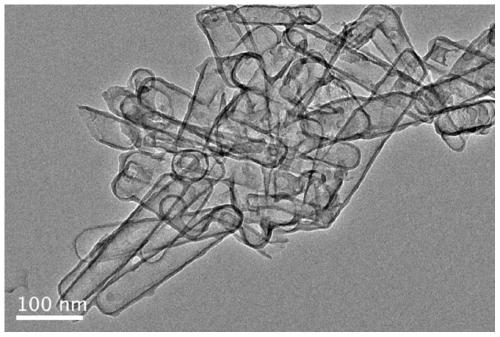

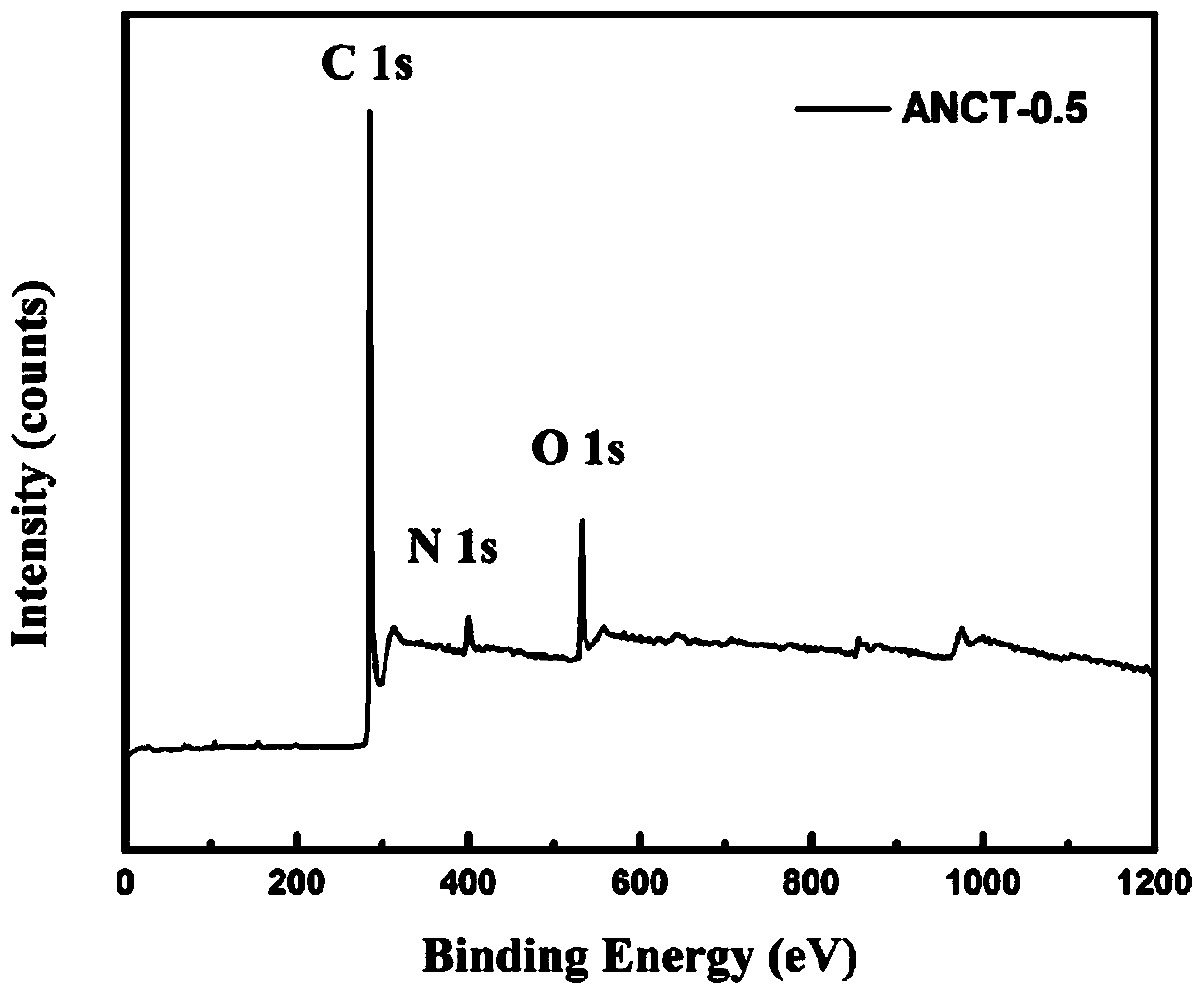

Preparation method of hollow nitrogen-doped carbon nanotubes

A technology of nitrogen-doped carbon and nanotubes, applied in carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of expensive raw materials, difficult preparation, high cost, etc., and achieve high aspect ratio and excellent morphology stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Synthesis of nickel hydrazine@SiO 2 @APF Composites

[0038] With 8.5g nonionic surfactant Brij 58 (C 16 E. 20 ) was dissolved in 15 mL of cyclohexane and kept in a constant temperature water bath at 50°C. With stirring, 1.9 mL of nickel chloride (NiCl 2 ) solution (0.8mol / L) and stirred until uniform, then added dropwise 0.45mL hydrazine hydrate. After stirring for 3 hours, 1 mL of triethylamine and 3 mL of tetraethylorthosilicate (TEOS) were continuously added to the system. The silica coating process was carried out for 12 hours under magnetic stirring and cooled. The liquid after reaction was centrifuged and washed 3 times with isopropanol, 5mL isopropanol, 0.5mL diethylamine solution, 0.5g 3-aminophenol and 0.7mL formaldehyde were added, and stirred at room temperature for 24 hours, the obtained solid was Nickel Hydrazine@SiO 2 @APF composites.

[0039] (2) Carbonization. The dried nickel hydrazine@SiO 2 The @APF composite was calcined in a tube furna...

Embodiment 2

[0044] Other reaction conditions are with embodiment 1, nickel chloride (NiCl 2 ) solution becomes 1.7 mL in volume.

Embodiment 3

[0046] Other reaction conditions are with embodiment 1, nickel chloride (NiCl 2 ) The volume of the solution becomes 1.5 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com