N-doped porous carbon-coated Co3O4 composite nano material and preparation method thereof, and application of N-doped porous carbon-coated Co3O4 composite nano material

A technology of nitrogen-doped porous carbon and composite nanomaterials, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that hinder the commercial application of composite nanomaterials, time-consuming, complex processes, etc. problems, achieve good cycle stability, simple and efficient process, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This implementation discloses a nitrogen-doped porous carbon-coated Co 3 o 4 Composite nanomaterials, comprising the following steps of preparation:

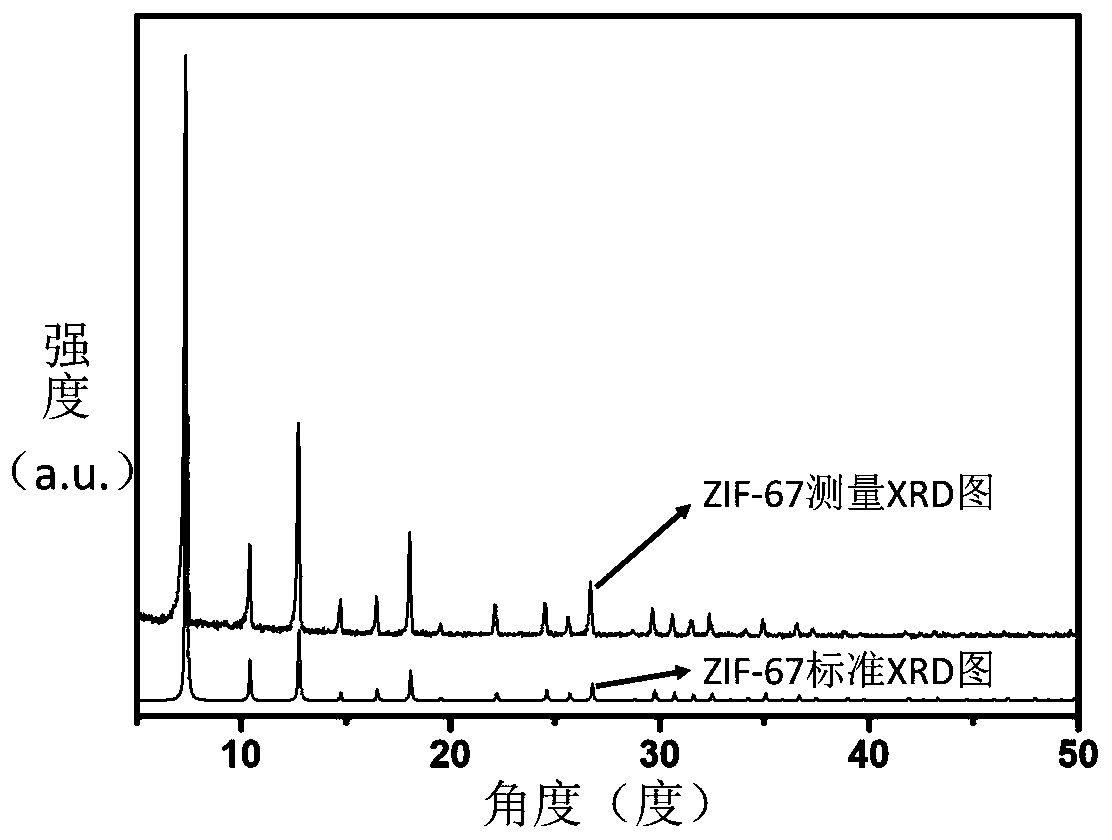

[0053] (1) At room temperature, 249mg of cobalt nitrate and 328mg of 2-methylimidazole were dissolved in 25mL of methanol respectively, the two solutions were mixed together, the mixture was stirred for 5min, and left to stand at room temperature for 24h; centrifuged to prepare The sample was washed three times with methanol, and then dried in an oven at 60 °C for 6 h to obtain a purple precursor.

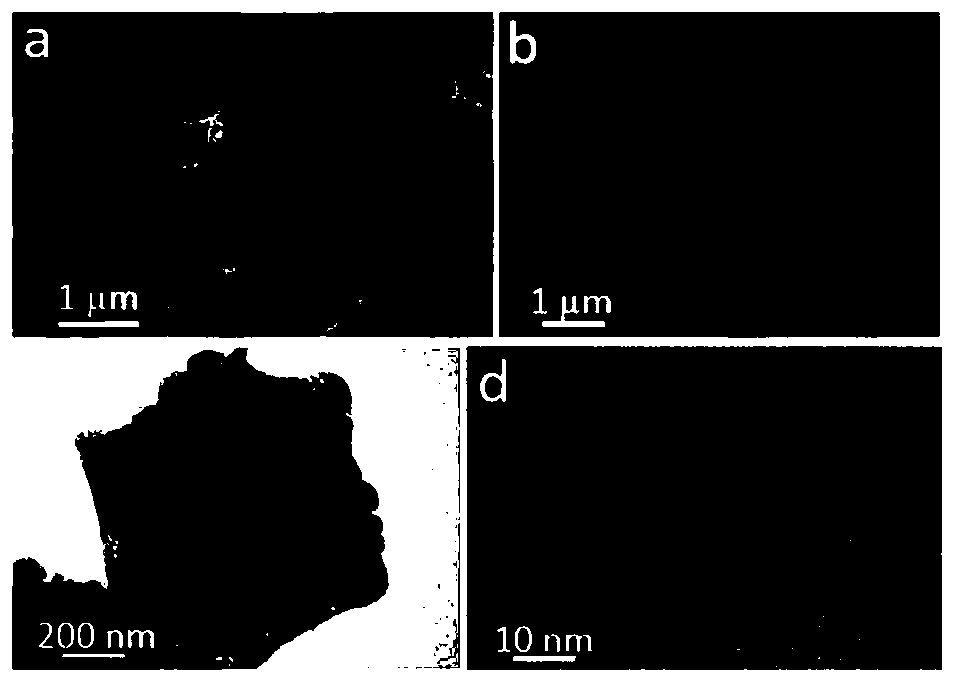

[0054] (2) The initial temperature of the prepared precursor was 50°C in a nitrogen atmosphere, and the temperature was raised to 600°C at a heating rate of 10°C / min, and then carbonized for 2 hours to obtain nitrogen-doped carbon-coated metal cobalt.

[0055] (3) 25 mg of nitrogen-doped porous carbon-coated cobalt composite nanomaterials were ultrasonically dispersed into 30 mL of deionized water, and then 2 mL of H 2 o 2...

Embodiment 2

[0064] This example discloses a porous carbon-coated Co prepared in Doping Example 1. 3 o 4 Application of composite nanomaterials in lithium-ion battery anodes.

[0065] Coating the obtained doped porous carbon with Co 3 o 4 Composite nanomaterials, acetylene black, and polyvinylidene fluoride PVDF are mixed at a mass ratio of 8:10:10 to form a slurry, and the slurry is evenly coated on the copper foil, and after drying in an oven at 80°C, Cut the copper foil into a circular electrode sheet with a diameter of 14mm; use the doped porous carbon to coat the Co 3 o 4 The circular electrode sheet of the composite nanomaterial is the positive electrode, and the circular metal lithium sheet with a diameter of 14mm is the negative electrode, which is composed of ethylene carbonate EC and diethyl carbonate DEC mixed in a mass ratio of 1:1, with a concentration of 1mol / L lithium hexafluorophosphate LiPF 6 The mixed solution was used as the electrolyte, and a circular polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com