Salt-free dyeing method of cationic ion modified cotton fabric

A salt-free dyeing technology for cotton fabrics, applied in the direction of dyeing, textile and papermaking, etc., can solve the problems of poor levelness, reduced color fastness, darkening of color light, etc., and achieves high color fastness and good wet rubbing fastness. , the effect of color light not dimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Prepare modified treatment solution at room temperature (N-methylolacrylamide (NMA) 10g / L, pH value 8, liquor ratio 1:8) → cotton fabric at 45°C, soak for 45min → 120°C, bake for 2min → cold water Wash and tumble dry.

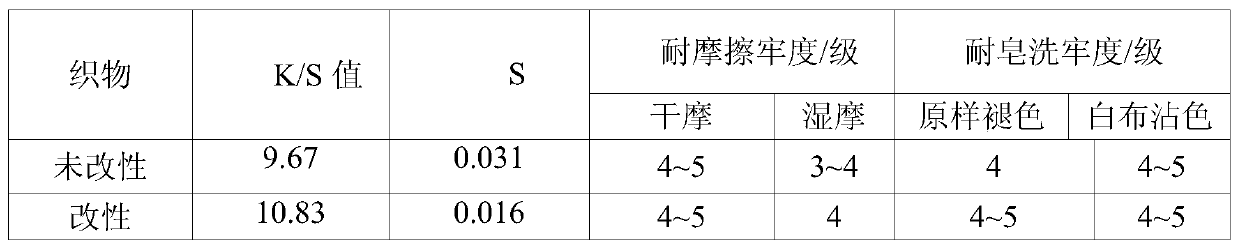

[0029] Dyeing of modified cotton fabric at room temperature (acid reactive red RC-3B 2% (OWF), liquor ratio 1:10) → heating up to 95°C at a speed of 1°C / min, keeping it warm for 45min → cooling down to 70°C, adding color fixing agent G701 2% (OWF), color fixation for 30min→water washing→soaping (soap flakes 2g / L, 95℃, 10min, bath ratio 1:10)→water washing→drying. Determination of apparent depth K / S value, unevenness S and color fastness, the results are shown in Table 1.

[0030] Table 1

[0031]

Embodiment 2

[0033] Prepare modified treatment solution at room temperature (N-dimethylazetidine chloride (DMAC) 15g / L, pH value 5, liquor ratio 1:10) → viscose fabric at 50°C, soak for 30min → 130°C , bake for 2min→wash in cold water and dry.

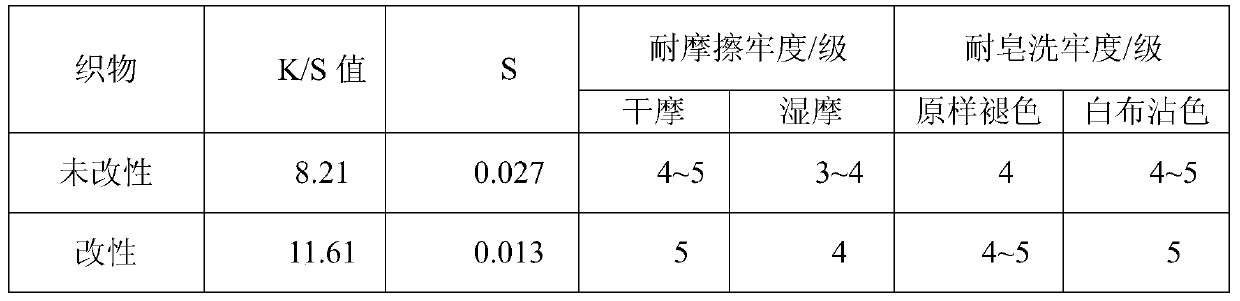

[0034] Dyeing of viscose fabric at room temperature (acid reactive dye yellow RC-3R 2% (OWF), liquor ratio 1:15) → heat up to 95°C at a speed of 1°C / min, keep warm for 60min → cool down to 65°C, add color fixing agent WS 2% (OWF), fix color for 30min→water washing→soaping (soap flakes 2g / L, 95℃, 15min, liquor ratio 1:10)→water washing→drying. Determination of apparent depth K / S value, unevenness S and color fastness, the results are shown in Table 2.

[0035] Table 2

[0036]

Embodiment 3

[0038] Prepare modified treatment solution at room temperature (N-methylolacrylamide (NMA) 15g / L, pH value 8, liquor ratio 1:10) → viscose fabric at 50°C, soak for 40min → 120°C, bake for 2.5min →Wash in cold water and tumble dry.

[0039] Dyeing of viscose fabric at room temperature (acid reactive dye blue RC-R 2% (OWF), bath ratio 1:15) → heat up to 95°C at a speed of 1°C / min, keep warm for 40min → cool down to 70°C, add color fixing agent DK 2% (OWF), fix color for 30min→water washing→soaping (soap flakes 2g / L, 100℃, 10min, liquor ratio 1:10)→water washing→drying. Determination of apparent depth K / S value, unevenness S and color fastness, the results are shown in Table 3.

[0040] table 3

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com