Metal-organic framework nanomaterial loaded with ZnPc as well as preparation method and application of metal-organic framework nanomaterial

A metal-organic framework and metal framework material technology, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, wave energy or particle radiation treatment materials, etc., can solve the problems of easy agglomeration and poor stability, etc. To achieve the effect of mild reaction temperature, simple reaction steps and convenient industrial scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

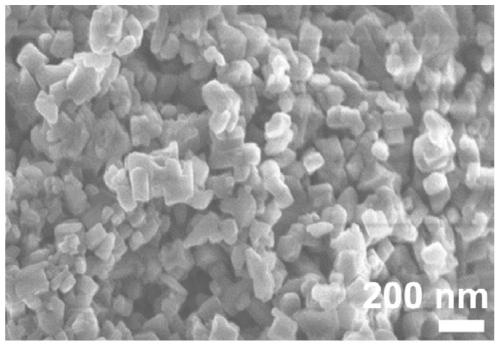

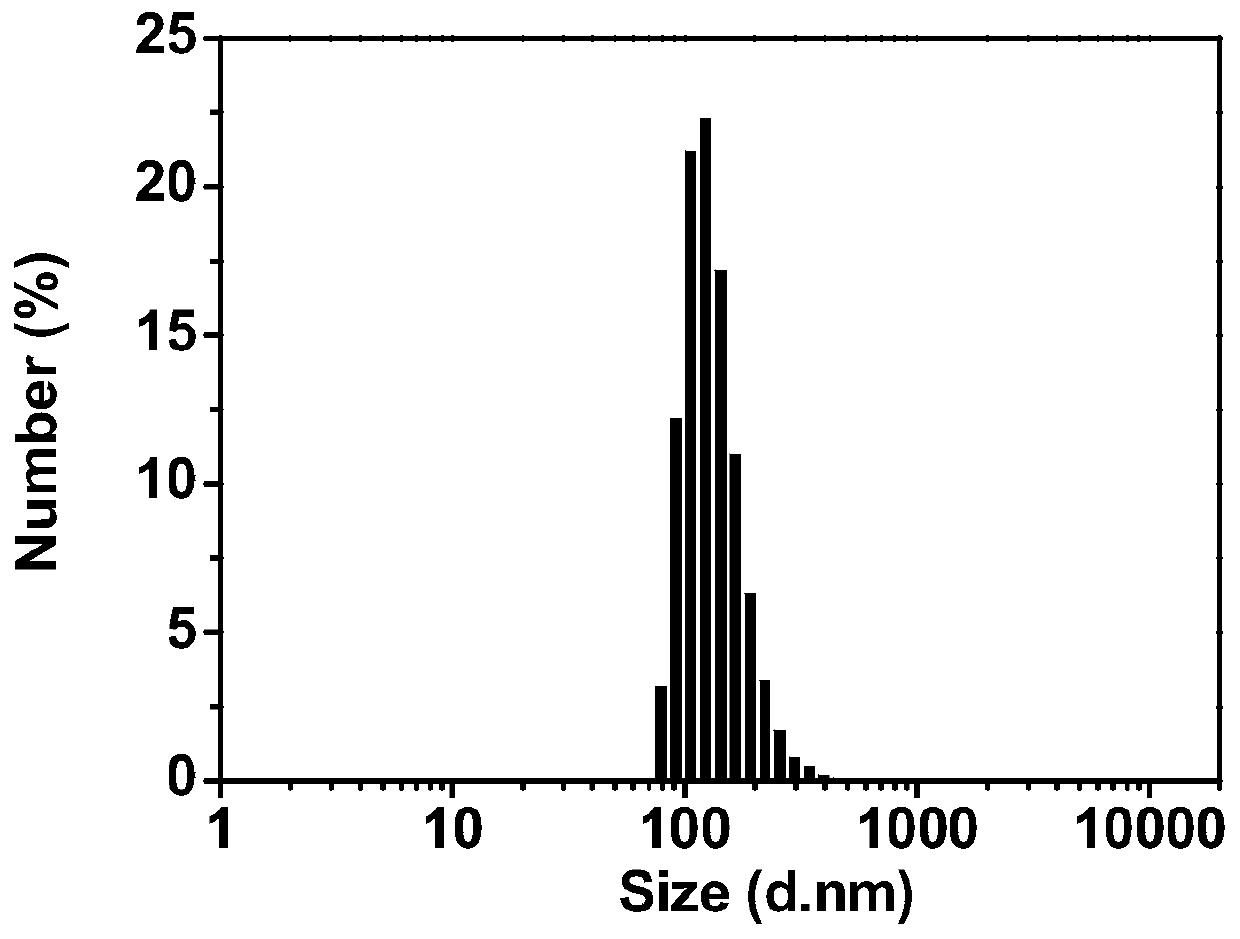

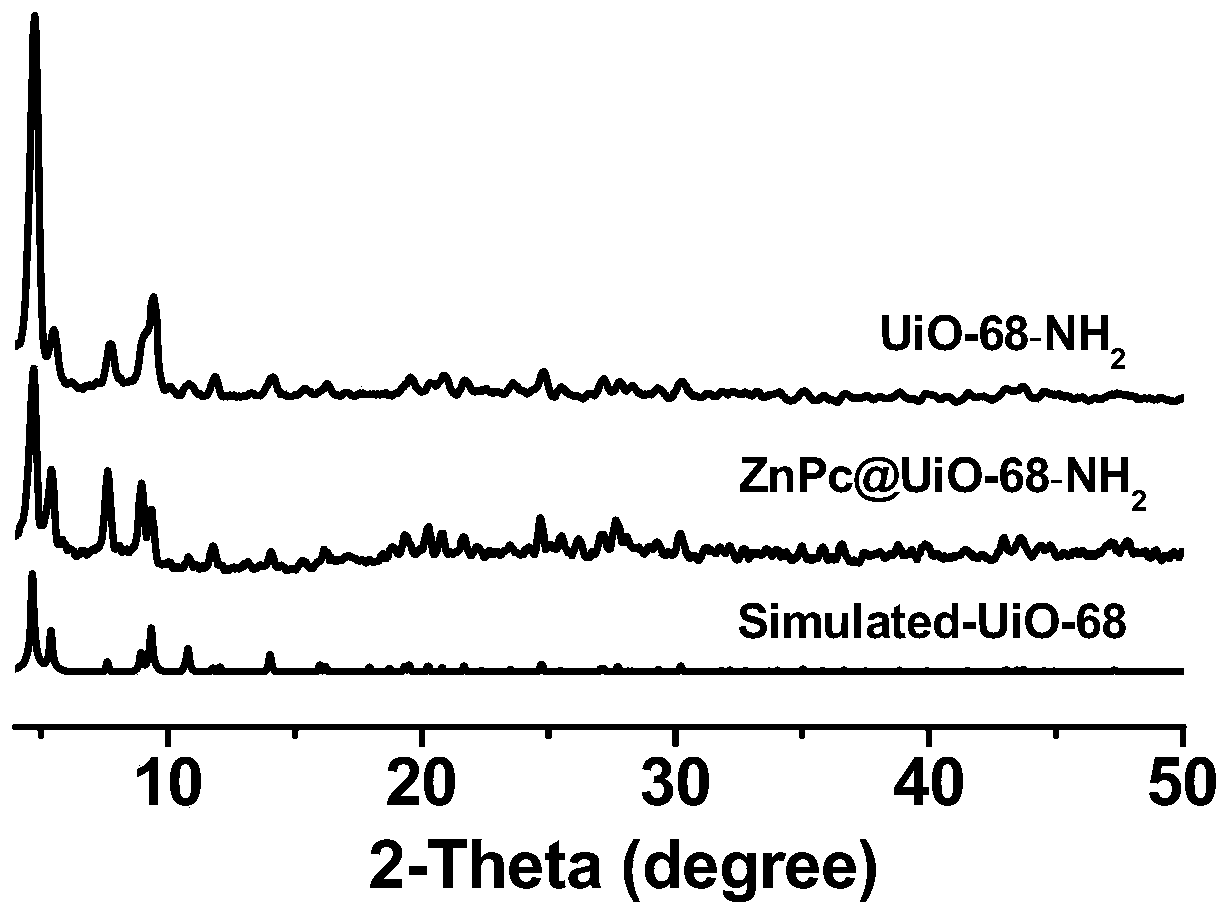

[0031] In yet another specific embodiment of the present invention, the preparation method includes: ZrCl 4 Add to DMF (N,N-dimethylformamide), then add acetic acid, 2,5-bis(4'-carboxyphenyl)aniline to dissolve, and finally add zinc phthalocyanine, disperse evenly and synthesize by solvothermal method The reaction product A was obtained, and the dark green powder obtained after purification was ZnPc@UiO-68-NH 2 nanomaterials.

[0032] In yet another specific embodiment of the present invention, a kind of preparation method of 2,5-di(4'-carboxyphenyl)aniline is provided, and the preparation method comprises:

[0033](1) Vacuumize 2,5-dibromoaniline, 4-methoxycarbonylphenylboronic acid, cesium fluoride and palladium catalyst, then add tetrahydrofuran, heat and react to obtain light yellow product Me 2 -L;

[0034] (2) To the pale yellow product Me 2 -L is added potassium hydroxide solution, tetrahydrofuran and water, reacted at room temperature and then distilled tetrahydrof...

Embodiment 1

[0050] Synthesis of 2,5-bis(4'-carboxyphenyl)aniline (H 2 -L):

[0051] 2,5-dibromoaniline (10mmol, 2.51g), 4-methoxycarbonylphenylboronic acid (30mmol, 5.4g), cesium fluoride (47.5mmol, 7.22g) and palladium catalyst (3.3mmol, 3.8g) were extracted In vacuum, 150 mL redistilled tetrahydrofuran was added and reacted at 80° C. for 48 h. The obtained product was subjected to suspension steaming, washed with water, and dried. The product was first purified with dichloromethane as the eluting agent through a chromatographic column to obtain a light yellow product Me 2 -L (2.1g, yield: 58.3%). 1 HNMR (400MHz, DMSO-d 6 ,ppm):8.05-8.03(d,4H,-C 6 h 4 -),7.78-7.76(d,2H,-C 6 h 4 -),7.65-7.63(d,2H,-C 6 h 4 -),7.16(d,2H,-C 6 h 3 -),7.03-7.01(d,1H,-C 6 h 3 -),5.15(s,2H,-NH 2 ),3.88(s,6H,-CH 3 ). ESI-MS: m / z Calcd for C 22 h 19 NO 4 [M+H] + 362.1394; Found 362.1392.

[0052] Take Me 2 -L (2.0mmol, 724mg) in a 250mL reaction flask, add 1.5mL 10M potassium hydroxide soluti...

Embodiment 2

[0054] Metal Organic Framework Nanomaterial UiO-68-NH 2 Preparation of:

[0055] Weigh ZrCl 4 (19mg, 0.08mmol) was added to 3.2mL DMF, ultrasonically dispersed, then 240μL acetic acid was added for ultrasonically dispersed, and finally p-2,5-bis(4'-carboxyphenyl)aniline (H 2 -L) (28 mg, 0.08 mmol), sonicate to dissolve completely. Keep the temperature at 90°C for 48h, cool down to room temperature after 2h, and centrifuge at a high speed to obtain a solid, immerse the solid in DMF, stir and soak at 80°C for 6h, and centrifuge at a high speed. Then immerse the solid in absolute ethanol, stir and soak for 6 hours at 70° C., and centrifuge at a high speed to obtain solid powder. This operation was repeated 3 times. Finally, the solid was washed with ether and dried naturally to obtain a light yellow powder UiO-68-NH 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com