Preparation method of polyester sun-shading cloth

A technology of sunshade cloth and polyester, applied in the field of polyester fiber, can solve the problem of high thermal shrinkage rate of sunshade cloth, and achieve the effects of reducing entanglement, reducing shrinkage rate, and improving tensile strength and peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

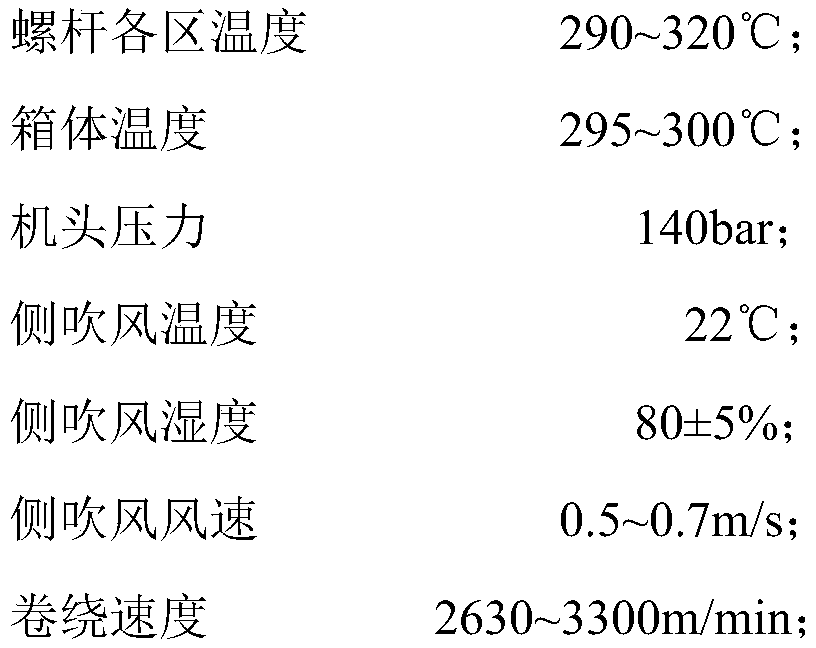

Embodiment 1

[0064] The preparation method of polyester sunshade cloth, the steps are as follows:

[0065] (1) prepare modified polyester;

[0066](1.1) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after mixing palladium acetate and dimethyl di-tert-butylethylene, add mass concentration It is 10% hydrogen peroxide solution, reacted at 72°C for 3 hours, cooled, crystallized and refined to obtain 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, wherein The mass ratio of dimethyldi-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:2.0:0.015, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as follows Shown in formula (I);

[0067] (1.2) Preparation of doped modified Sb 2 o 3 ;

[0068] (a) Mg(NO 3 ) 2 aqueous solution with a concentration of 8 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, the Mg in the mixture 2+ with Sb 3+ The molar ratio is 2:100;

[0069] (b) Add dropw...

Embodiment 2

[0085] The preparation method of polyester sunshade cloth, the steps are as follows:

[0086] (1) prepare modified polyester;

[0087] (1.1) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after mixing palladium acetate and dimethyl di-tert-butylethylene, add mass concentration It is 11% hydrogen peroxide solution, reacted at 70°C for 4 hours, cooled, crystallized and refined to obtain 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, wherein The mass ratio of dimethyldi-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:1.8:0.015, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as follows Shown in formula (I);

[0088] (1.2) Preparation of doped modified Sb 2 o 3 ;

[0089] (a) The concentration of 0.5mol% Ca(NO 3 ) 2 Aqueous solution with a concentration of 5 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, the Ca in the mixture 2+ with Sb 3+ The molar ratio is ...

Embodiment 3

[0102] The preparation method of polyester sunshade cloth, the steps are as follows:

[0103] (1) prepare modified polyester;

[0104] (1.1) Synthesis of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, the method is: after mixing palladium acetate and dimethyl di-tert-butylethylene, add mass concentration It is 12% hydrogen peroxide solution, reacted at 74°C for 4 hours, cooled, crystallized and refined to obtain 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, wherein The mass ratio of dimethyldi-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:1.6:0.015, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol is as follows Shown in formula (I);

[0105] (1.2) Preparation of doped modified Sb 2 o 3 ;

[0106] (a) Ba(NO 3 ) 2 Aqueous solution with a concentration of 10 mol% Sb 2 o 3 The solution is mixed evenly, Sb 2 o 3 The solvent of the solution is oxalic acid, Ba in the mixture 2+ with Sb 3+ The molar ratio is 3:100;

[0107] (b) Add dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com