Optical cement for repairing touch screen cracks and application thereof

A touch screen, optical adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of unable to meet the high standard requirements of touch screen crack repair, and the degree of professional requirements is not high. Feasibility Strong, improved repair performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

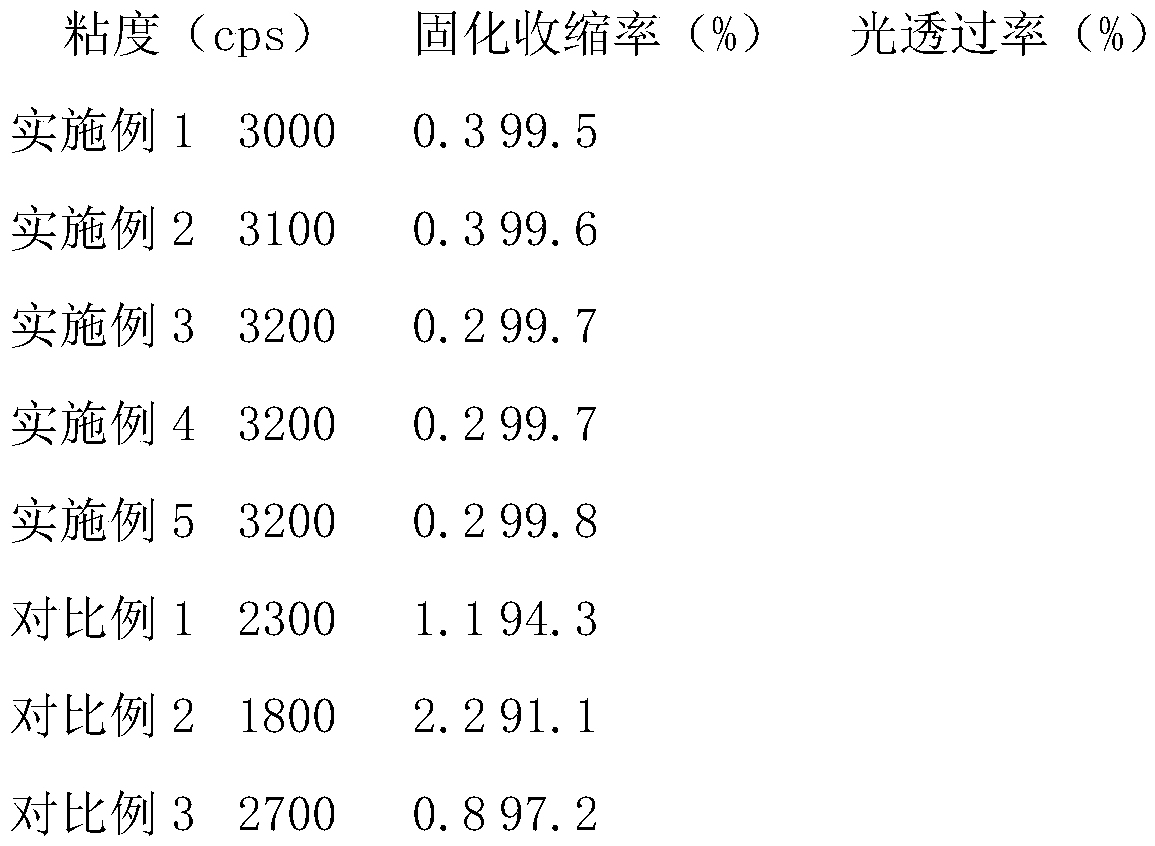

Examples

Embodiment 1

[0036] A preparation process of optical glue for touch screen crack repair, the specific steps are as follows:

[0037] (1) Under the condition of avoiding light, mix and stir the ultraviolet photoinitiator, glycidyl methacrylate, and ethoxylated trimethylolpropane triacrylate at a mass ratio of 1:5:7 to obtain the first mixture, which is set aside ;

[0038] (2) The emulsifier is added to 40 times the weight of deionized water, and mixed evenly to obtain a mixed solution;

[0039] (3) Silica hollow nanospheres are added to cyclohexane, ultrasonically oscillated for 10 minutes, acrylate and toluene diisocyanate are added, ultrasonically oscillated for 10 minutes, then added to the mixture obtained in step (2), and then slowly added in sequence Triethylene glycol diacrylate, polyether acrylate, tetrahydrofuran acrylate and isobornyl methacrylate were stirred at a speed of 800r / min for 25 minutes to obtain an emulsion;

[0040](4) Mix ethylene glycol dimethacrylate, polypropyl...

Embodiment 2

[0053] A preparation process of optical glue for touch screen crack repair, the specific steps are as follows:

[0054] (1) Under the condition of avoiding light, mix and stir the ultraviolet photoinitiator, glycidyl methacrylate, and ethoxylated trimethylolpropane triacrylate at a mass ratio of 1:6:8 to obtain the first mixture, which is set aside ;

[0055] (2) The emulsifier is added to 50 times the weight of deionized water, and mixed evenly to obtain a mixed solution;

[0056] (3) Silica hollow nanospheres are added to cyclohexane, ultrasonically oscillated for 15 minutes, acrylate and toluene diisocyanate are added, ultrasonically oscillated for 12 minutes, then added to the mixture obtained in step (2), and then slowly added in sequence Triethylene glycol diacrylate, polyether acrylate, tetrahydrofuran acrylate and isobornyl methacrylate were stirred at a speed of 1000r / min for 30 minutes to obtain an emulsion;

[0057] (4) Mix ethylene glycol dimethacrylate, polyprop...

Embodiment 3

[0070] A preparation process of optical glue for touch screen crack repair, the specific steps are as follows:

[0071] (1) Under the condition of avoiding light, mix and stir the ultraviolet photoinitiator, glycidyl methacrylate, and ethoxylated trimethylolpropane triacrylate at a mass ratio of 1:5:8 to obtain the first mixture, which is set aside ;

[0072] (2) The emulsifier is added to 40 times the weight of deionized water, and mixed evenly to obtain a mixed solution;

[0073] (3) Silica hollow nanospheres are added to cyclohexane, ultrasonically oscillated for 15 minutes, acrylate and toluene diisocyanate are added, ultrasonically oscillated for 10 minutes, then added to the mixture obtained in step (2), and then slowly added in sequence Triethylene glycol diacrylate, polyether acrylate, tetrahydrofuran acrylate and isobornyl methacrylate were stirred at a speed of 1000r / min for 25 minutes to obtain an emulsion;

[0074] (4) Mix ethylene glycol dimethacrylate, polyprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com