A kind of treatment fluid and its application and metallization product and method

A technology for treating liquid and metallization, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as incomplete coating and selective metallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

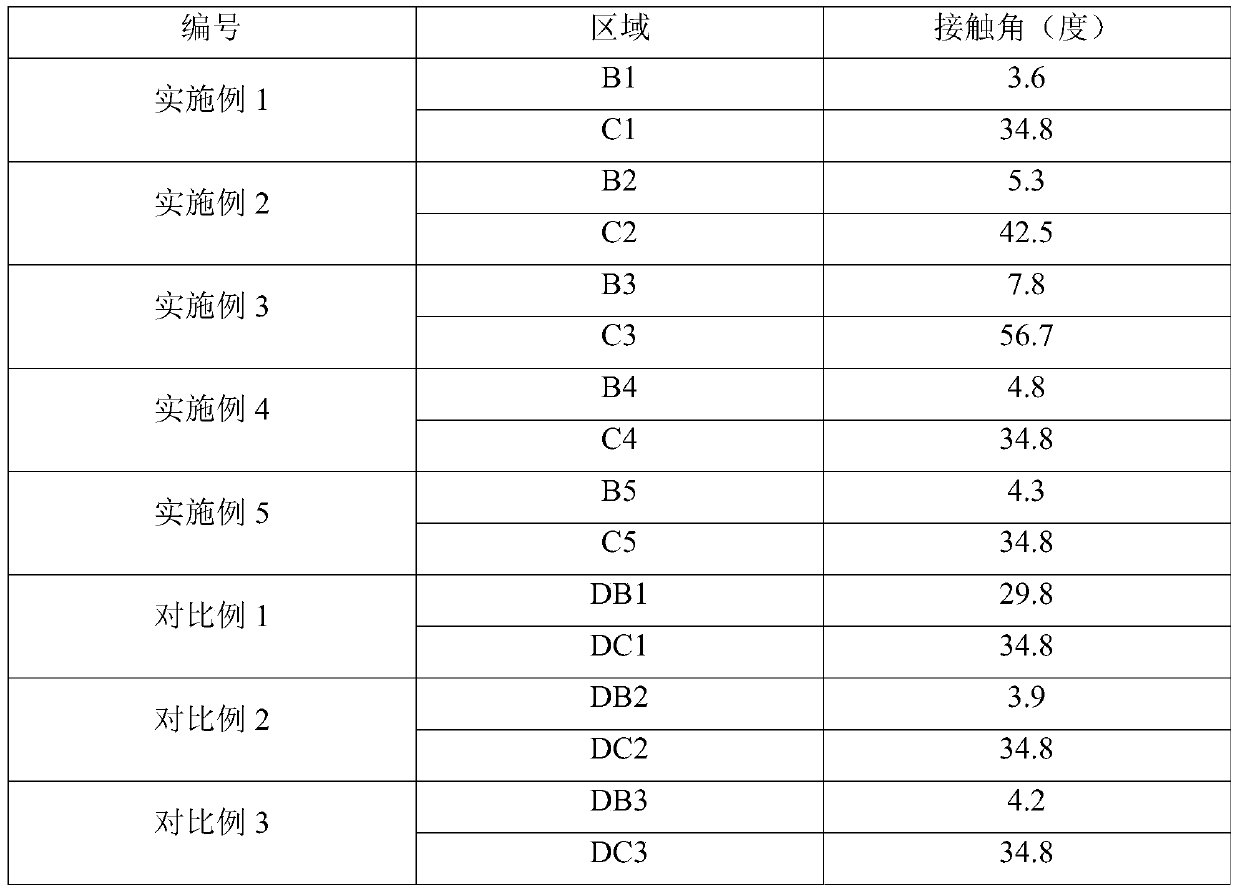

Examples

preparation example Construction

[0028] The present invention does not specifically limit the preparation method of the treatment liquid, as long as the above-mentioned components in the treatment liquid can be uniformly mixed. According to a specific embodiment, the treatment solution is prepared in the following manner: adding titanate, silicate and complexing agent into a solvent, and then stirring and reacting at 50-100° C. for 1-5 hours, and then at 10 Let stand at -30°C for 1-10 hours, then add cellulose and leveling agent and stir the reaction for 1-10 minutes.

[0029] The invention also provides the application of the treatment liquid in the selective metallization of the substrate surface.

[0030] The present invention also provides a metallized product, wherein the metallized product includes a substrate, a photolithographic pattern layer and a metal layer sequentially attached on the surface of the substrate, and the photolithographic pattern layer is formed by the above-mentioned treatment liqui...

preparation example 1

[0049] This preparation example is used to illustrate the treatment liquid provided by the present invention and its preparation method.

[0050] Add 14g of butyl acetate, 25g of ethanol and 25g of isopropanol into a 150mL three-necked flask equipped with a water separator, reflux condenser, stirrer and thermometer, stir evenly, slowly add 20g of 3-hydroxybutanone under stirring, add Stir for 10 minutes after completion, then slowly add 10g tetrabutyl titanate and 5g tetraethyl silicate dropwise, raise the temperature to 60°C and stir for 3h after the dropwise addition, then let stand at 25°C for 8h, then in Add 0.8g of hydroxyethyl cellulose (number average molecular weight: 100,000) and 0.05g of leveling agent BYK333 under stirring, and stir for 5 minutes to obtain a treatment solution, which is designated as A1.

preparation example 2

[0052] This preparation example is used to illustrate the treatment liquid provided by the present invention and its preparation method.

[0053] Add 15g of butyl acetate, 15g of ethyl acetate, 20g of methanol and 25g of butanol into a 150mL three-necked flask equipped with a water separator, reflux condenser, stirrer and thermometer, stir evenly, slowly add 15g of acetylacetone under stirring, add Stir for 10 minutes after the completion, then slowly add 5g tetraisopropyl titanate and 3g tetrabutyl silicate dropwise, after the dropwise addition, raise the temperature to 70°C and stir for 2h, then stand at 20°C for 8h, then Add 0.5g of hydroxyethyl cellulose (number average molecular weight: 200,000) and 0.05g of leveling agent BYK333 under stirring, and stir for 5 minutes to obtain a treatment solution, which is designated as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com