Strong field mode filter only with TM mode

A filter and mode technology, which is applied to waveguide devices, modified by conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problem of waveguide power capacity reduction, failure to meet low insertion loss electrical performance indicators, and increase system Problems such as the probability of ignition failure, to achieve the effect of high power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

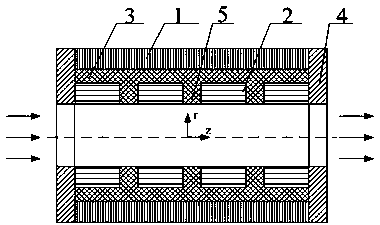

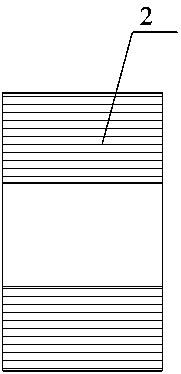

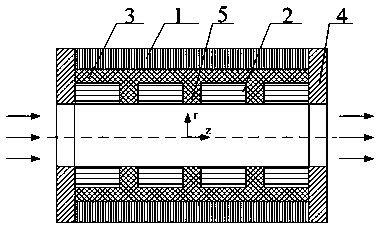

[0036] In the large bandwidth range of 27-42GHz, the insertion loss of TM01 mode and TM11 mode is less than 0.12dB, while the insertion loss of TE11 mixed mode field is greater than 0.5dB, and the insertion loss of TE21 mixed mode field is greater than 1.72dB. The schematic diagram of its structure is as follows figure 2 shown.

[0037] The device used in this example is highly oriented pyrolytic graphite with resistivity anisotropy, such as figure 1 As shown, the wall thickness in the r direction is 2mm, and the length in the z direction is 200mm; the resistivity in the z direction is 3.5~4.5×10 -7 Ω.m, close to 2.22×10 of platinum metal -7 Ω.m, with good electrical conductivity; the resistivity in the angular direction is 1.5~2.5×10 -3 Ω.m, which can effectively attenuate the wall current; the thermal conductivity in the Z direction is 1600-2000W / m.k, which is much higher than the 200W / m.k of duralumin. The material can work at high temperature, the hardest at 2750°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com