Trimming point calculation method based on binocular vision

A technology of binocular vision and calculation method, which is applied in the fields of calculation, image data processing, measurement device, etc., can solve the problems of low precision, inability to reach the detection accuracy of precision instruments, and inability to fully describe the geometric dimension characteristics of the space boundary.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

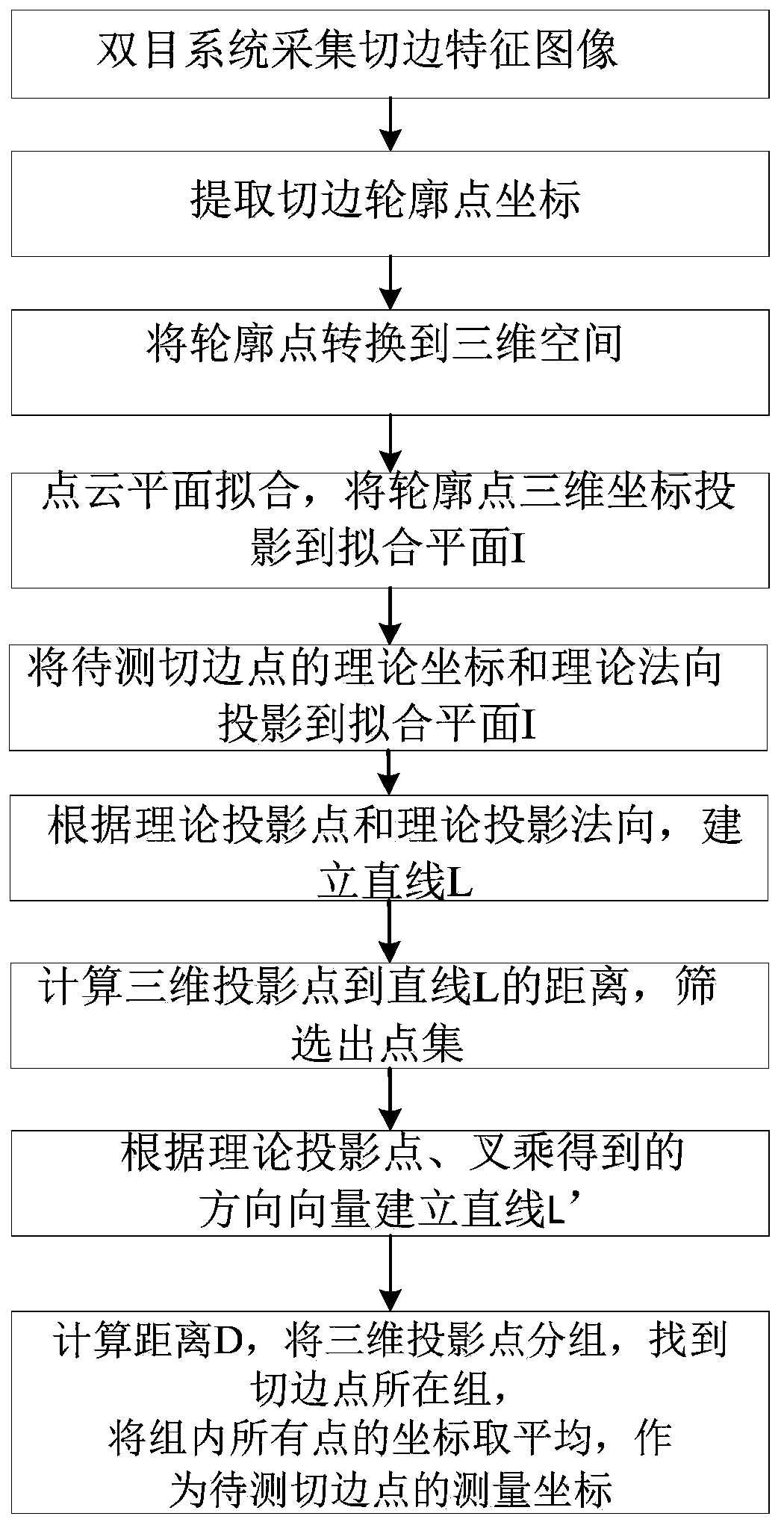

[0029] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] A method for calculating edge tangent points based on binocular vision, comprising the following steps:

[0031] 1) Use the binocular vision measurement system to collect the left and right grayscale images of the cut edge features;

[0032] 2) Perform image preprocessing such as Gaussian filtering, binarized images, and edge detection on the left and right images, and extract the two-dimensional point coordinates N of the trimmed contour edges of the left and right images t , t=1, 2, ... s; s is the number of two-dimensional points on the edge of the tangent contour;

[0033] 3) Using the epipolar line matching method to convert the trimming contour points in the left and right images to three-dimensional space, and obtain the three-dimensional point coordinate data of the trimming contour;

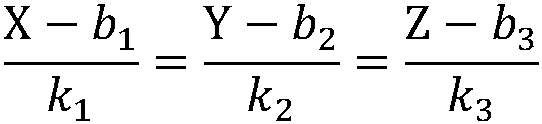

[0034] 4) Utilize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com