Lithium ion battery, and aluminum-plastic film

A lithium-ion battery and aluminum-plastic film technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of poor airtightness of packaging, corrosion of packaging, easy scratches, etc., and achieve strong heat resistance and safety High performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

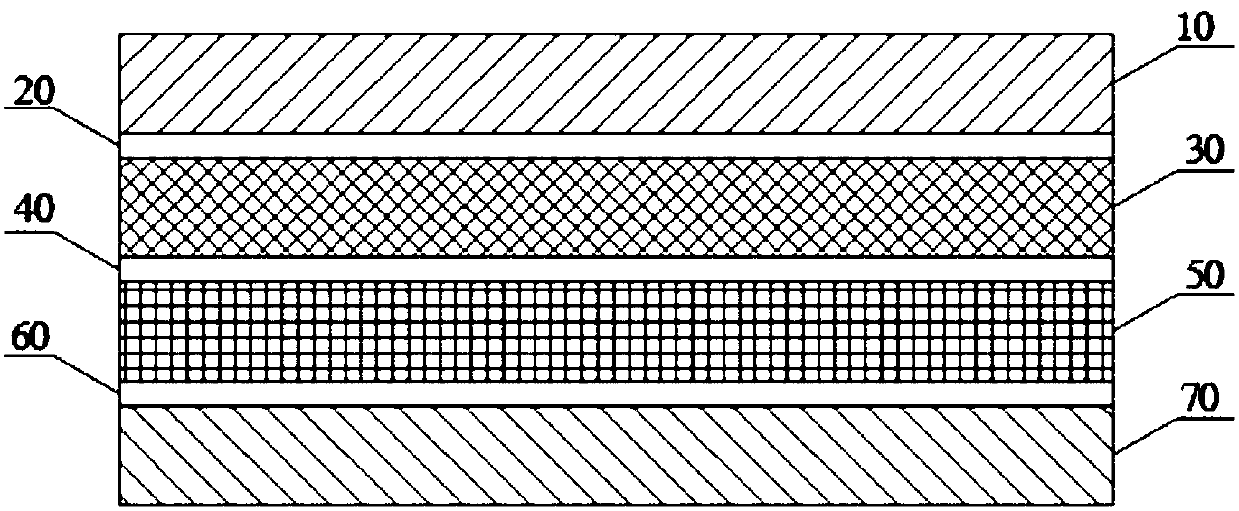

Image

Examples

Embodiment 1

[0026] 1) Preparation of negative electrode sheet

[0027] Negative electrode active material artificial graphite, carbon black conductive agent SP, binder styrene-butadiene rubber, thickener CMC (carboxymethyl cellulose) are mixed according to weight ratio 96.2:1.5:1.5:0.8, add solvent deionized water, Stir and mix evenly under vacuum conditions to obtain the negative electrode slurry; evenly coat the negative electrode slurry on the copper foil of the negative electrode current collector, and then dry it at 80-90°C for cold pressing, trimming, cutting, and stripping , and then dried at 110° C. under vacuum for 4 hours to obtain a negative electrode sheet.

[0028] 2) Preparation of positive electrode sheet

[0029] The cathode active material LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 (NCM333), carbon black conductive agent SP, and binder polyvinylidene fluoride are mixed according to a weight ratio of 97:2:1, and solvent N-methyl pyrrolidone is added, stirred and mixed evenly under va...

Embodiment 2

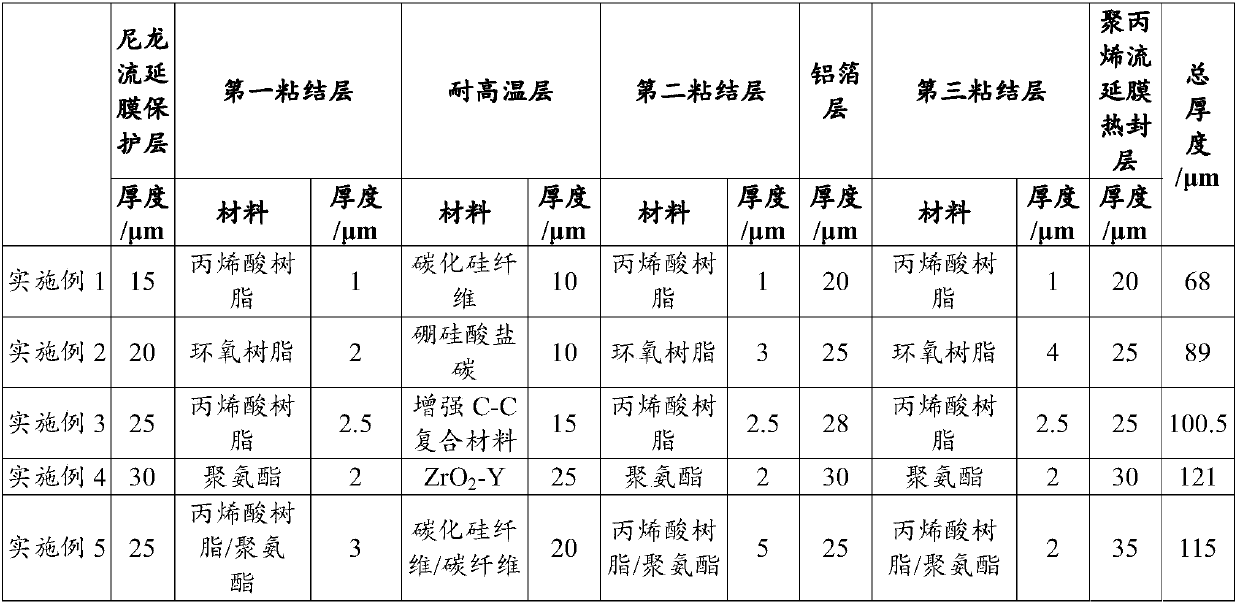

[0036] The thickness of the nylon cast film protective layer is 20 μm, the material of the first bonding layer is epoxy resin, the thickness is 2 μm, the material of the high temperature resistant layer is borosilicate carbon, the thickness is 10 μm, and the material of the second bonding layer is epoxy resin , the thickness is 3 μm, the thickness of the aluminum foil layer is 25 μm, the material of the third bonding layer is epoxy resin, the thickness is 4 μm, the thickness of the polypropylene cast film heat seal layer is 25 μm, and the total thickness of the aluminum-plastic film is 89 μm.

Embodiment 3

[0038] The thickness of the protective layer of the nylon cast film is 25 μm, the material of the first adhesive layer is acrylic resin, the thickness is 2.5 μm, the material of the high temperature resistant layer is reinforced C-C composite material, the thickness is 15 μm, the material of the second adhesive layer is acrylic resin, the thickness is The thickness of the aluminum foil layer is 2.5 μm, the thickness of the third bonding layer is acrylic resin, the thickness is 2.5 μm, the thickness of the heat-sealing layer of the polypropylene cast film is 25 μm, and the total thickness of the aluminum-plastic film is 100.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com