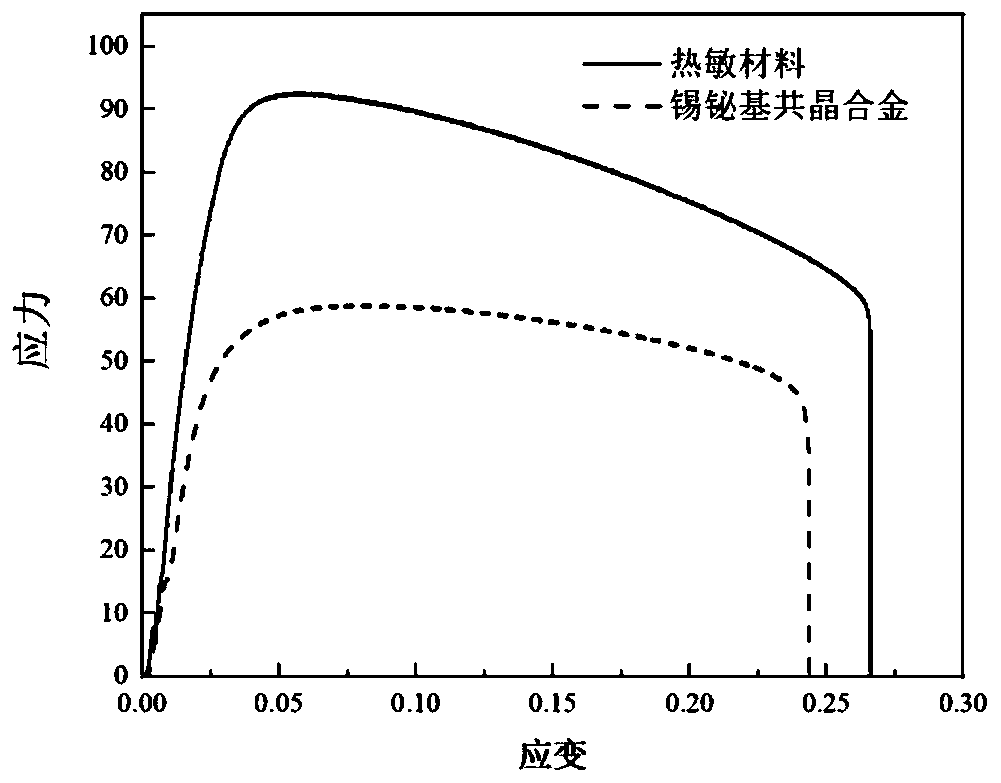

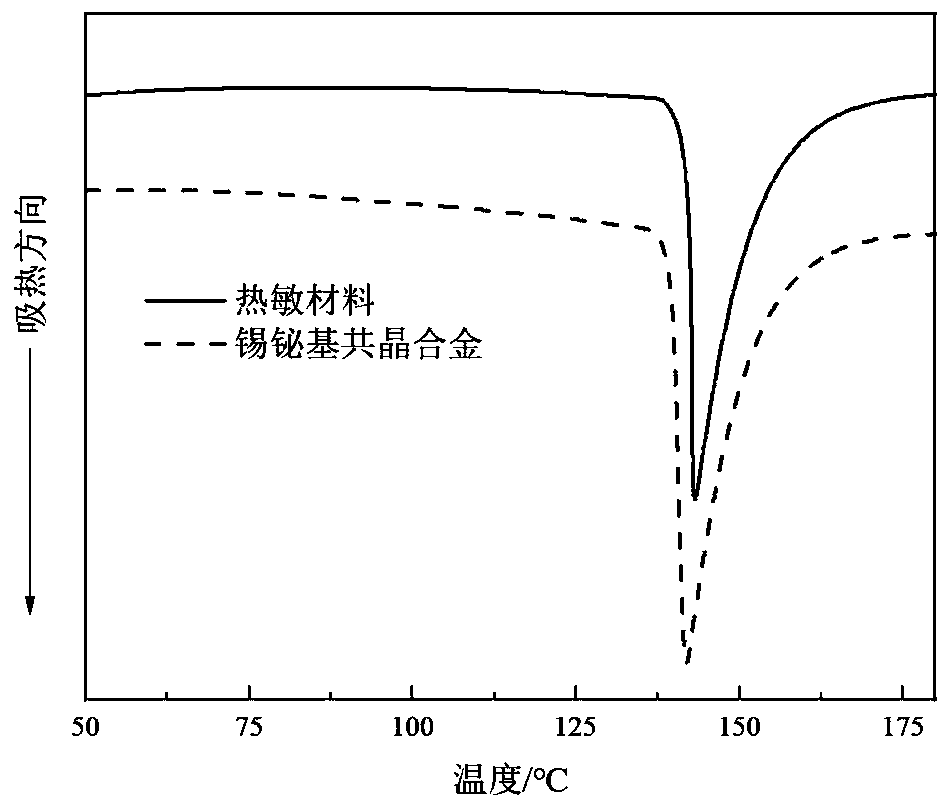

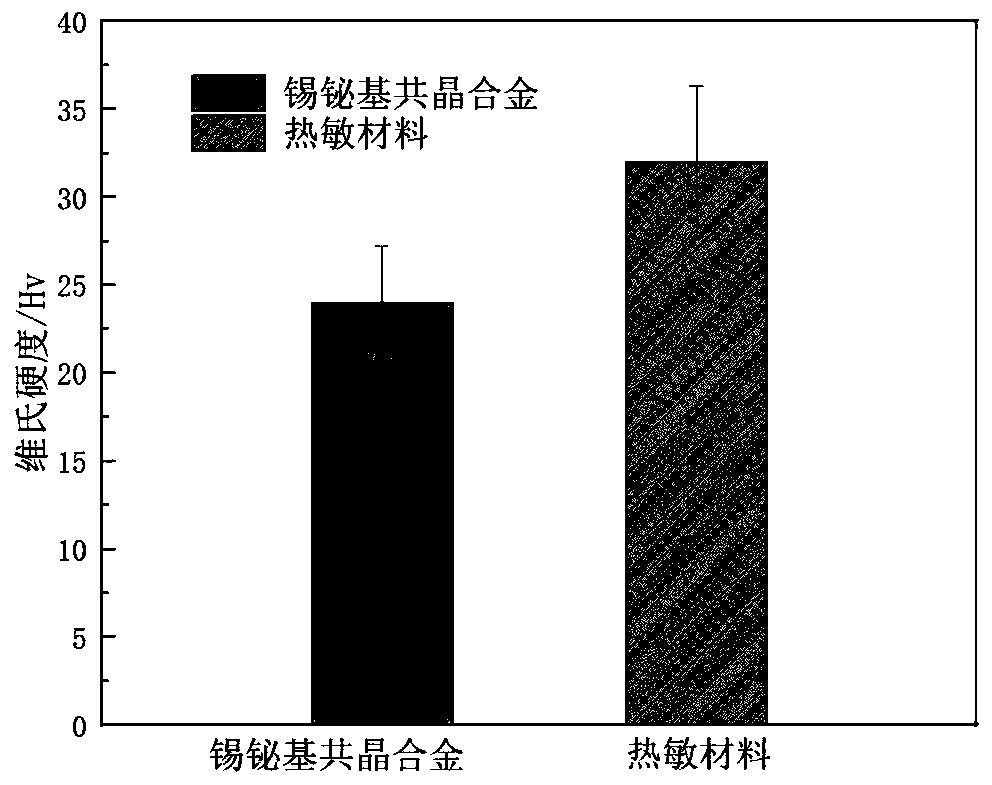

Low-melting-point and high-strength heat-sensitive material and preparation method thereof

A heat-sensitive material and high-strength technology, used in metal processing equipment, transportation and packaging, etc., can solve problems such as temperature rise and pressure expansion, and achieve the effect of simple process, improved service life and reduced use cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029](1) Select tin powder, bismuth powder, silver powder with a mass of 10.44g, 14.41g, 0.125g and 0.025g with a purity of 99.99% and a hydrophilic anatase titanium dioxide powder with a particle size of 5-10 nanometers. Mechanical stirring was carried out in a high-purity argon vacuum glove box for 1 hour to obtain 25 g of mixed powder.

[0030] (2) Choose 20g, 40g and 140g of zirconia grinding balls with three sizes of large, medium and small with diameters of 15mm, 10mm and 8.5mm respectively.

[0031] (3) Put 25g of mixed powder and zirconia grinding balls of large, medium and small sizes into a cylindrical nylon ball mill with a diameter of 8cm and a height of 10cm and add 50ml of analytically pure toluene solution into it.

[0032] (4) Immerse the ball mill jar in liquid nitrogen for 3 hours, vacuumize the jar body, fill with high-purity argon gas, wash off the vacuum, thaw at room temperature, and repeat the above steps 3 times.

Embodiment 2

[0041] (1) Select 8.25g, 11.40g, 0.30g and 0.05g of tin powder, bismuth powder, silver powder with a purity of 99.99% and hydrophilic anatase titanium dioxide powder with a particle size of 5-10 nanometers respectively. The mixture was mechanically stirred and mixed in an argon vacuum glove box, and stirred for 1 hour to obtain 20 g of mixed powder.

[0042] (2) Choose 20g, 35g and 112g of zirconia grinding balls with three sizes of large, medium and small with diameters of 15mm, 10mm and 8.5mm respectively.

[0043] (3) Put 20g of mixed powder and zirconia grinding balls of large, medium and small sizes into a cylindrical nylon ball mill with a diameter of 8cm and a height of 10cm and add 40ml of analytically pure toluene solution into it.

[0044] (4) Same as Example 1(4).

[0045] (5) Put the ball mill jar into the planetary ball mill, set the speed to 125rpm / min, rotate clockwise for 30 minutes and let it stand for 5 minutes, then rotate counterclockwise for 30 minutes an...

Embodiment 3

[0050] (1) 10.34g, 14.28g, 0.25g and 0.125g of tin powder, bismuth powder, silver powder with a purity of 99.99% and hydrophilic anatase titanium dioxide powder with a particle size of 5-10 nanometers were selected respectively. The mixture was mechanically stirred and mixed in an argon vacuum glove box, and stirred for 1 hour to obtain 20 g of mixed powder.

[0051] (2) Choose 20g, 40g and 140g of zirconia grinding balls with three sizes of large, medium and small with diameters of 15mm, 10mm and 8.5mm respectively.

[0052] (3) Put 25g of mixed powder and zirconia grinding balls of large, medium and small sizes into a cylindrical nylon ball mill with a diameter of 8cm and a height of 10cm and add 40ml of analytically pure toluene solution into it.

[0053] (4) Same as Example 1(4).

[0054] (5) Put the ball mill into the planetary ball mill, set the rotational speed to 140rpm / min, rotate clockwise for 30 minutes and then let it stand for 5 minutes, then rotate counterclockw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com