present invention, the components of medium and low temperature coal tar and dephenolized oil were determined by gas chromatography-mass spectrometry.

[0051] Select medium and low temperature coal tar heavy oil and formaldehyde solution (37wt%) as reactants, toluene as solvent, and concentrated sulfuric acid with a mass fraction of 98% as catalyst, wherein the mass ratio of medium and low temperature coal tar heavy oil to formaldehyde is 1:0.97, and medium and low temperature The mass ratio of coal tar heav...

Embodiment 2

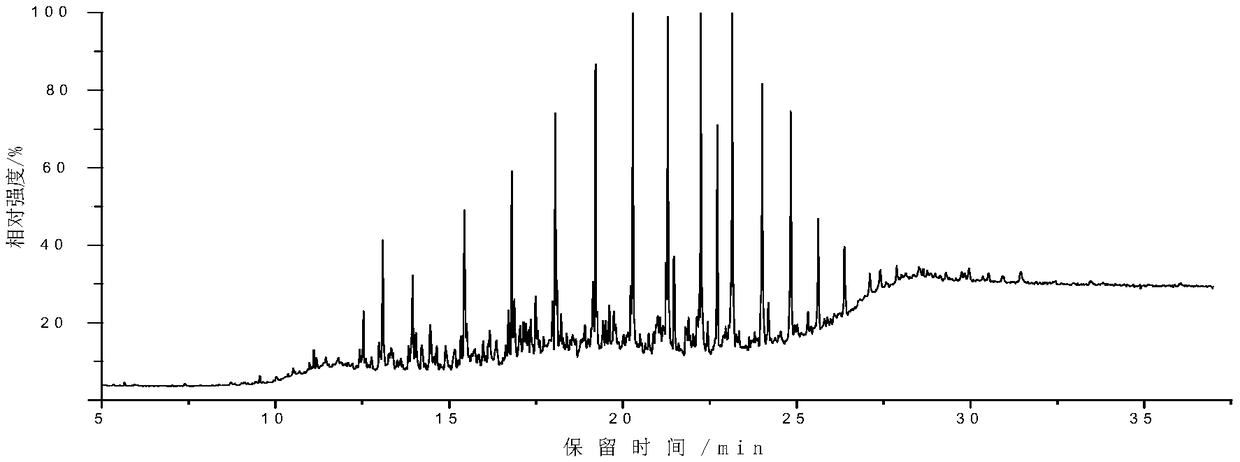

[0057] Choose medium and low temperature coal tar heavy oil > 300 ℃ distillate and formaldehyde solution (37wt%) as reactant, toluene is solvent, NaOH solution (40wt%) is catalyst, wherein, low temperature coal tar heavy oil > 300 ℃ distillate and formaldehyde The mass ratio of low-temperature coal tar heavy oil >300°C to solvent is 1:5, and the mass ratio of low-temperature coal tar heavy oil >300°C to catalyst is 1:0.18. The reaction temperature in the tar reactor 5 is 40-90° C., and the reaction time is 1.5-2 hours. After the above process was completed, the product (mainly dephenolized oil) was analyzed by gas chromatography-mass spectrometry, and the phenolic resin was analyzed by infrared spectroscopy, see Figure 4 , Figure 5 and Table 3.

[0058] In Table 3, the low-temperature coal tar heavy oil > 300 ° C fraction and its dephenolized oil (alkali-catalyzed) part of the composition table

[0059]

[0060] combine Figure 4 , Figure 5 From the results in Table...

Embodiment 3

[0062] Select medium and low temperature coal tar heavy oil >300°C fraction and benzaldehyde as reactants, toluene as solvent, and p-toluenesulfonic acid as catalyst, wherein the mass ratio of medium and low temperature coal tar heavy oil >300°C fraction to benzaldehyde is 1:1.2, The mass ratio of medium and low temperature coal tar heavy oil >300°C fraction to solvent is 1:10, the mass ratio of medium and low temperature coal tar heavy oil >300°C fraction to catalyst is 1:0.1, the reaction temperature is controlled at 140-180°C, and the reaction time is 4~6h. After the above process was completed, the product (mainly dephenolized oil) was analyzed by gas chromatography-mass spectrometry, see Figure 4 , Figure 7 , Table 2 and Table 4.

[0063] Partial composition of dephenolized oil (benzaldehyde, acid catalyzed) fraction of low temperature coal tar heavy oil >300°C in Table 4

[0064]

[0065] combine Figure 4 with Figure 7 , Table 3 and Table 4, it was found that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com