SnO2-doped slurry, preparation method and application thereof

A slurry and powder technology, applied in the field of doped SnO2 slurry and its preparation, can solve the problems of poor printing effect, high viscosity of nano slurry, and uneven surface of thick film, and achieve good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

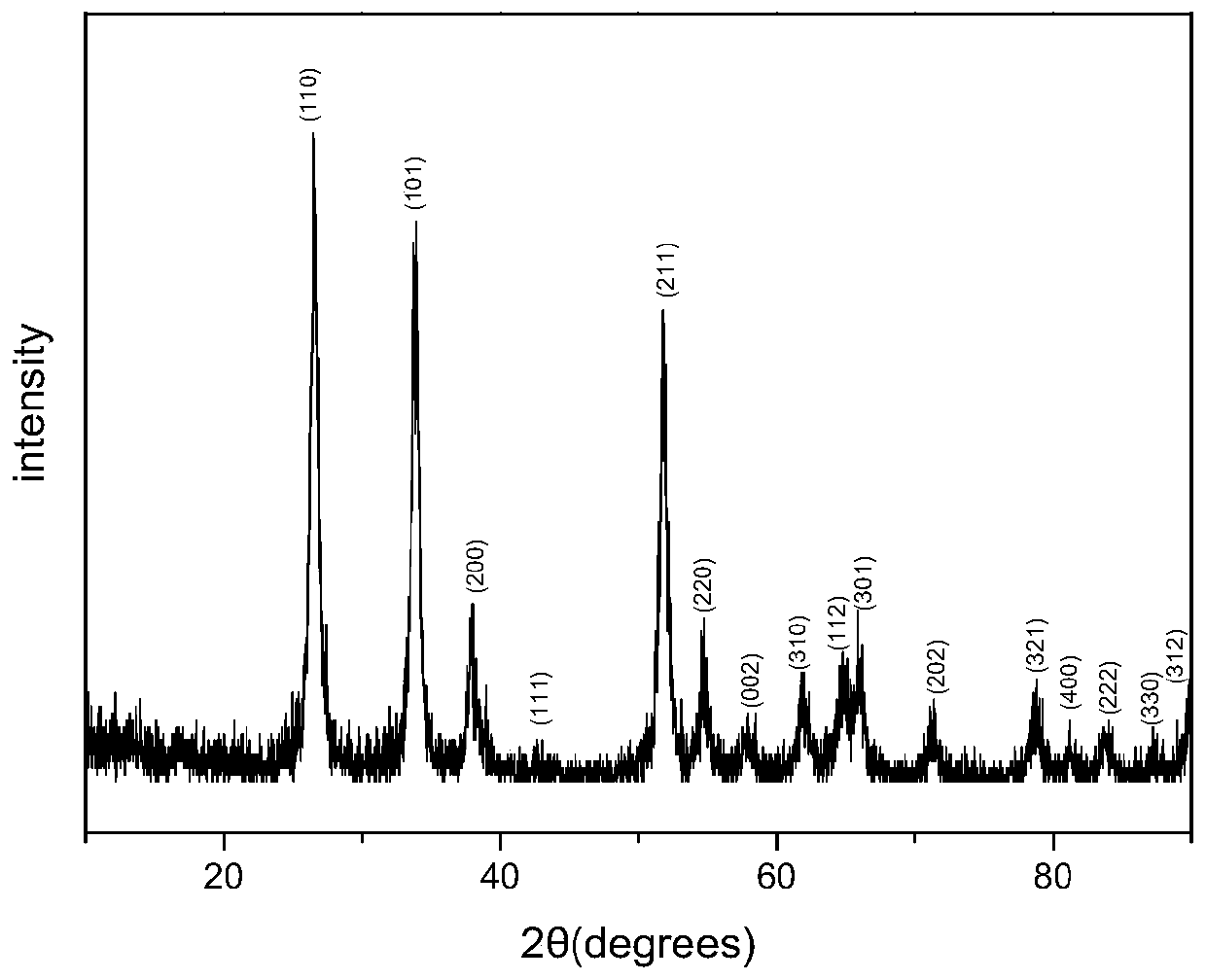

Image

Examples

Embodiment 1

[0066] Step 1. Weigh 35.91 g of terpineol and 15.39 g of butyl carbitol acetate in a beaker, and stir for 30 min with a magnetic stirrer to obtain a mixed solvent.

[0067] Step 2. Add 0.60g of dibutyl phthalate, 1.20g of dioctyl phthalate and 5.40g of ethyl cellulose to the mixed solvent in step 1. Put it in a water bath and heat it at 80°C. Stir with a stirrer for 2 h to mix to obtain an organic vehicle.

[0068] Step 3: Weigh 31.50g of nano-SnO 2 and 26.54g of palladium dispersion, ball milled for 10h, and the ball milling speed was 400r / min. After ball milling, dry at 60°C for 20 hours, and sieve through a 100-mesh sieve to obtain a mixed powder.

[0069] Step 4: Add the organic vehicle in step 2 to the mixed powder in step 3, and then add 0.315g, 0.473g, 0.630g and 0.7875g (accounting for 1wt%, 1.5wt%, 2wt% and 2.5wt%) tributyl phosphate, grind 35h with the roller mill, the rotating speed of the roller mill is set as 100r / min, obtain doped SnO 2 of slurry.

[0070] S...

Embodiment 2

[0072] Step 1. Weigh 35.91 g of terpineol and 15.39 g of butyl carbitol acetate in a beaker, and stir for 30 min with a magnetic stirrer to obtain a mixed solvent.

[0073] Step 2. Add 0.60g of dibutyl phthalate, 1.20g of dioctyl phthalate and 5.40g of ethyl cellulose to the mixed solvent in step 1. Put it in a water bath and heat it at 80°C. Stir with a stirrer for 2h to mix to obtain an organic vehicle.

[0074] Step three, weigh 31.50g of nano-SnO 2 and 26.54g of palladium dispersion, ball milled for 10h, and the ball milling speed was 400r / min. After ball milling, dry at 60° C. for 20 h, and sieve through a 100-mesh sieve to obtain a mixed solid powder.

[0075] Step 4: Add the organic vehicle in step 2 to the mixed powder in step 3, then add 0.315g, 0.473g and 0.630g (accounting for 1wt%, 1.5wt% and 2wt% of the mixed powder mass respectively) of three Ethanolamine was ground for 35 hours with a roller mill, and the speed of the roller mill was set at 100r / min to obtain...

Embodiment 3

[0078] Step 1. Weigh 35.91 g of terpineol and 15.39 g of butyl carbitol acetate in a beaker, and stir for 30 min with a magnetic stirrer to obtain a mixed solvent.

[0079] Step 2. Add 0.60g of dibutyl phthalate, 1.20g of dioctyl phthalate and 5.40g of ethyl cellulose to the mixed solvent in step 1. Put it in a water bath and heat it at 80°C. Stir with a stirrer for 2h to mix to obtain an organic vehicle.

[0080] Step three, weigh 31.50g of nano-SnO 2 and 26.54g of palladium dispersion, ball milled for 10h, and the ball milling speed was 400r / min. After ball milling, dry at 60°C for 20 hours, and sieve through a 100-mesh sieve to obtain a mixed powder.

[0081] Step 4. Add the organic vehicle described in step 2 to the mixed powder described in step 3, and then add 0.315g, 0.473g, 0.630g, 0.7875g and 0.945g (accounting for 1wt% of the mixed powder mass respectively, 1.5wt%, 2wt%, 2.5wt% and 3wt%) oleic acid, grind 35h with the roller mill, the rotating speed of the roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com