Preparation method and application of fatty acid modified caramel pigment

A technology of fatty acid modification and caramel pigment, applied in chemical instruments and methods, azo dyes, organic dyes, etc., to achieve high fat solubility, improved thermal stability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of production method that stearic acid modified caramel pigment is prepared as modifying agent with stearyl chloride, comprises the steps:

[0023] (1) Dissolve 0.5g of raw caramel and 3.3ml of stearyl chloride in a mixed solvent of 4ml of anhydrous DMF and 1ml of anhydrous DMSO, use 0.79ml of anhydrous pyridine as a catalyst, and heat at room temperature for 6h. Add an appropriate amount of distilled water to the reaction system, stir slightly, and quench the reaction. The reaction solution was suction-filtered, washed with a large amount of absolute ethanol, and the solid part was dried overnight in an oven at 60° C. to obtain 0.69 g of reddish-brown stearic acid-modified caramel pigment.

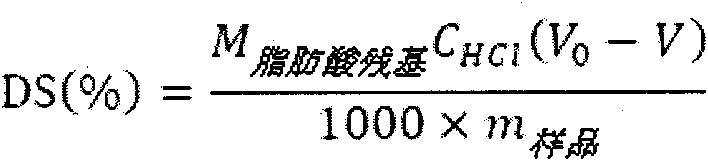

[0024] (2) Determination of the degree of substitution of the sample: the degree of substitution of the stearoyl chloride-modified caramel pigment was determined by saponification method. Its calculation formula is;

[0025]

[0026] Among them, M fatty acid residue: th...

Embodiment 2

[0036] Application of a stearic acid modified caramel coloring in edible oil coloring

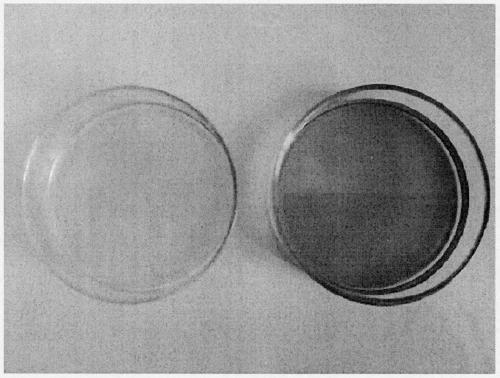

[0037] Weigh 0.01 g of the stearic acid-modified caramel pigment prepared in Example 1, dissolve it in 10 ml of edible oil, shake it in a constant temperature water bath shaker at 30 ° C for 2 h, centrifuge at 2500 r / min for 10 min, and take the supernatant for determination For its color ratio, red index and yellow index, edible oil was used as a blank control. Its color index is 131666.7 EBC units, its red index is 2.289657, and its yellow index is 3.491824. For the comparison chart of caramel pigment modified with stearyl chloride and edible oil, see Figure 1-2 .

Embodiment 3

[0039] A kind of production method of the caramel pigment of stearic acid modification, comprises the steps:

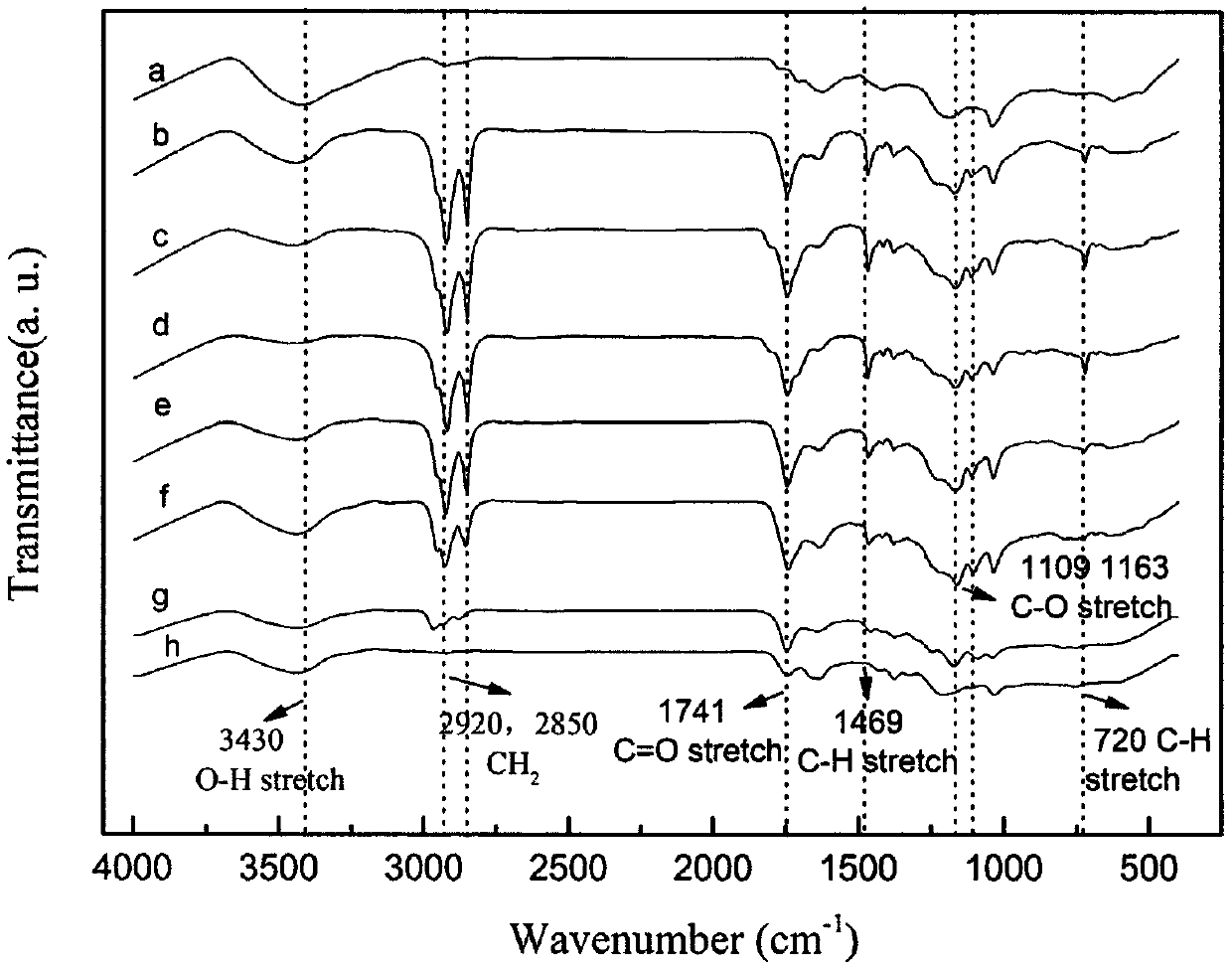

[0040] Dissolve 0.5 g of raw caramel and 3.3 ml of stearyl chloride in a mixed solvent of 3 ml of anhydrous DMF and 2 ml of anhydrous DMSO, use 0.79 ml of anhydrous pyridine as a catalyst, and heat at room temperature for 6 h. Add an appropriate amount of distilled water to the reaction system, stir slightly, and quench the reaction. The reaction solution was suction-filtered, washed with a large amount of absolute ethanol, and the solid part was dried overnight in an oven at 60°C to obtain 0.58 g of reddish-brown stearoyl chloride-modified caramel pigment, with an ester-water partition coefficient of 4.21 and a degree of substitution of 2.73, adding stearic acid-modified caramel pigment has a color rate of 103921.7 EBC units, a red index of 2.16, and a yellow index of 3.23537. The infrared spectrum is shown in Picture 1-1 in c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yellowness index | aaaaa | aaaaa |

| yellowness index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com