An all-solid continuous fiber lithium-ion battery structure and its 3D printing forming method

A lithium-ion battery and continuous fiber technology, applied in structural parts, battery electrodes, secondary batteries, etc., can solve the problem of not fully utilizing the advantages of 3D printing, metal lithium can not be used in the air environment, lithium-ion battery structure optimization, etc. problem, to achieve the effect of effective charge conduction, good interface performance between layers, and simple and flexible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

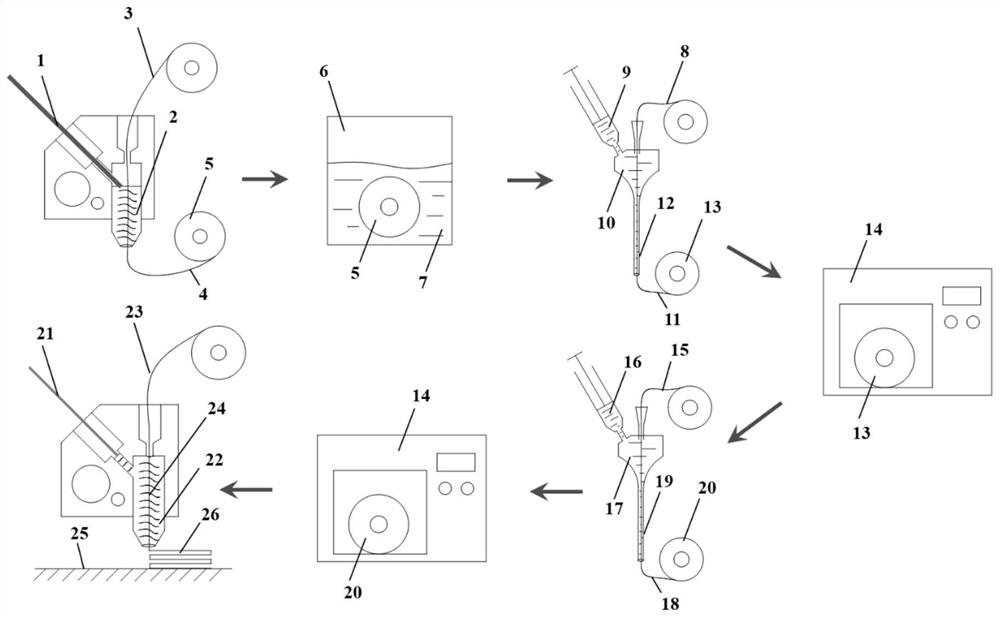

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0032] refer to figure 1 , a 3D printing method for an all-solid-state continuous carbon fiber lithium-ion battery, comprising the following steps:

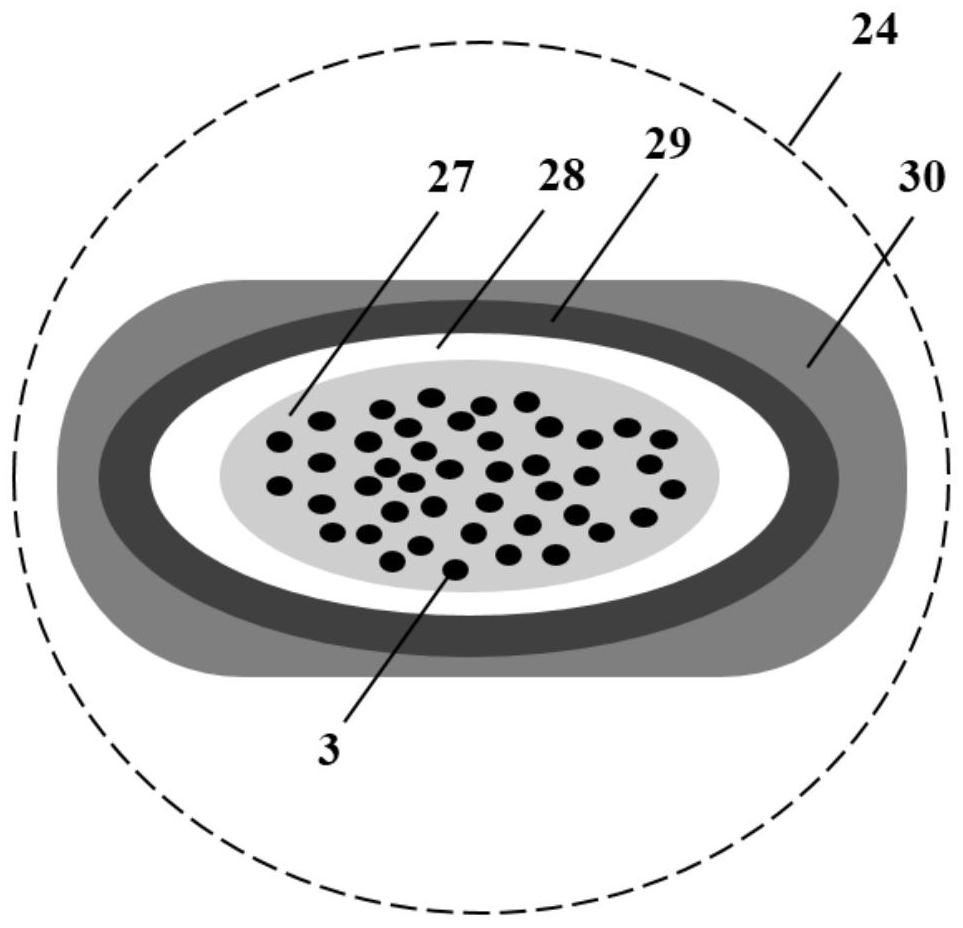

[0033] Step 1. After the metal wire 1 is fed into the first melting cavity 2 and melted, it is compounded with the continuous fiber 3 to obtain a uniform composite single bundle 4, and then the composite single bundle 4 is pulled out of the first melting cavity 2 and wound around the first melting cavity 2. On the wire reel 5, the metal wire 1 is a tin wire, and the continuous fiber 3 is a copper-coated carbon fiber;

[0034] Step 2, put the first wire disc 5 wound with the composite single bundle 4 into the container 6, and inject the acid solution 7 into the container 6 to corrode the composite single bundle 4, leave standstill and keep for 10min, and the acid solution is The mass fraction is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com