Method used for post-treatment of on-pot in-situ synthesized Cu-SSZ-13 molecular sieve

A cu-ssz-13, in-situ synthesis technology, applied in the chemical field, can solve the problems of unfavorable large-scale industrial production, high requirements for processing equipment, and increased production costs, and achieve excellent anti-metal poisoning ability and low requirements for reaction equipment , The effect of a complete skeleton structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The Cu-SSZ-13 molecular sieve synthesized in situ by the one-pot method is post-treated to prepare the Cu-SSZ-13 catalyst by adopting the method provided by the invention:

[0018] Prepare a sodium hydroxide solution with a pH of 9, add Cu-SSZ-13 molecular sieves synthesized in situ by a one-pot method calcined at 600°C to the above sodium hydroxide solution, and stir at room temperature at 25°C for 12 hours, then use Washed with distilled water for 3 times, and finally dried at 100°C for 12 hours to obtain the final Cu-SSZ-13 catalyst.

Embodiment 2

[0020] The evaluation of Cu-SSZ-13 catalyst adopts the following methods:

[0021] Mix 2g of catalyst powder with an appropriate amount of water to prepare a slurry, and coat it on a small sample of cordierite honeycomb ceramic substrate. The coating amount of the slurry prepared by catalyst powder is about 250g L -1 The monolithic Cu-LTA catalyst was prepared after the sample was dried at 100°C for 2 hours. It was put into a fixed bed activity evaluation device, and the simulated flue gas composition was 1000ppm NO, 1100ppm NH 3 ,5%O 2 and 10%H 2 O, the reaction space velocity is 30,000h -1 .

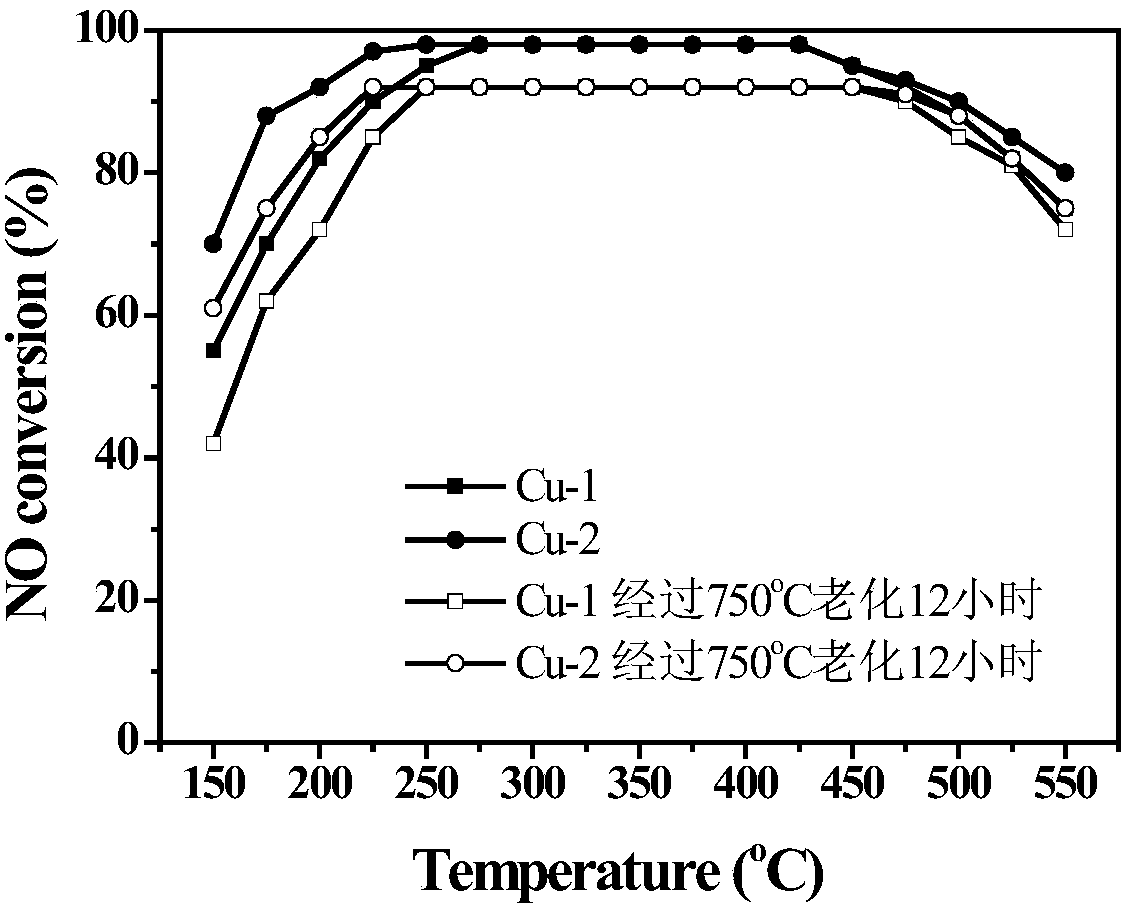

[0022] The hydrothermal aging of the catalyst adopts the following method:

[0023] Put the monolithic catalyst into the aging device, raise the temperature to 750°C at a rate of 10°C / min, and let air and 10% water vapor flow in, and maintain this temperature for 12 hours.

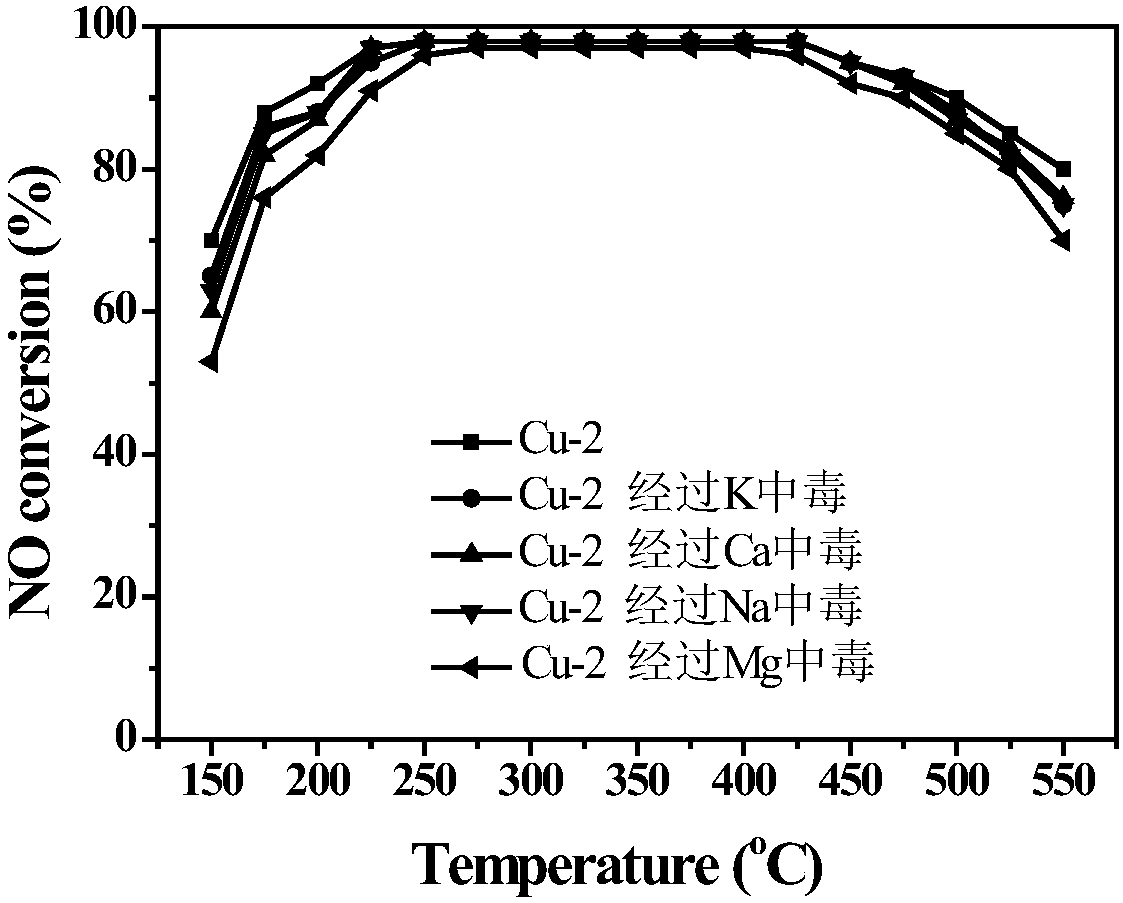

[0024] Catalyst metal poisoning by the following methods:

[0025] Put the catalyst (Cu-2) catalyst obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com