Core-shell structure acrylate emulsion, preparation method and applications thereof

An acrylate, core-shell structure technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of low chemical resistance, low fullness, low gloss of film formation, etc., and achieve the effect of high density and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

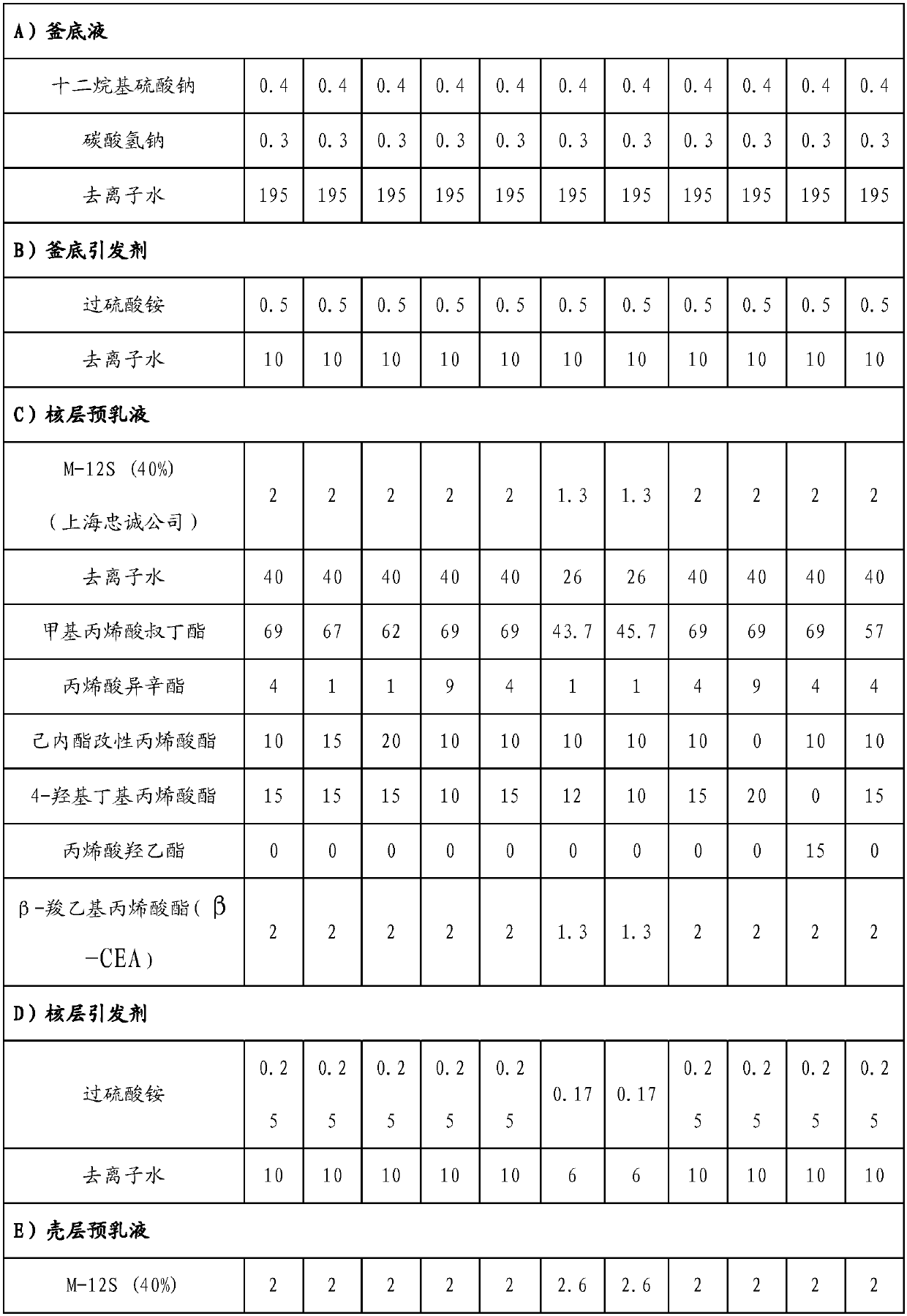

[0046] Preparation of S1 Acrylate Emulsion:

[0047] 1) Preparation of mixed monomer I: 69 parts (parts by mass, the same below) of tert-butyl methacrylate, 4 parts of isooctyl acrylate, and 10 parts of caprolactone-modified acrylate (PLACCEL FA2 of Daicel Company, caprolactone The lactone repeating unit is 2), 15 parts of 4-hydroxybutyl acrylate, and 2 parts of β-CEA (Solvay Company) are mixed to form a mixed monomer I;

[0048] 2) Preparation of mixed monomer II: 60 parts of tert-butyl methacrylate, 8 parts of isooctyl acrylate, 10 parts of caprolactone-modified acrylate (PLACCEL FA2, the number of caprolactone repeating units is 2), 20 parts Parts of 4-hydroxybutyl acrylate, 2 parts of β-CEA, and 8 parts of n-dodecyl mercaptan (chain transfer agent) are mixed to make mixed monomer II;

[0049] 3) Prepare the core layer pre-emulsion: add the mixed monomer I, 40 parts of water, and 0.8 part of M-12S (Shanghai Zhongcheng Company) emulsifier into the pre-emulsification kettle,...

Embodiment 2-8

[0055] Embodiment 2-8 prepares respectively S2-S8 acrylate emulsion successively

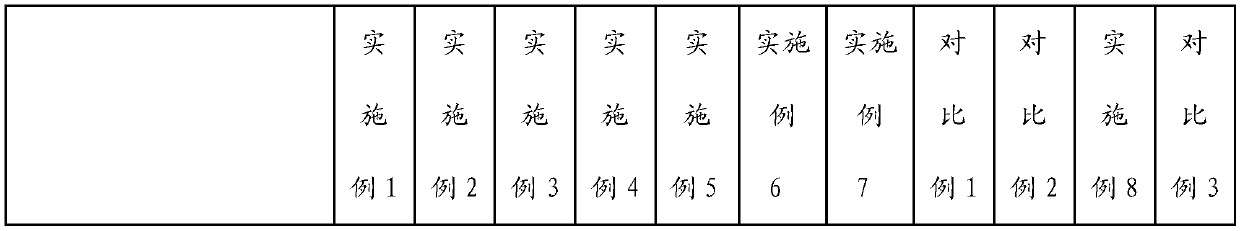

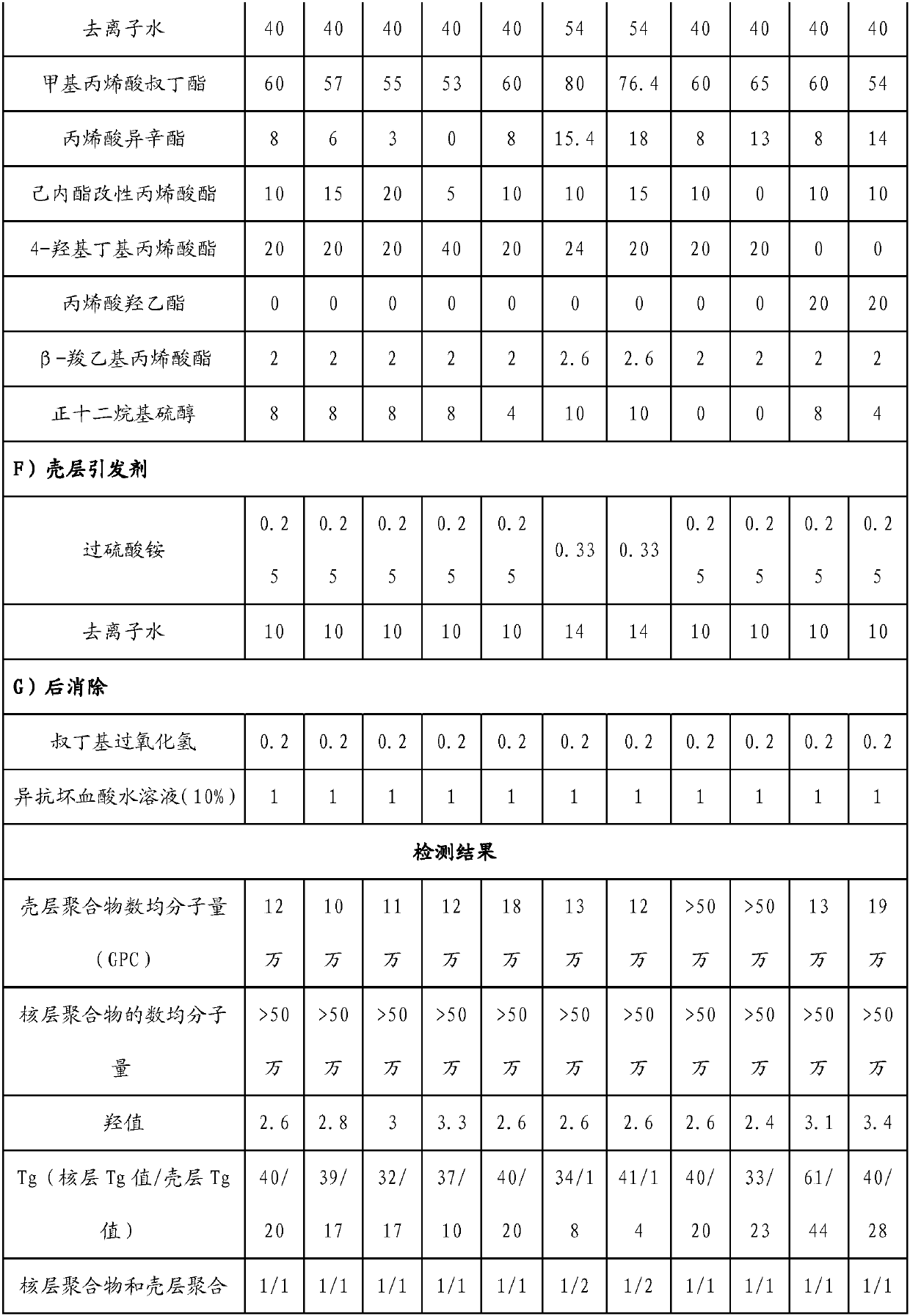

[0056] Using the same polymerization method as the S1 acrylate emulsion, the formula was changed according to the following Table 1 to prepare S2-S8 acrylate emulsions, all in the table are parts by mass. Wherein, the caprolactone-modified acrylate used in embodiment 2-6 is identical with embodiment 1, and the caprolactone-modified acrylate used in embodiment 7 is the PLACCEL FA4 of Daicel Company (caprolactone repeating unit number is 4).

Embodiment 9

[0066] The core-shell acrylate emulsions S1-S11 prepared in Examples 1-8 and Comparative Examples 1-3 were used to prepare one-component amino baking varnishes for testing their application properties. The formula of water-based amino white baking varnish is shown in Table 2.

[0067] Table 2

[0068]

[0069]

[0070] According to the formula in Table 2 above, first add 60g of water, 10g of BYK-190, 0.2g of Tego901W, 2g of Surfynol 140BC into the dispersion tank, and stir at 800r / min for 10min. Add 200g R-706 to increase the speed to 2000r / min, and after high-speed dispersion is uniform, add zirconium beads equal to the volume of the pigment and filler R-706, and grind the slurry to a fineness of ≤15μm.

[0071] Reduce the rotation speed to 800r / min, add 500g of emulsion under stirring, add an appropriate amount of DMEA to adjust the pH at 8.0-9.0, then add 125g of Cytec 325, 20g of dipropylene glycol butyl ether, 10g of ethylene glycol butyl ether, 5g of Tego Wet270, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com