Adjustable dust flushing device for stainless steel saw-cutting and hot-rolling

A stainless steel, adjustable technology, applied in the attachments of sawing machines, metal sawing equipment, metal processing equipment, etc., can solve the problems of small spray area, can not solve the problem of sawing stainless steel, and increase the cost of sawing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 as well as Figure 8 The present invention is described in further detail.

[0032] An adjustable chip punching device for sawing hot-rolled stainless steel is used for sawing hot-rolled stainless steel bars.

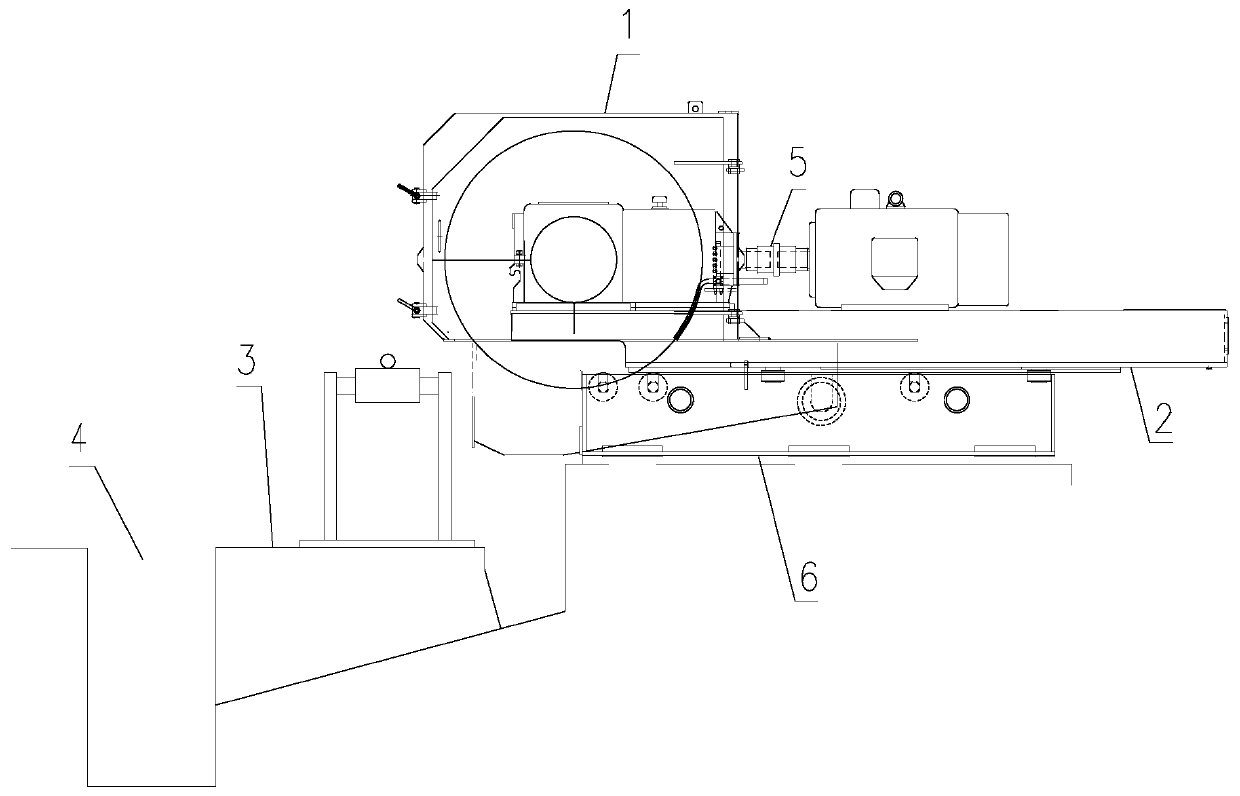

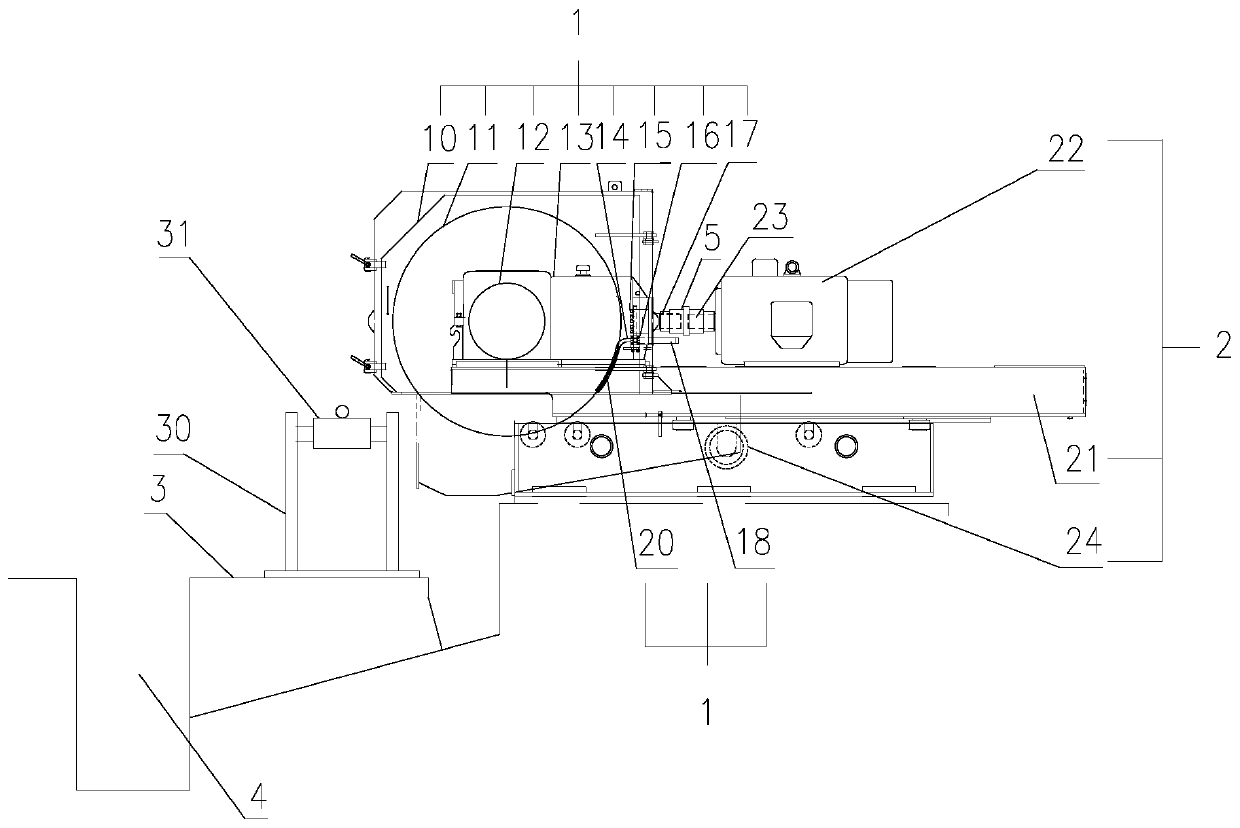

[0033] like figure 1 and figure 2 As shown, it includes a saw blade device 1 , a feeding device 2 , a sawing table 3 , a cutting pit 4 , a coupling 5 and a base 6 . The input shaft 17 of the saw blade device 1 is connected with one end of the shaft coupling 5, the other end of the shaft coupling 5 is connected with the output matching shaft 23 of the motor 22, and the lower end of the feeding device 2 is rollingly connected with the base 6, and the base One end of 6 is welded with the bottom of sawing table 3. The sawing table 3 is welded with the cutting pit 4.

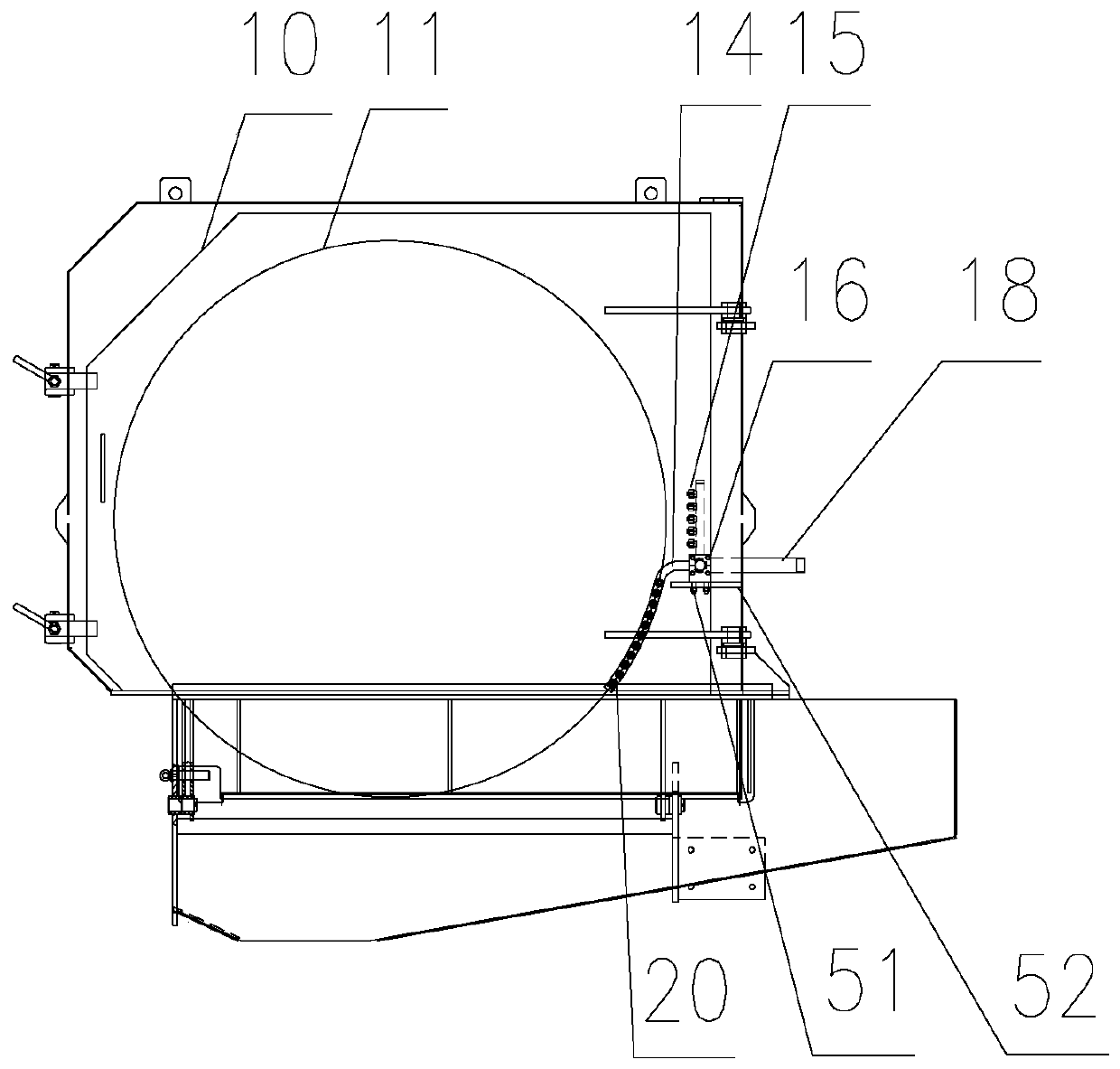

[0034] like figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 as well as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com