Epoxy-based alkene and alkene ether modified rosin phenol resin

A technology of epoxy olefin and rosinol, which is applied in the chemical modification of natural resins, adhesive additives, polymer adhesive additives, etc., can solve the problems of general tackifying effect and low reactivity, and achieve tackifying effect. Good, high reactivity, strong and stable colloidal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

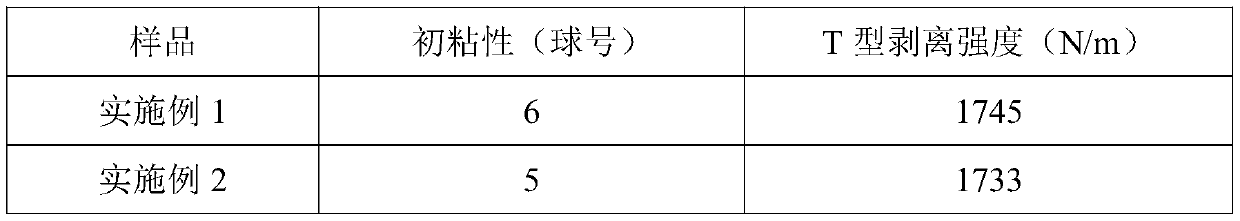

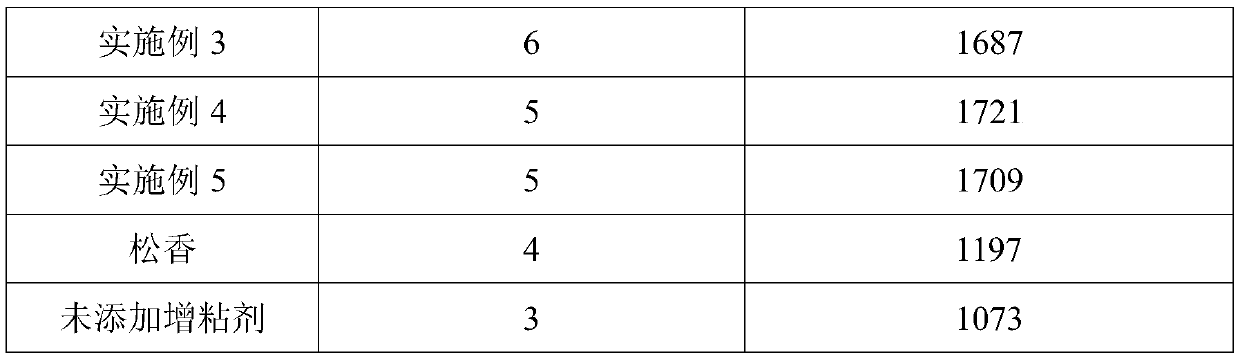

Examples

Embodiment 1

[0023] A preparation method of epoxy olefin and olefin ether modified rosin phenol resin, comprising the following steps:

[0024] S1. In parts by weight, add 100 parts of rosin to solvent A, then heat up to 210°C, add 25 parts of phenol source reagent after the rosin melts, then add 11 parts of acid catalyst, neutralize the acid catalyst after 10 hours of reaction, and then Adjust the temperature to 220° C. to obtain rosinol resin acid by distillation under reduced pressure, and recycle the obtained solvent A after cooling and separating, and the solvent A is toluene;

[0025] S2. In parts by weight, add 100 parts of rosin phenol resin acid prepared in S1 to solvent B, then heat up to 120°C, add 3 parts of organic alkali ammonium catalyst after melting the rosin phenol resin acid, and then dropwise add epoxy base olefin and alkene ether raw materials, the time for adding drops is 0.8h, then adjust the temperature to 110°C, and stop the reaction until the acid value of the pro...

Embodiment 2

[0035] A preparation method of epoxy olefin and olefin ether modified rosin phenol resin, comprising the following steps:

[0036] S1. In parts by weight, add 100 parts of rosin to solvent A, then heat up to 230°C, add 3 parts of phenol source reagent after the rosin melts, then add 0.2 parts of acid catalyst, neutralize the acid catalyst after reacting for 6 hours, and then The temperature is adjusted to 120 DEG C and distilled under reduced pressure to obtain rosinol resin acid, and the solvent A obtained by the reduced pressure distillation is recycled after cooling and separation. The solvent A is a mixture of methyl ethyl ketone, methyl isobutyl ketone and propyl acetate, and its weight The ratio is 2:4:3;

[0037] S2. In parts by weight, add 100 parts of rosin phenol resin acid prepared in S1 to solvent B, then heat up to 150°C, add 0.9 parts of organic alkali ammonium catalyst after melting the rosin phenol resin acid, and then dropwise add epoxy base olefin and alkene...

Embodiment 3

[0047] A preparation method of epoxy olefin and olefin ether modified rosin phenol resin, comprising the following steps:

[0048] S1. In parts by weight, add 100 parts of rosin to solvent A, then heat up to 50°C, add 30 parts of phenol source reagent after the rosin melts, then add 12 parts of acid catalyst, neutralize the acid catalyst after 2 hours of reaction, and then Adjust the temperature to 160° C. to obtain rosinol resin acid by distillation under reduced pressure, and recycle the solvent A obtained by the distillation under reduced pressure after cooling and separation, and the solvent A is 120# solvent gasoline;

[0049] S2. In parts by weight, add 100 parts of rosin phenol resin acid prepared in S1 to solvent B, then heat up to 50°C, add 0.2 parts of organic alkali ammonium catalyst after melting the rosin phenol resin acid, and then dropwise add epoxy Base olefin and olefin ether raw materials, the time for adding drops is 0.5h, then adjust the temperature to 180°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com