Microwave sensor, microwave signal processing system and detection method thereof

A microwave sensor and microwave signal technology, which is applied in the field of microwave systems, can solve problems such as high cost and difficult production, and achieve the effects of cost reduction, flexible functions, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This program designs a microwave sensor, and a microwave signal processing system and detection method based on this sensor, which can be used for rapid food safety detection and quality control. Various devices or processes are described below to provide examples of each required implementation. Any embodiment described below does not limit any claimed embodiment, and any claimed embodiment may include processes or devices other than those described below. The claimed embodiments are not limited to devices or processes having all of the features of any one device or process described below, nor to features common to multiple or all devices described below.

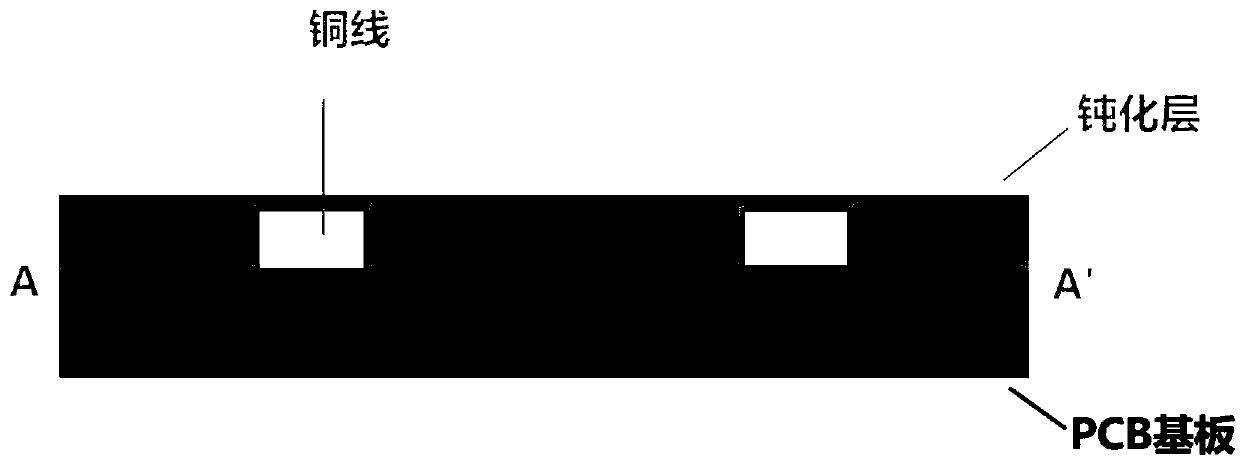

[0044]This solution provides a microwave sensor corresponding to a split ring resonator (SRR). In food safety testing and quality control, sensors are used to detect impurities in liquid samples to achieve real-time detection. There is a microwave circuit for analyzing the microwave signal reflected from the sens...

Embodiment 2

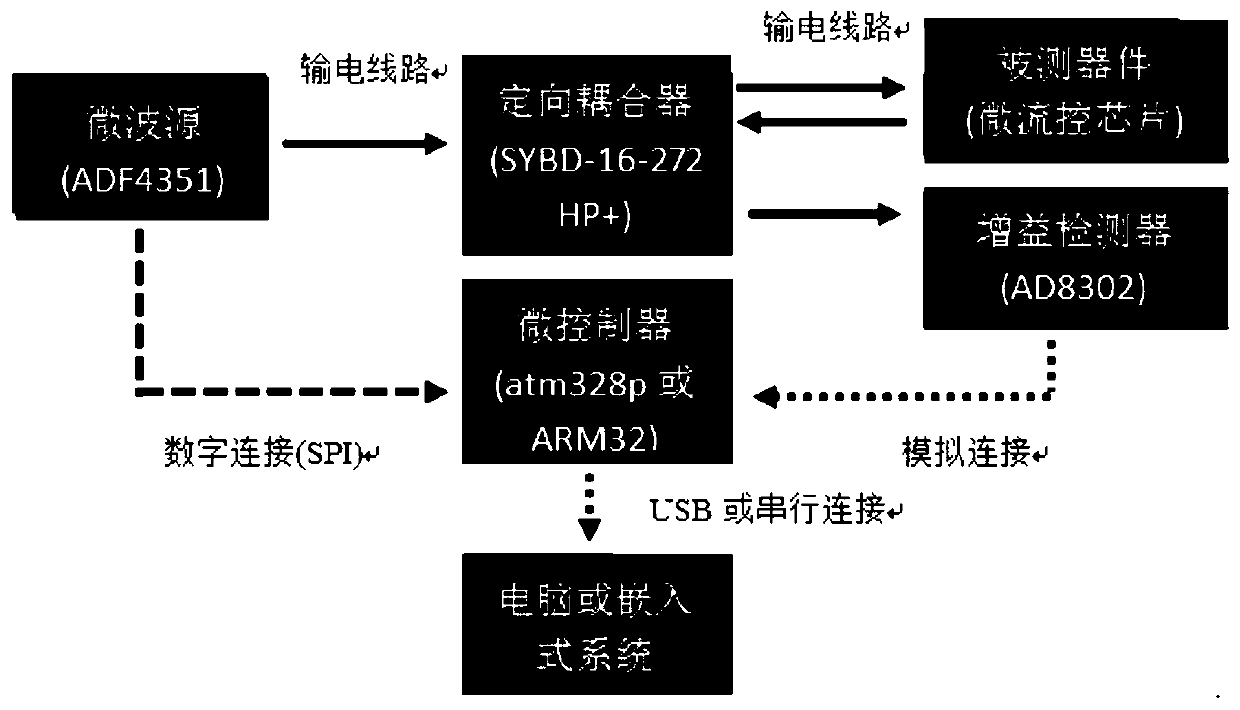

[0061] Such as image 3 As shown, this solution provides a schematic diagram of a microwave signal processing system. The system consists of three main subsystems, a combiner, a coupler and an amplitude and phase detector.

[0062] The specific microwave signal processing system consists of three main components, including the microcontroller of the PLL synthesizer, the directional coupler and the gain detector. A microcontroller is used to control the generation of microwave signals and collect amplitude and phase difference data from the amplitude-phase detector.

[0063] Microcontroller, the microcontroller includes the PLL synthesizer, the microcontroller controls the PLL synthesizer, data acquisition and communication with the PC. Here you can choose atm328p or ARM32 microcontroller;

[0064] A directional coupler, here a directional coupler is a two-way coupler, extracts the forward and backward microwave signals and sends them to a gain detector. The SYBD-16-272HP+ ...

Embodiment 3

[0072] Based on the system of Example 2, the corresponding microwave induction measurement method can be designed to be compatible with the lab-on-a-chip (LOC) method. Methods as below:

[0073] In the conventional detection, the device under test, that is, the microwave sensor is set in the liquid under test for detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com