Preparation method of thin film and QLED device

A thin film and nanoparticle technology, applied in the field of thin film preparation, can solve the problem of less composite materials, achieve the effect of balancing electrons and holes, enhancing luminous efficiency, and improving electron transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

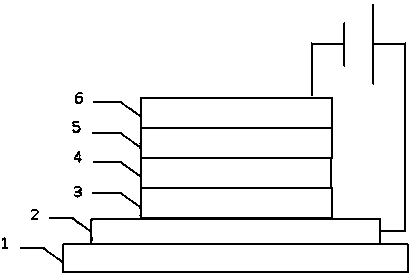

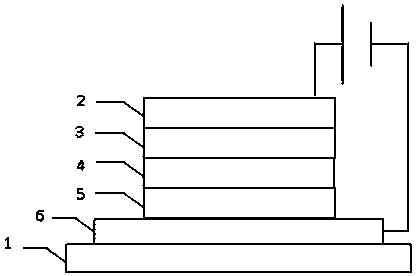

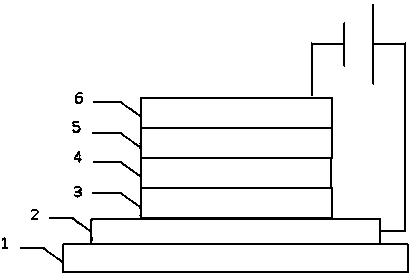

Image

Examples

Embodiment 1

[0050] The following is to prepare ZnO / TiO by using zinc acetate, titanium sulfate, ethanol, potassium hydroxide, and ethyl acetate 2 Films composed of core-shell nanoparticles are described in detail.

[0051] (1) First, add an appropriate amount of zinc acetate to 50mL of ethanol to form a solution with a total concentration of 0.5M. Then stir and dissolve at 60°C, add lye (prepared by dissolving potassium hydroxide in 10mL ethanol), and the dissolved OH in the solution is - : Zn 2+ =2.0:1. Stirring was continued at 60 °C for 3 h to obtain a homogeneous clear solution. Subsequently, after the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of ethanol (repeated operation, washed 3 times) to obtain ZnO nanoparticles;

[0052] (2) Add ZnO nanoparticles and appropriate amount of titanium sulfate to 30mL ethanol to form a solution with a total concentration of 0.5M, in which the molar ratio of zinc:ti...

Embodiment 2

[0055] The following is the preparation of ZnO / TiO by using zinc nitrate, titanium nitrate, methanol, ethanolamine, and heptane 2 Core-shell nanoparticles are used as an example to describe in detail.

[0056] (1) First, add an appropriate amount of zinc nitrate to 50mL of methanol to form a solution with a total concentration of 0.2M. Then stir and dissolve at 60°C, add lye (prepared by dissolving ethanolamine in 10mL methanol), and in molar ratio, ethanolamine in the solution: Zn 2+ =1.8:1. Stirring was continued at 60 °C for 2 h to obtain a homogeneous clear solution. Subsequently, after the solution is cooled, it is precipitated with heptane, and after centrifugation, it is dissolved with a small amount of methanol (repeat the operation and wash 3 times) to obtain ZnO nanoparticles;

[0057] (2) Add ZnO nanoparticles and an appropriate amount of titanium nitrate to 30mL methanol to form a solution with a total concentration of 0.2M, in which the molar ratio of zinc:tita...

Embodiment 3

[0060] The following is the preparation of ZnO / TiO by using zinc chloride, titanium tetrachloride, propanol, lithium hydroxide, octane 2 Core-shell nanoparticles are used as an example to describe in detail.

[0061] (1) First, add an appropriate amount of zinc chloride to 50mL of propanol to form a solution with a total concentration of 1M. Then stir and dissolve at 60°C, add lye (prepared by dissolving lithium hydroxide in 10mL propanol), and the dissolved OH in the solution is - : Zn 2+ =2.5:1. Stirring was continued at 60 °C for 4 h to obtain a homogeneous clear solution. Subsequently, after the solution was cooled, it was precipitated with octane, and after centrifugation, it was dissolved with a small amount of propanol (repeated operation, washed 3 times) to obtain ZnO nanoparticles;

[0062] (2) Add ZnO nanoparticles and an appropriate amount of titanium tetrachloride to 30 mL of propanol to form a solution with a total concentration of 1 M, in which the molar rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com