Method for cultivating monoraphidium sp. to produce biodiesel by using walnut shell extracting solution

The technology of single needle algae and walnut shell is applied in the field of biodiesel, which can solve the problems of complex extraction process, long cultivation time, low oil yield and the like, achieves simple and easy method, increases utilization efficiency, and improves single needle algae oil production. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

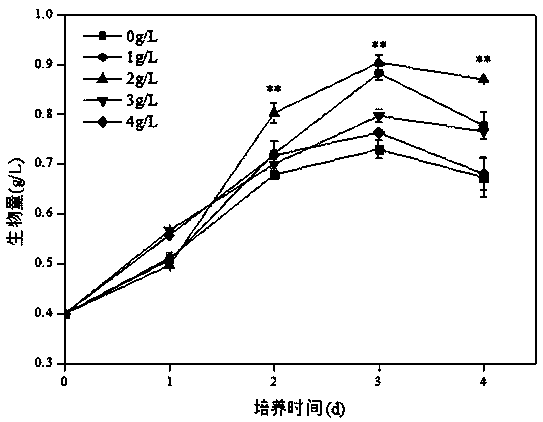

[0036] Embodiment 1: a kind of method that utilizes walnut shell extract to cultivate monopodella to produce biodiesel, the specific steps are:

[0037] (1) Add water to the walnut shell and boil for more than 4 hours until the mass ratio of the liquid in the system to the walnut shell is 8:1, separate the solid from the liquid, and use the liquid as the basal medium, add glucose to the basal medium, and use sodium hydroxide The solution adjusts the pH value of the culture medium to 6.82, and then sterilizes to obtain the monospora culture medium; wherein the solid-liquid ratio g:L of glucose to the basic culture medium is 1:1;

[0038] (2) Inoculate Monospiria into the culture medium of Monospiria in step (1), and then cultivate it under the condition of temperature of 25°C and light intensity of 6800 lux; wherein Monospiria is Monospiria Monoraphidium For sp.QLZ-3, the inoculum amount of Monospinatus is 0.4g / L;

[0039] (3) Determination of the biomass of Monopodella under ...

Embodiment 2

[0046] Embodiment 2: a kind of method that utilizes walnut shell extract to cultivate monopodella to produce biodiesel, the specific steps are:

[0047] (1) Add water to the walnut shell and boil for more than 4 hours until the mass ratio of the liquid in the system to the walnut shell is 8:1, separate the solid from the liquid, and use the liquid as the basal medium, add glucose to the basal medium, and use sodium hydroxide The solution adjusts the pH value of the culture medium to 7.00, and then sterilizes to obtain the monospora culture medium; wherein the solid-liquid ratio g:L of glucose to the basic culture medium is 2:1;

[0048] (2) Inoculate Monospiria into the culture medium of Monospiria in step (1), and then culture it under the condition of temperature of 24°C and light intensity of 6900 lux; wherein Monospiria is Monospiria Monoraphidium For sp.QLZ-3, the inoculum amount of Monospinatus is 0.4g / L;

[0049] (3) Determination of the biomass of Monopodella under th...

Embodiment 3

[0056] Embodiment 3: a kind of method that utilizes walnut shell extract to cultivate monopodella to produce biodiesel, the specific steps are:

[0057] (1) Add water to the walnut shell and boil for more than 4 hours until the mass ratio of the liquid in the system to the walnut shell is 24:1, separate the solid from the liquid, and use the liquid as the basal medium, add glucose to the basal medium, and use sodium hydroxide The solution adjusts the pH value of the culture medium to 6.96, and then sterilizes to obtain the monostipium culture medium; wherein the solid-liquid ratio g:L of glucose to the base medium is 3:1;

[0058] (2) Inoculate Monospiria into the culture medium of Monospiria in step (1), and then culture it under the condition of temperature of 26°C and light intensity of 6800 lux; wherein Monospiria is Monospiria Monoraphidium For sp.QLZ-3, the inoculum amount of Monospinatus is 0.4g / L;

[0059] (3) Determination of the biomass of Monospina under the cultur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com