Ruthenium-titanium composite oxide modified by the third main group element and its preparation method and application

A titanium composite oxide, composite oxide technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, combustion methods, etc., can solve the problem of low stability, limited catalyst activity, toxicity and other problems, to achieve the effect of low complete conversion temperature, convenient and practical technical route, and strong anti-chlorine poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

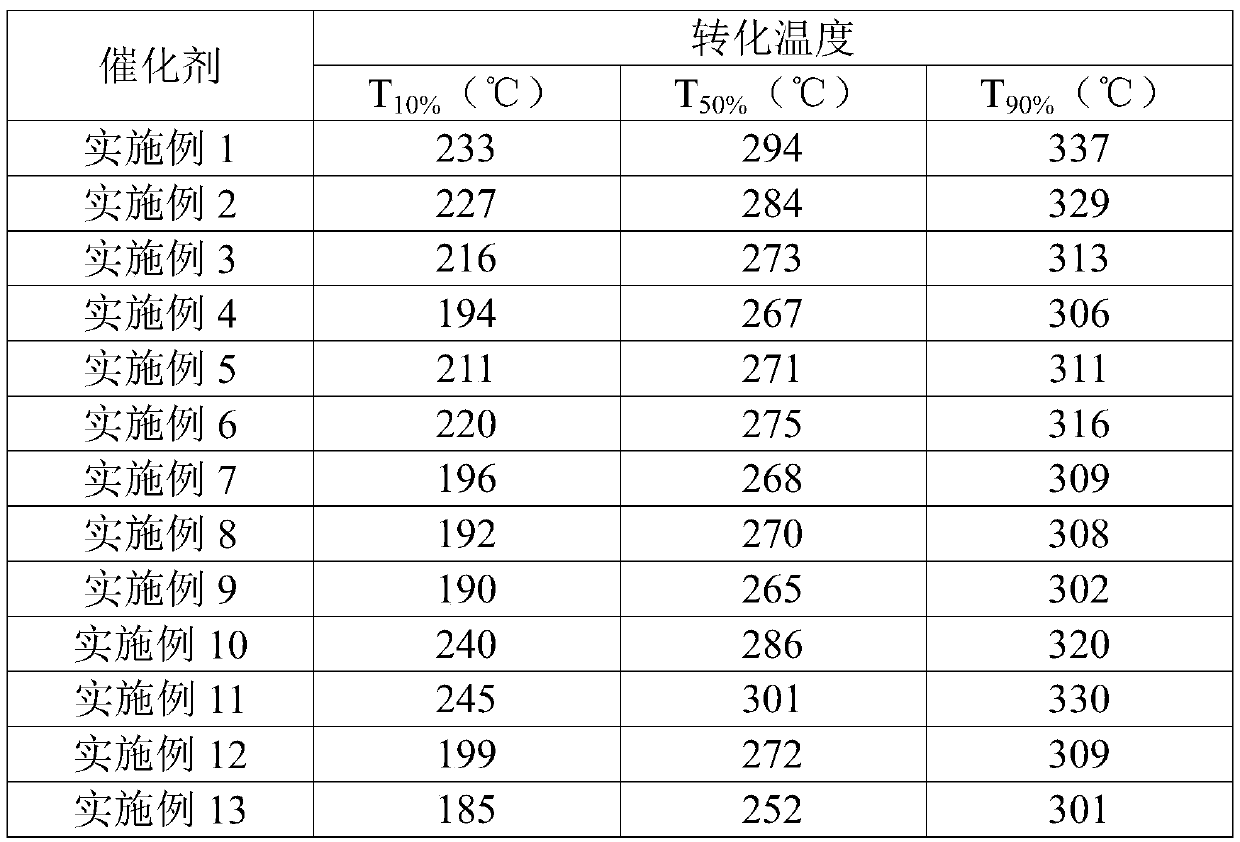

Examples

Embodiment 1

[0033] Weigh 14.2g of (CH 3 CH 3 CHO) 4 Dissolve Ti in 30ml of ethanol, stir for 1 hour, quickly drop 20ml of ethanol-water mixed solution to obtain a gel, dry at 110°C for 12 hours, and roast at 500°C for 4 hours to obtain a catalyst carrier; weigh 2g of TiO 2 Carrier, measure 1ml of RuCl 3 The solution (10 g / L concentration) was added to the crucible, about 1 ml of deionized water was added dropwise, and stirred repeatedly with a glass rod until uniformly mixed. After natural evaporation to dryness, place it in an oven at 110°C for overnight drying, and then bake at 400°C for 4 hours to obtain Ru / TiO 2 Catalyst, and test the catalytic effect of this catalyst on dichloromethane.

Embodiment 2

[0035] Weigh 14.07g of (CH 3 CH 3 CHO) 4 Ti and 0.14g Ga(NO 3 ) 3 ·xH 2 O was respectively dissolved in 30ml of ethanol and 30ml of ethanol-water mixed solution, and after stirring for 1 hour, the gallium salt solution was quickly poured into the titanium salt solution to obtain a gel, and then the resulting gel was dried at 110°C for 12 hours, and then dried at 500°C Calcined for 4 hours to prepare the catalyst carrier; weigh 2g of xGa-TiO2 Carrier, measure 1ml of RuCl 3 Add the solution (concentration: 10g / L) into the crucible, add about 1ml of deionized water dropwise, stir repeatedly with a glass rod until the mixture is uniform, dry it in an oven at 110°C overnight, and bake it at 400°C for 4 hours. Prepared Ru / 1%Ga-TiO 2 catalyst. The substance amount of the third main group element Ga accounts for 1% of the total amount of Ga and Ti substances, and the mass of ruthenium in the ruthenium-titanium composite oxide modified by the third main group element is 0.5%. T...

Embodiment 3

[0037] According to the same method as in Example 2, adjust the ratio of titanium salt and gallium salt to prepare Ru / 3%Ga-TiO 2 catalyst. The substance amount of the third main group element Ga accounted for 3% of the total amount of Ga and Ti, and the catalytic effect of the catalyst on dichloromethane was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com